Device and method for deeply purifying aluminum-lithium alloy melt

An aluminum-lithium alloy, deep purification technology, applied in the direction of improving process efficiency, etc., can solve the problems of low hydrogen removal and slag removal efficiency, low purification efficiency, and ingot metallurgical quality cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

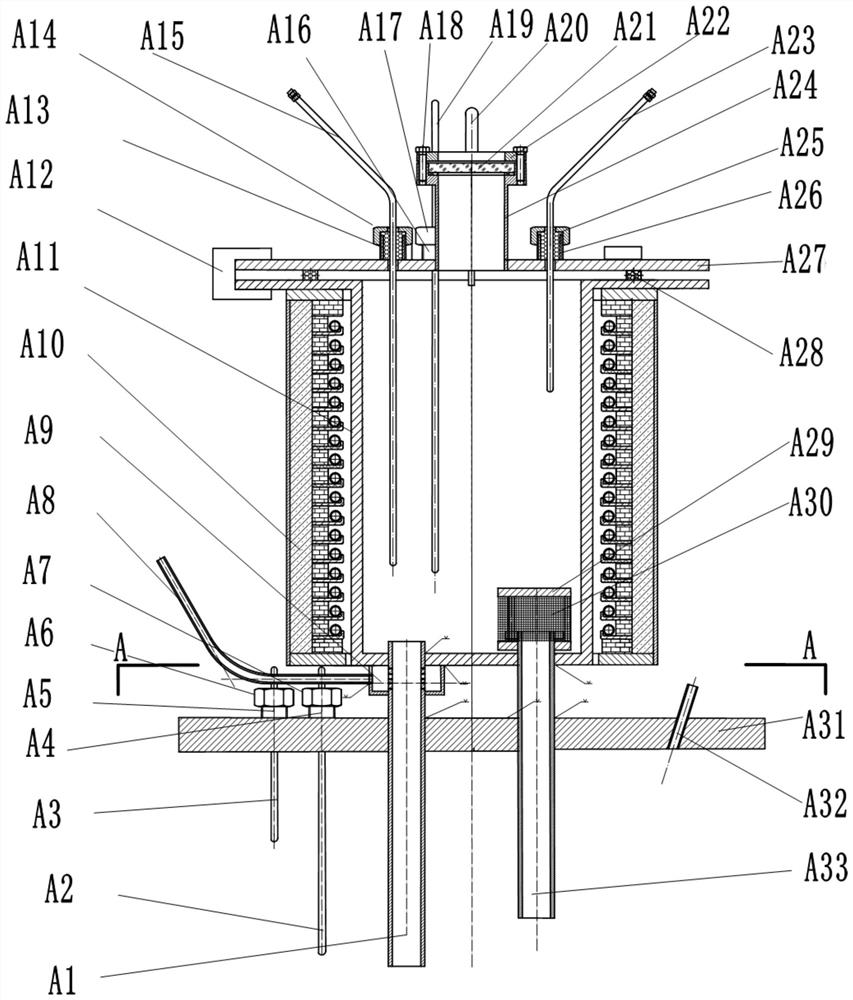

[0073]Device structure of aluminum lithium alloy melt depth purificationfigure 1 As shown, composed of the purge furnace A, the insulation furnace gasket B and the thermal insulating furnace C;

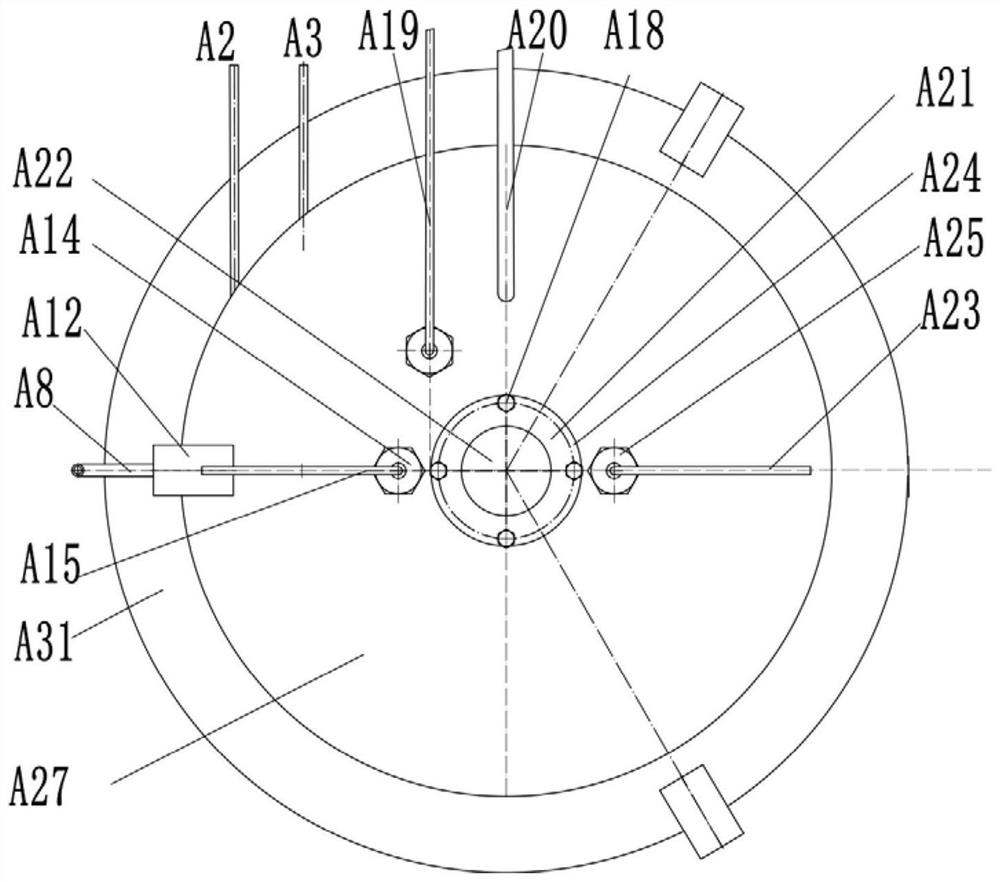

[0074]Purifier A structurefigure 2 As shown, top viewimage 3 As shown, A-A directionFigure 4 As shown, including the purge furnace crucible A11, the purge furnace body A10, the upper plate A27, and the lower plate A31; the purge furnace body A10 is provided outside the sidewall of the purified furnace crucible A11, the top of the purification furnace crucible A11 is sealed with the upper plate A27 sealing connection The bottom plate of the purification furnace crucible A11 is provided with a guide tube A1 and a leakage tube A33 connect the bottom plate of the purge furnace crucible A11, and the drainage tube A1 and the leakage tube A33 pass through the lower plate A31 below the purge furnace. The discharge pipe A33 is provided with a grid A29, and the grid A29 is covered with a web A30; the ar...

Embodiment 2

[0103]Device structure of aluminum lithium alloy melt purification is the same as in Example 1 ,;

[0104]Methods The same embodiments are:

[0105](1) The aluminum alloy treated was 2195Al-Li alloy, and its ingredient was 4.2%, Mg0.43%, Li 1.28%, Zr 0.13%, Ag 0.38%, FE 0.09%, Si0.04%. The margin is Al;

[0106](2) When depth purification, the aluminum lithium alloy passes into the temperature of 712 ° C, from the temperature of 702 ° C from the outflow port C5, purifying time 20 min; when continuous casting, the casting speed is 70 mm / min, The ingot is 200mm in diameter; the maximum degassing size is 0.9 mm, the inclusion area fraction is 0.03%, and the ultrasonic flaw detection is A, the hydrogen content is 0.08 ppm;

[0107]With a conventional chute argon protective continuous casting method, the aluminum lithium alloy of the same material is cast, the maximum scales of the ingot are 3.2mm, the inclosure area fraction is 0.12%, and the ultrasonic flaw is B, hydrogen content 2.6. PPM;

[0108]...

Embodiment 3

[0110]Device structure of aluminum lithium alloy melt purification is the same as in Example 1 ,;

[0111]Methods The same embodiments are:

[0112](1) The above-treated aluminum lithium alloy was 1420Al-Li alloy, and its ingredient was 4.88%, Li2.05%, Zr 0.13%, Fe 0.12%, Si0.11%, and the margin is Al;

[0113](2) When depth purification, the aluminum lithium alloy passes into the temperature of 710 ° C at the temperature of the insulation furnace, from the temperature of 697 ° C from the outflow port C5, purifying time 30 min; when continuous casting, the casting speed is 50 mm / min, The ingot is 300mm in diameter; the maximum degassing size is 1.3mm, the inclusion area fraction is 0.08%, and the ultrasonic flaw detection is a, the hydrogen content is 0.10 ppm;

[0114]With a conventional chute argon protective continuous casting method, the aluminum lithium alloy of the same material is cast, the maximum scales of the ingot are 5.4 mm, the inclusion area fraction is 0.22%, and the ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com