Composite material, curable composition, and method for producing curable composition

A technology of curable composition and composite material, which is used in the manufacture of curable composition and the field of composite materials for repairing dental filling and restorative materials, and can solve the problems of difficult dentin surface color tone, difficult to cause structural color and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0194] Hereinafter, the present invention will be further specifically described by way of examples, but the present invention is not limited by these examples.

[0195] The composite materials of Examples and Comparative Examples were all obtained by curing a curable composition containing a polymerizable monomer, inorganic particles, and a polymerization initiator. First, each component used for the curable composition of an Example and a comparative example is demonstrated.

[0196] 1. Polymerizable monomer

[0197] As polymerizable monomers, polymerizable monomer mixtures having the compositions shown in Table 1, that is, M1 and M2 were used. In addition, the abbreviations in the polymerizable monomer column in a table|surface represent the following compounds, respectively, and the number in parentheses represents the mass part used.

[0198] UDMA: 1,6-bis(methacryloylethyloxycarbonylamino)trimethylhexane

[0199] 3G: Triethylene glycol dimethacrylate

[0200] bis-GMA...

reference example 1

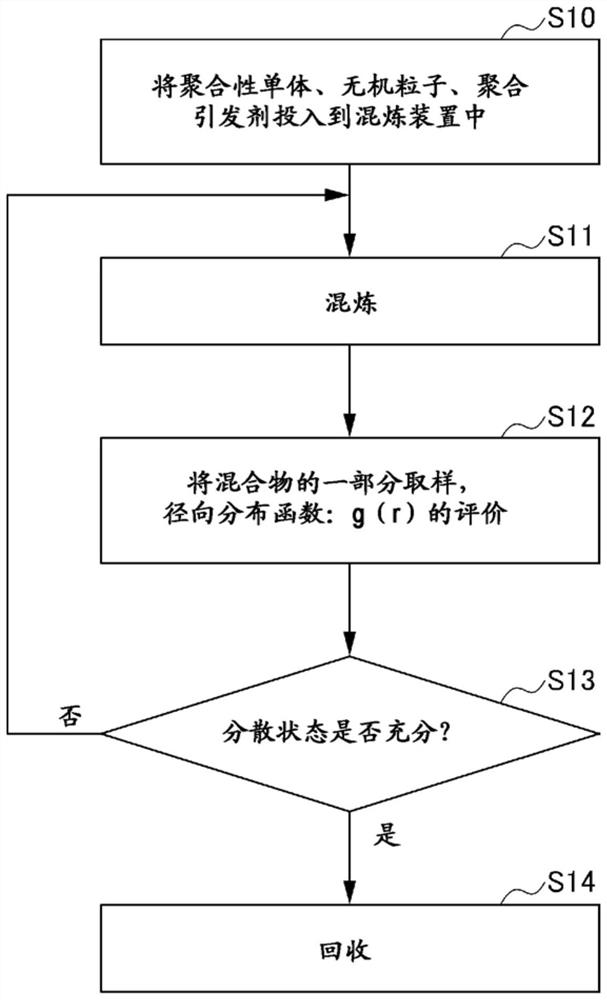

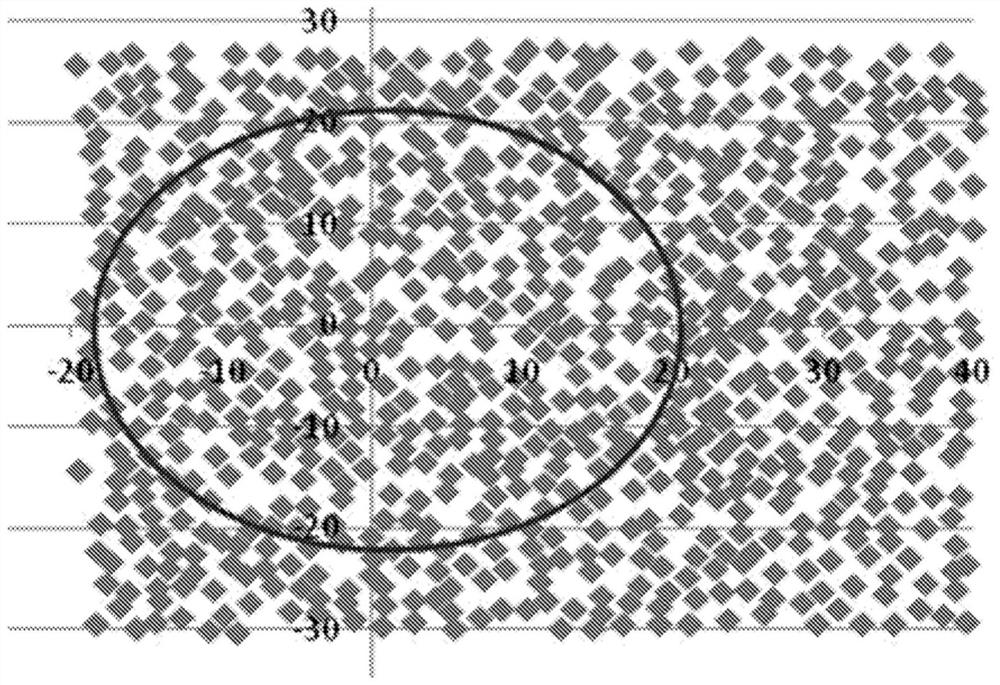

[0239] according to figure 1 The flow chart of the following method was used to manufacture the curable composition of Reference Example 1. Specifically, CQ: 4.8 g, DMBE: 16.0 g, and HQME: 2.4 g were added and mixed with respect to the polymerizable monomer mixture M1: 1600 g, and a uniform polymerizable monomer composition was prepared. Next, G-PID4: 6400g was weighed, and the above-mentioned polymerizable monomer composition was gradually added under red light, and the capacity of the stirring container was 15 L. ), kneading for 2 hours under the condition that the rotating speed of the stirring paddle was 7rpm~10rpm. The kneading was temporarily stopped, and 5.0 g of the mixture was sampled. This sample was degassed under reduced pressure at a pressure of 1000 Pa for 5 minutes, and irradiated with light for 30 seconds by a visible light irradiator (manufactured by Tokuyama Corporation, POWER LIGHT) to be cured. Regarding the obtained cured body, the radial distribution f...

Embodiment 1

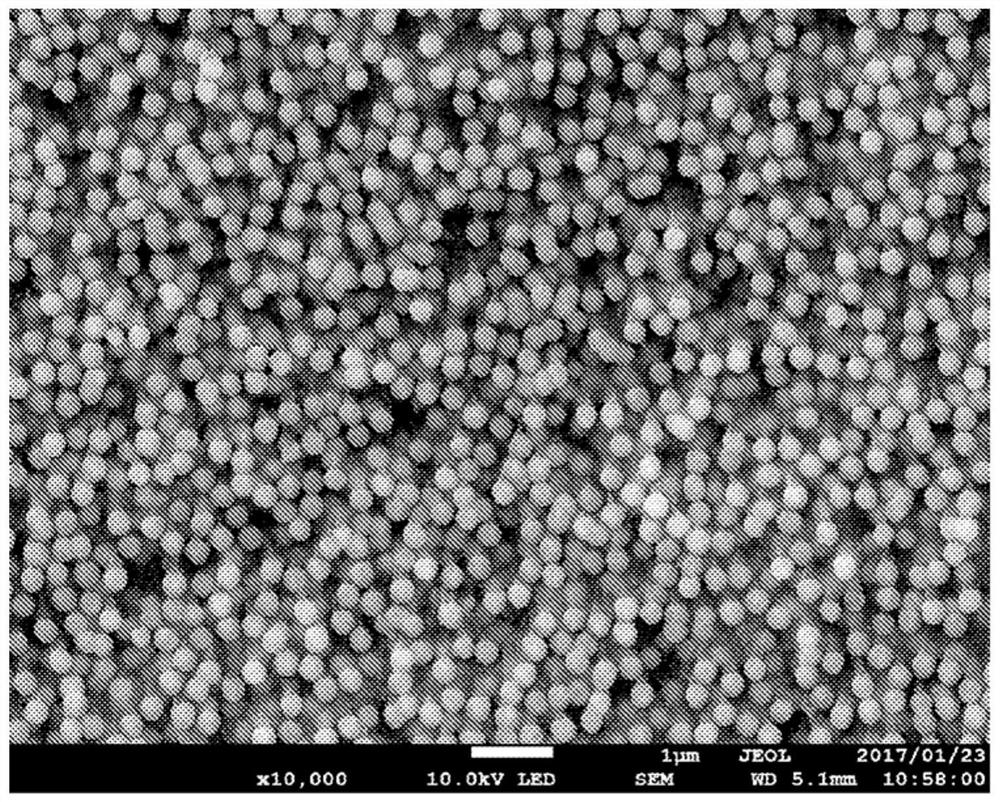

[0241] CQ: 0.3 mass parts, DMBE: 1.0 mass parts, and HQME: 0.15 mass parts were added and mixed with respect to polymerizable monomer mixture M1: 100 mass parts, and the uniform polymerizable monomer composition was prepared. Next, weigh G-PID4: 400 parts by mass and superfine particle group (G-SFP): 0.5 parts by mass, slowly add the above polymerizable monomer composition under red light, and use a mixer planetary mixer (manufactured by Inoue Seisakusho Co., Ltd.) was sufficiently kneaded to obtain a uniform curable paste. Furthermore, this paste was defoamed under reduced pressure to remove air bubbles, and a curable composition was produced. For the cured body (composite material) of the curable composition obtained, (1) evaluation of colored light by visual observation, (2) wavelength measurement of colored light, and (3) evaluation of color tone compatibility by colorimeter were performed , (4) Evaluation of color matching property by visual inspection, and (5) Evaluatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com