A kind of incinerator automatic slag removal device for preparing 3-aminopropanol

A technology of automatic slag removal and aminopropanol, applied in the direction of incinerator, combustion type, combustion method, etc., can solve the problems of unsanitary, high cost, difficult to manufacture, etc., and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

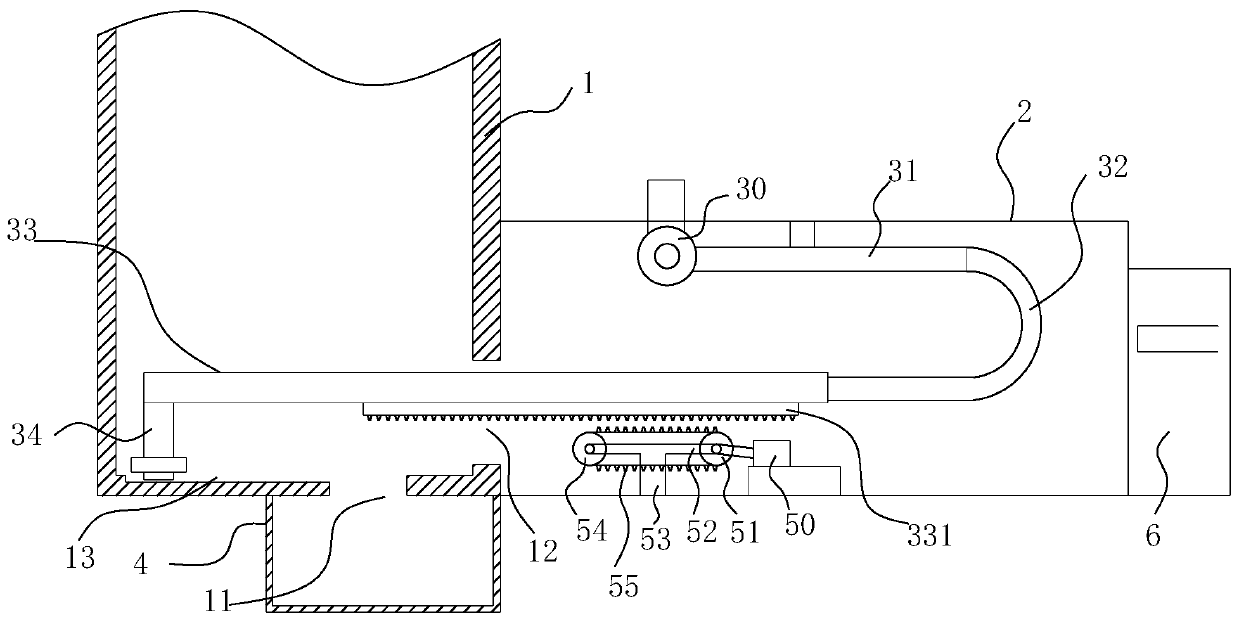

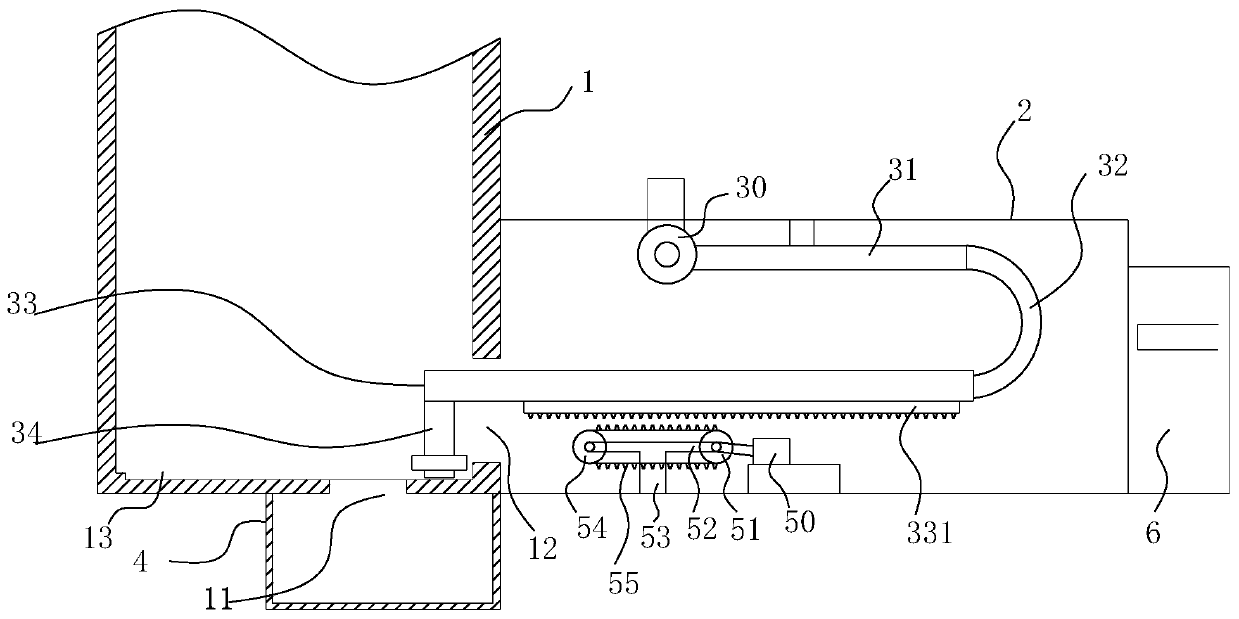

[0023] Such as figure 1 , figure 2 Shown, a kind of incinerator automatic deslagging device for preparing 3-aminopropanol comprises:

[0024] An incinerator 1, the bottom of the incinerator 1 is provided with an ash outlet 11, and the right side wall of the incineration wheel 1 is provided with a through hole 12, and a box body 2 is provided outside the through hole 12;

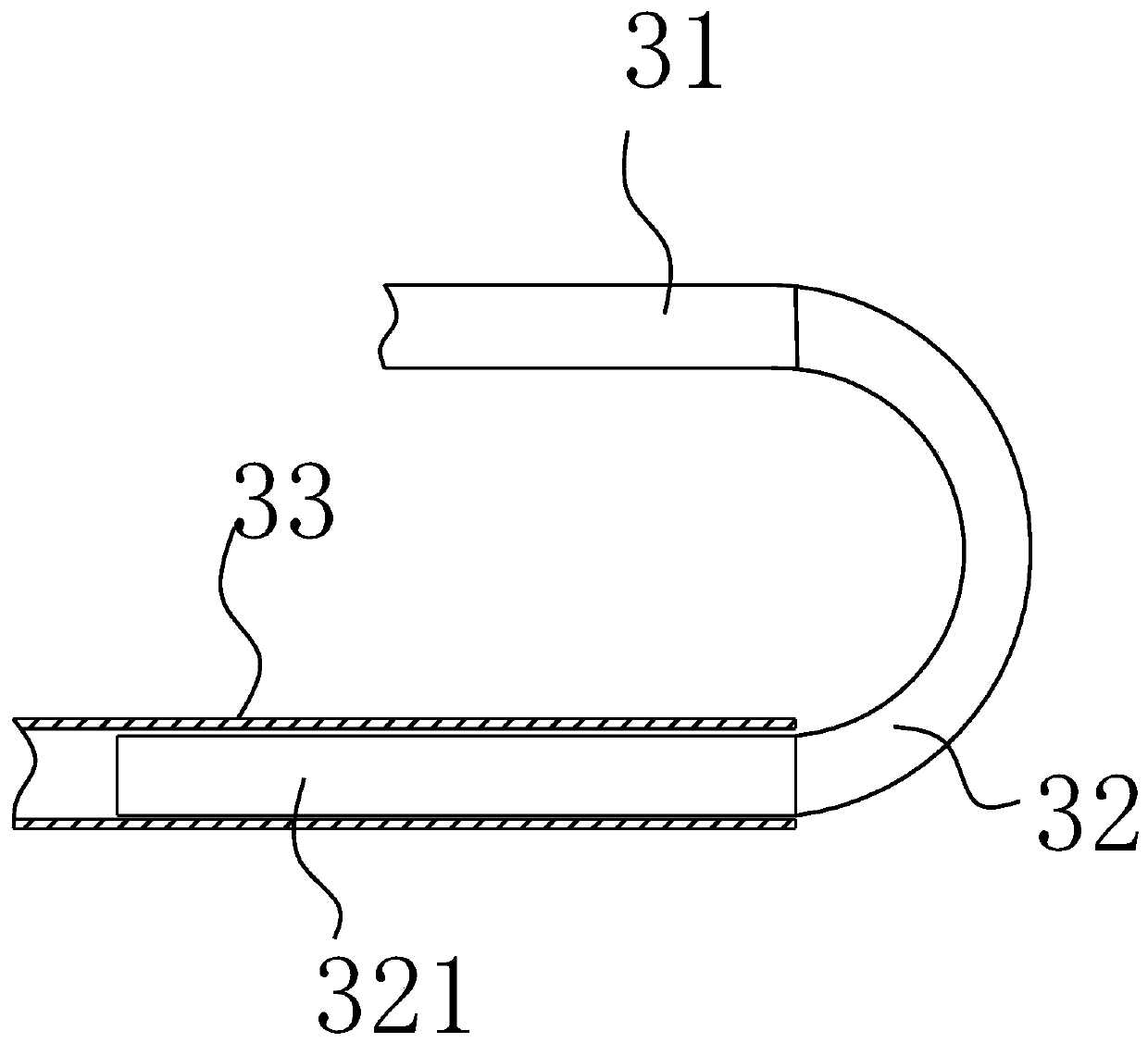

[0025] Such as image 3 , Figure 4 As shown, the slag removal mechanism is arranged in the box body 2, wherein the slag removal mechanism includes a driving device arranged at the bottom of the box body 2, a moving tube 33, and the left end of the moving tube 33 passes through the through hole 12 and extends to In the incinerator 1, a longitudinal pipe 34 is arranged at the left end of the moving pipe 33, a dust scraper 35 is arranged at the bottom of the longitudinal pipe 34, a rack 331 is arranged on the bottom wall of the moving pipe 33, and a fixed pipe is movable inside the right end of the moving p...

Embodiment 2

[0032] Such as figure 1 , figure 2 Shown, a kind of incinerator automatic deslagging device for preparing 3-aminopropanol comprises:

[0033] An incinerator 1, the bottom of the incinerator 1 is provided with an ash outlet 11, and the right side wall of the incineration wheel 1 is provided with a through hole 12, and a box body 2 is provided outside the through hole 12;

[0034] Such as image 3 , Figure 4 As shown, the slag removal mechanism is arranged in the box body 2, wherein the slag removal mechanism includes a driving device arranged at the bottom of the box body 2, a moving tube 33, and the left end of the moving tube 33 passes through the through hole 12 and extends to In the incinerator 1, a longitudinal pipe 34 is arranged at the left end of the moving pipe 33, a dust scraper 35 is arranged at the bottom of the longitudinal pipe 34, a rack 331 is arranged on the bottom wall of the moving pipe 33, and a fixed pipe is movable inside the right end of the moving p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com