Treatment method of nut grains and special compound thickening agent thereof

A processing method and thickener technology, applied in the fields of application, food science, food preservation, etc., can solve the problems of complex components of preservatives, affecting the flavor of nuts, and not being universal, so as to improve the taste and increase the density , Inhibit the effect of water absorption and softening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: the processing of walnut grain

[0039] 1) Pelleting treatment: walnut grains are chopped (about 0.5cm) by a granulator;

[0040] 2) Soaking treatment: add chopped walnut grains to 30 times the water of its mass, and simultaneously add 3% of its mass of tansy seasoning bag, its mass of 0.1% of tea polyphenols, and add salt to a final concentration of 1%. , calcium chloride to a final concentration of 0.5%, soaking for 8 hours;

[0041] 3) Cleaning treatment: soak in water (the time is controlled within 20 minutes), until there is no soaking liquid residue on the surface of the walnut grains;

[0042] 4) Preparation of the transparent colloidal solution of the shell: prepare a colloidal solution containing 1% gellan gum and 1% sodium alginate, and control the solution temperature at 80°C;

[0043] 5) Preparation of the shell transparent colloid: put the processed walnut grains into the colloid solution and soak for 30 minutes, remove and filter the aqueou...

Embodiment 2-8

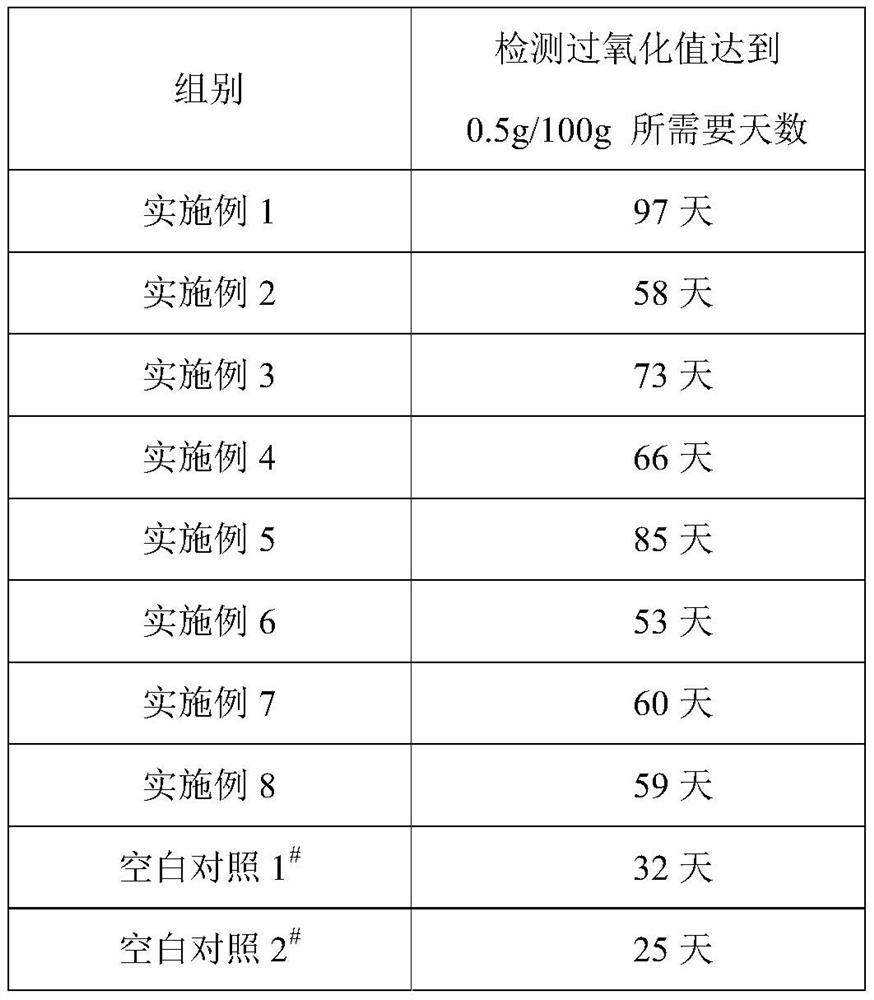

[0048] Adjust the consumption of each raw material and the soaking time of step 2) (specifically see the following table 1), all the other are with embodiment 1.

[0049] Table 1: the consumption of each raw material of embodiment 1-8

[0050]

[0051] blank control sample 1 # :

[0052] 1) Walnut grains are cleaned;

[0053] 2) Pelletizing treatment: cut the walnuts into the required particle size by a pelletizer.

[0054] blank control sample 2 # :

[0055] 1) Walnut grains are cleaned;

[0056] 2) Pelleting treatment: the walnut grains are cut into the required particle size by a granulator;

[0057] 3) Microwave treatment, the temperature is controlled at 140° C., the baking time is controlled at 6 minutes, and the moisture content is controlled within 15%.

Embodiment 9

[0078] Embodiment 9: the processing of peanut grain

[0079] 1) Pelleting treatment: chop the peanuts (below 0.5cm) by a granulator;

[0080] 2) Soaking treatment: add the chopped peanuts into water, 30 times the water of its mass, add tansy seasoning bag of 2% of its mass, tea polyphenols of 0.2% of its mass, and add salt to a final concentration of 1%, calcium chloride to a final concentration of 0.5%, soaking for 8 hours;

[0081] 3) Cleaning treatment: wash with water until there is no soaking liquid residue on the surface of peanut grains;

[0082] 4) Preparation of the transparent colloidal solution of the shell: prepare a colloidal solution containing 1% gellan gum and 1% sodium alginate, and control the solution temperature at 80°C;

[0083] 5) Preparation of the shell transparent colloid: put the processed peanuts into the colloid solution and soak for 30 minutes, remove and filter the aqueous solution;

[0084] 6) Freezing treatment: put the dried peanuts in a fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com