Device and method for deep purification of aluminum-lithium alloy melt

An aluminum-lithium alloy, deep purification technology, applied in the direction of improving process efficiency, can solve problems such as large consumption of argon gas, low purification efficiency, inability to guarantee the metallurgical quality of ingots, etc., and achieve the reduction of maximum inclusion size and oxide content. The effect of reducing and good flaw detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

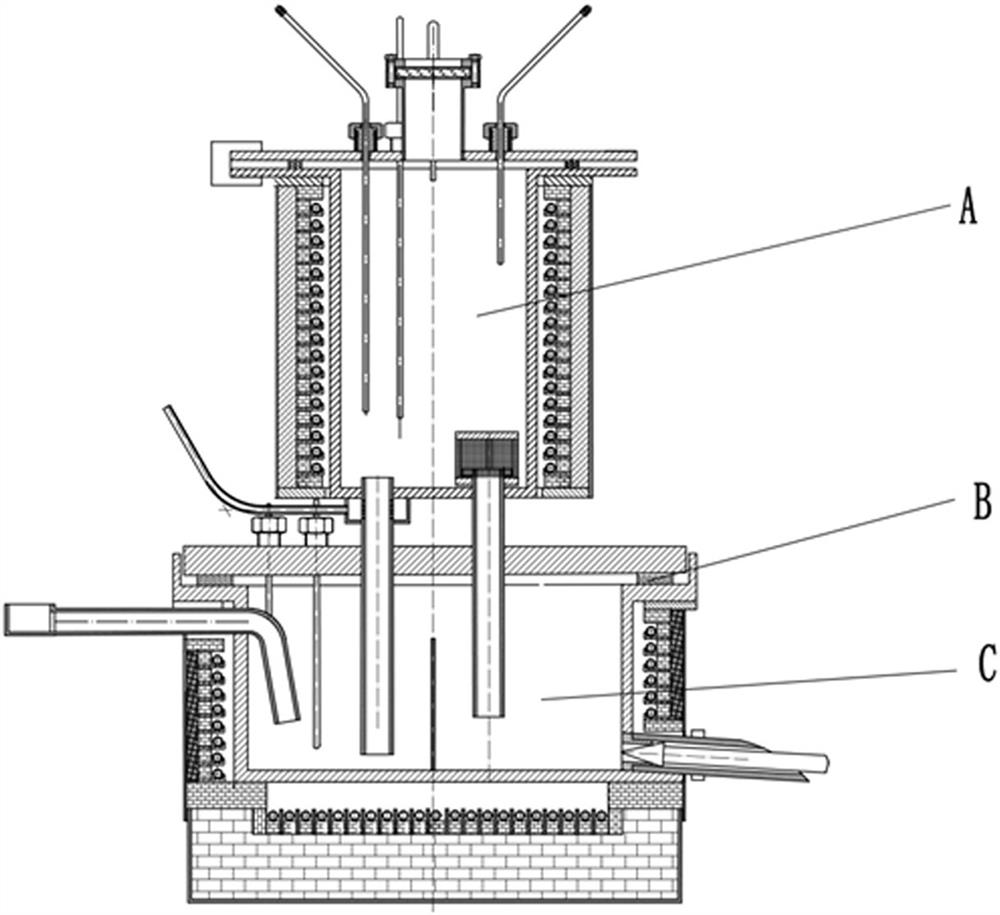

[0073] The structure of the device for deep purification of aluminum-lithium alloy melt is as follows: figure 1 As shown, it consists of purification furnace A, holding furnace gasket B and holding furnace C;

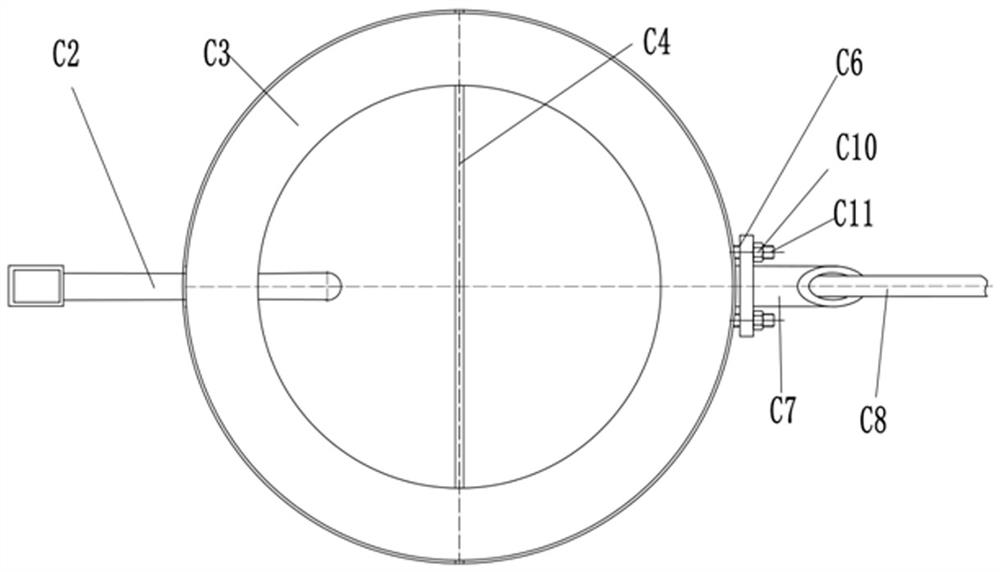

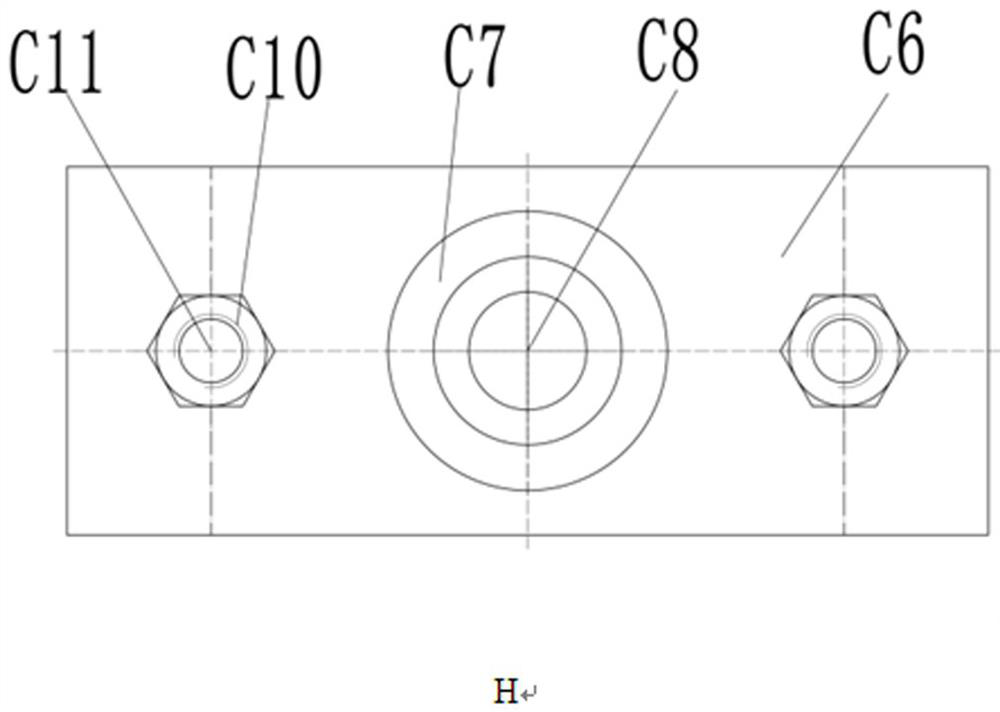

[0074] The structure of purification furnace A is as follows figure 2 As shown, the top view is as image 3 As shown, the A-A direction structure is as follows Figure 4 As shown, it includes the purification furnace crucible A11, the purification furnace body A10, the upper plate A27 and the lower plate A31; the purification furnace body A10 is set outside the side wall of the purification furnace crucible A11, and the top of the purification furnace crucible A11 is sealed and connected with the upper plate A27 , the bottom plate of the purification furnace crucible A11 is provided with a guide tube A1 and a drain tube A33 to connect the bottom plate of the purification furnace crucible A11 up and down, and the guide tube A1 and the discharge tube A33 pass through t...

Embodiment 2

[0103] The structure of the device for the deep purification of the aluminum-lithium alloy melt is the same as in Example 1;

[0104] Method is with embodiment 1, and difference is:

[0105] (1) The processed aluminum-lithium alloy is 2195Al-Li alloy, and its composition is Cu 4.2%, Mg0.43%, Li 1.28%, Zr 0.13%, Ag 0.38%, Fe 0.09%, Si0.04% by mass percentage , the balance is Al;

[0106] (2) When performing deep purification, the temperature when the aluminum-lithium alloy is passed into the holding furnace crucible C3 is 712°C, the temperature released from the outlet C5 is 702°C, and the purification time is 20min; when performing continuous casting, the casting speed is 70mm / min, The ingot diameter is 200mm; the maximum slag inclusion size is 0.9mm, the inclusion area fraction is 0.03%, the ultrasonic flaw detection result is A, and the hydrogen content is 0.08ppm;

[0107] Using the traditional argon-protected continuous casting method in the chute, the aluminum-lithium a...

Embodiment 3

[0110] The structure of the device for the deep purification of the aluminum-lithium alloy melt is the same as in Example 1;

[0111] Method is with embodiment 1, and difference is:

[0112] (1) The processed aluminum-lithium alloy is 1420Al-Li alloy, and its composition is Mg 4.88%, Li2.05%, Zr 0.13%, Fe 0.12%, Si0.11%, and the balance is Al by mass percentage;

[0113] (2) When performing deep purification, the temperature when the aluminum-lithium alloy is passed into the holding furnace crucible C3 is 710°C, the temperature released from the outlet C5 is 697°C, and the purification time is 30min; when performing continuous casting, the casting speed is 50mm / min, The ingot diameter is 300mm; the maximum slag inclusion size is 1.3mm, the inclusion area fraction is 0.08%, the ultrasonic flaw detection result is A, and the hydrogen content is 0.10ppm;

[0114] Using the traditional argon-protected continuous casting method in the chute, the aluminum-lithium alloy of the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com