A kind of preparation method of bamboo leaf flavone modified fish scale gelatin-chitosan composite film

A technology of fish scale gelatin and bamboo leaf flavonoids is applied in the field of preparation of fish scale gelatin-chitosan composite films modified by bamboo leaf flavonoids, which can solve the problems of undisclosed fish scale gelatin-chitosan composite films modified by bamboo leaf flavonoids, It achieves the effects of superior UV barrier performance, slowing down lipid oxidation and deterioration, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

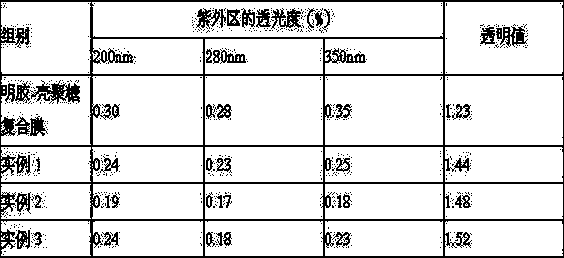

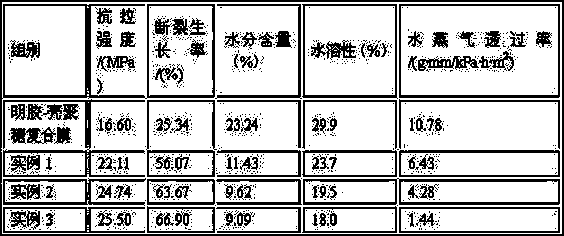

Examples

Embodiment 1

[0027] A kind of preparation method of bamboo leaf flavone modified fish scale gelatin-chitosan composite film, concrete steps are as follows:

[0028] (1) Dissolving chitosan: dissolving chitosan in a glacial acetic acid solution with a concentration of 1 wt%, stirring magnetically for 24 hours overnight to fully dissolve, and then using a 1um pore-diameter filter to remove insoluble matter to obtain a chitosan solution; The mass concentration of chitosan in polysaccharide solution is 1.5%;

[0029] (2) Fish scale gelatin dissolution: Dissolve tilapia scale gelatin in water for 18 minutes after absorbing water and swelling for 18 minutes, then dissolve it in a water bath at 45°C for 22 minutes to obtain a fish scale gelatin solution; the mass concentration of fish scale gelatin in the fish scale gelatin solution is 2% ;

[0030] (3) Adding bamboo leaf flavonoids: adding bamboo leaf flavonoids to the fish scale gelatin solution in an amount of 0.2% of the mass of tilapia scal...

Embodiment 2

[0035] With above-mentioned embodiment 1, its difference is:

[0036] In step (2), the tilapia scale gelatin was dissolved in water for 20 minutes after absorbing water to swell, and then dissolved in a water bath at 50°C for 20 minutes to obtain a fish scale gelatin solution;

[0037] In step (3), bamboo leaf flavonoids are added to the fish scale gelatin solution in an amount of 0.4% of the tilapia scale gelatin mass, and magnetically stirred for 20 minutes to mix evenly to obtain a fish scale gelatin mixture;

[0038] In step (4), mix the chitosan solution and the fish scale gelatin mixture at a volume ratio of 1:1, stir magnetically for 18-22 minutes to mix evenly, add a certain amount of glycerin, and stir magnetically for 15 minutes to mix evenly to obtain a film-forming liquid ;

[0039] In step (5), the film-forming solution is centrifuged and degassed at a speed of 4000 rpm for 5 minutes, and then poured into a glass plate for tape casting; wherein the thickness of t...

Embodiment 3

[0042] With above-mentioned embodiment 1, its difference is:

[0043] In step (2), the tilapia scale gelatin was dissolved in water for 22 minutes and then dissolved in a water bath at 55°C for 18 minutes to obtain a fish scale gelatin solution;

[0044] In step (3), the bamboo leaf flavonoids are added to the fish scale gelatin solution according to the addition amount of 0.6% of the tilapia scale gelatin mass, and magnetically stirred for 22 minutes to mix evenly to obtain a fish scale gelatin mixture;

[0045] In step (4), the chitosan solution and the fish scale gelatin mixture are mixed at a volume ratio of 1:1, and after magnetically stirred for 22 minutes to mix evenly, a certain amount of glycerin is added, and magnetically stirred for 16 minutes to be evenly mixed to obtain a film-forming liquid;

[0046] In step (5), the film-forming solution is centrifuged and degassed at a speed of 4500 rpm for 6 minutes, and then poured into a glass plate for tape casting; wherein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com