Slagging mechanism of electrolytic aluminum liquid slag breaking machine

A technology of electrolytic aluminum liquid and slag machine, applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve the problems of waste of manpower, backward production technology, unfavorable life and health of slag workers, etc., achieve high production efficiency and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

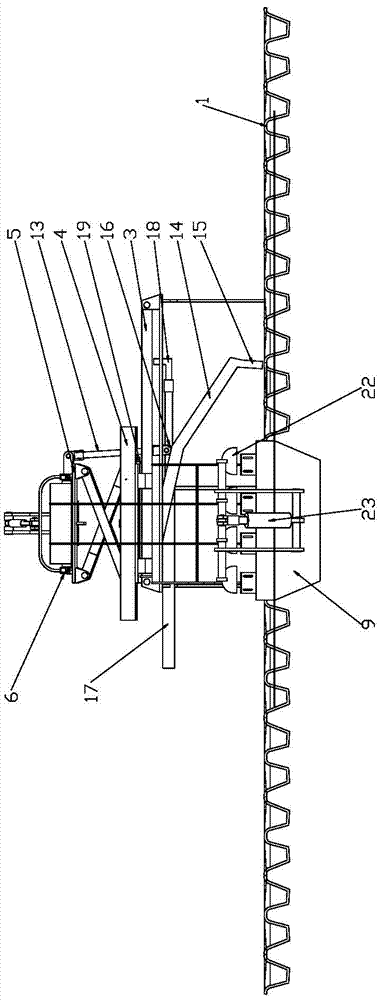

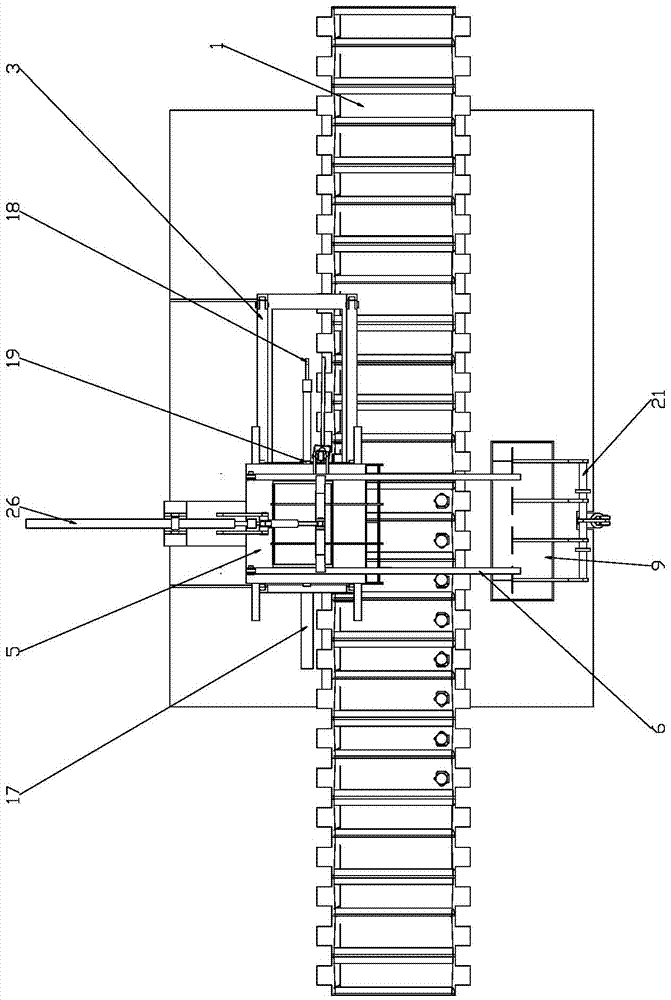

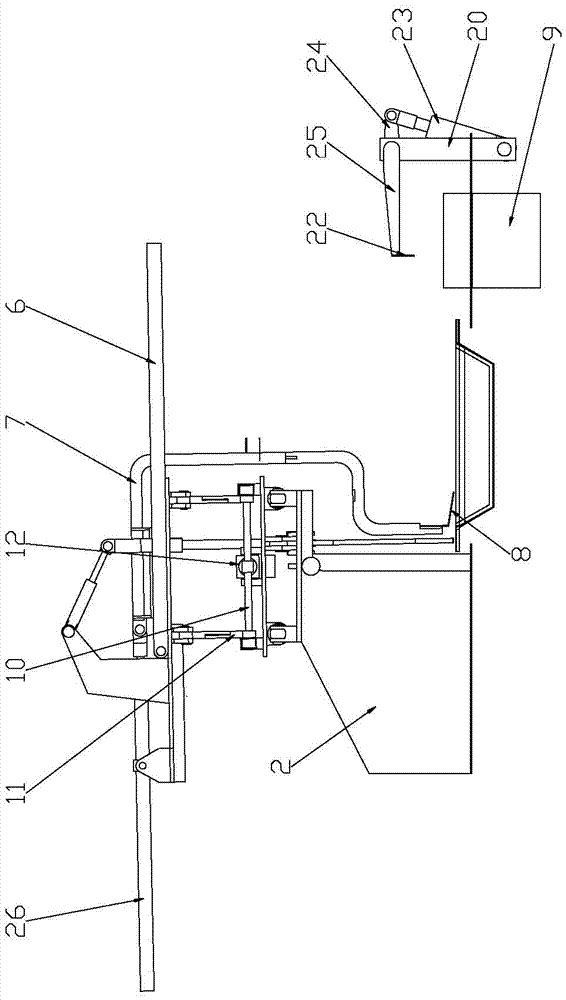

[0023] Such as figure 1 As shown, it is a structural schematic diagram of a slag machine adopting the slag breaking mechanism of the electrolytic aluminum liquid slag machine of the present invention. The slag breaker includes a slag removal mechanism and a slag removal mechanism respectively arranged correspondingly on both sides of the casting mold chain 1 .

[0024] The slagging mechanism of the electrolytic aluminum liquid slag breaking machine in this embodiment includes a fixedly installed mounting frame 2, the mounting frame 2 is provided with a guide rail 3 parallel to the moving direction of the mold chain 1, and a sliding plate 4 is provided on the guide rail 3 to slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com