EASEMAX yarn-dyed fabric and production method thereof

A production method and fabric technology, applied in the field of textile fabrics, can solve problems not related to spinning, dyeing and finishing, etc., and achieve the effect of improving hand feeling, good elasticity, and excellent hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

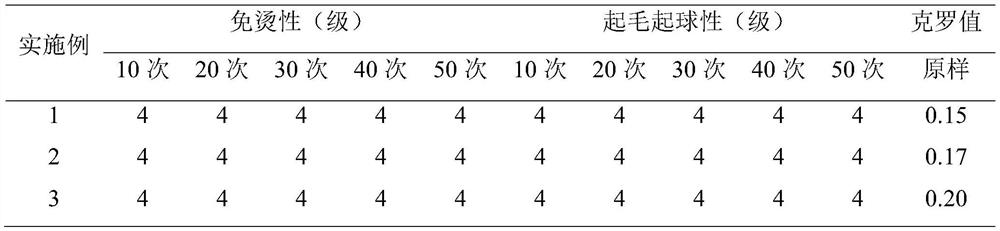

Embodiment 1

[0068] An EASEMAX yarn-dyed fabric is formed by interweaving acrylic fiber, viscose fiber and polyester staple fiber; the weight percentages of acrylic fiber, viscose fiber and polyester staple fiber are respectively: 37% of acrylic fiber, 25% of viscose fiber, Polyester staple fiber 38%.

[0069] The warp yarn is an acrylic / viscose blended yarn made by blending acrylic fiber and viscose fiber by compact spinning, and the yarn count is 40S; the weight percentage of acrylic fiber is 60%, and the weight percentage of viscose fiber is The content is 40%; the wire diameter of the acrylic fiber is 0.9D, and the length is 38mm; the wire diameter of the viscose fiber is 1.0D, and the length is 38mm.

[0070] The weft yarn is made of polyester staple fiber by Siro compact spinning, and the yarn count is 96 / 2S.

[0071] The production method of described EASEMAX yarn-dyed fabric comprises the following steps:

[0073] (1) Alkali reduction pretreatment: a...

Embodiment 2

[0099] An EASEMAX yarn-dyed fabric is formed by interweaving acrylic fiber, viscose fiber and polyester staple fiber; the weight percentages of acrylic fiber, viscose fiber and polyester staple fiber are respectively: 38% of acrylic fiber, 25% of viscose fiber, Polyester staple fiber 37%.

[0100] The warp yarn is an acrylic / viscose blended yarn made by blending acrylic fiber and viscose fiber by compact spinning, and the yarn count is 40S; the weight percentage of acrylic fiber is 60%, and the weight percentage of viscose fiber is The content is 40%; the wire diameter of the acrylic fiber is 0.9D, and the length is 38mm; the wire diameter of the viscose fiber is 1.0D, and the length is 38mm.

[0101] The weft yarn is made of polyester staple fiber by Siro compact spinning, and the yarn count is 96 / 2S.

[0102] The production method of described EASEMAX yarn-dyed fabric comprises the following steps:

[0103] 1. Weft yarn dyeing

[0104] (1) Alkali reduction pretreatment: A...

Embodiment 3

[0130] An EASEMAX yarn-dyed fabric is formed by interweaving acrylic fiber, viscose fiber and polyester staple fiber; the weight percentages of acrylic fiber, viscose fiber and polyester staple fiber are respectively: 41% of acrylic fiber, 27% of viscose fiber, 32% polyester staple fiber.

[0131] The warp yarn is an acrylic / viscose blended yarn made by blending acrylic fiber and viscose fiber by compact spinning, and the yarn count is 40S; the weight percentage of acrylic fiber is 60%, and the weight percentage of viscose fiber is The content is 40%; the wire diameter of the acrylic fiber is 0.9D, and the length is 38mm; the wire diameter of the viscose fiber is 1.0D, and the length is 38mm.

[0132] The weft yarn is made of polyester staple fiber by Siro compact spinning, and the yarn count is 96 / 2S.

[0133] The production method of described EASEMAX yarn-dyed fabric comprises the following steps:

[0134] 1. Weft yarn dyeing

[0135] (1) Alkali reduction pretreatment: a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com