Large end positioning and clamping device for connecting rod expansion breakage

A technology of positioning and clamping and positioning device, which is applied in workpiece clamping devices, welding equipment, laser welding equipment, etc., can solve problems such as affecting processing efficiency and processing accuracy cannot be effectively guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

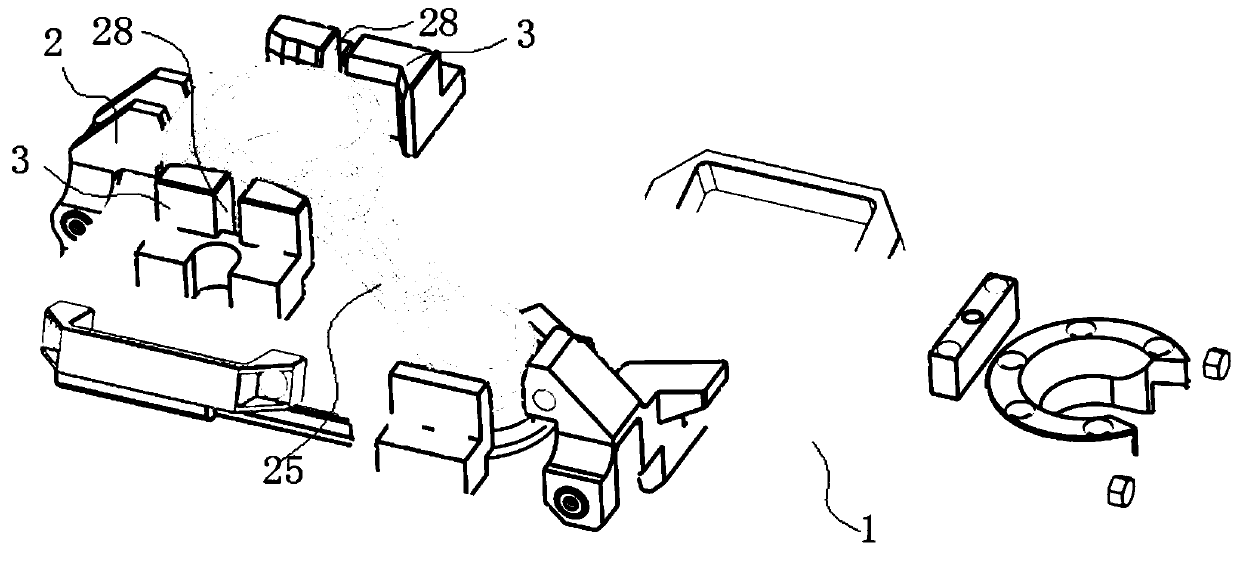

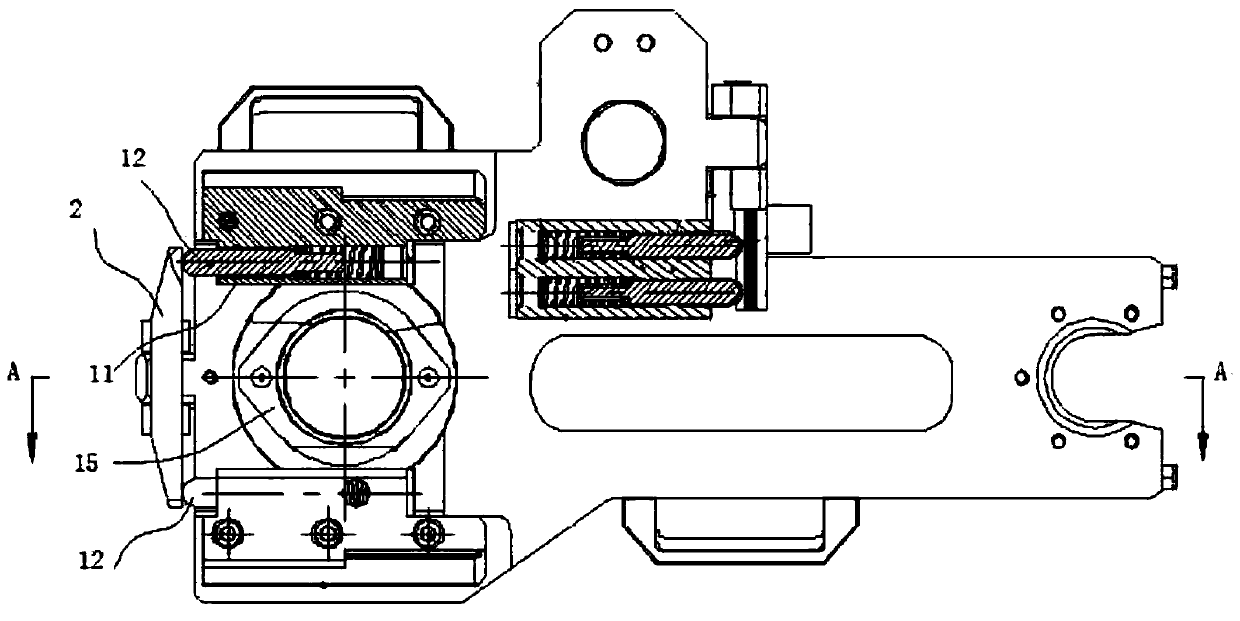

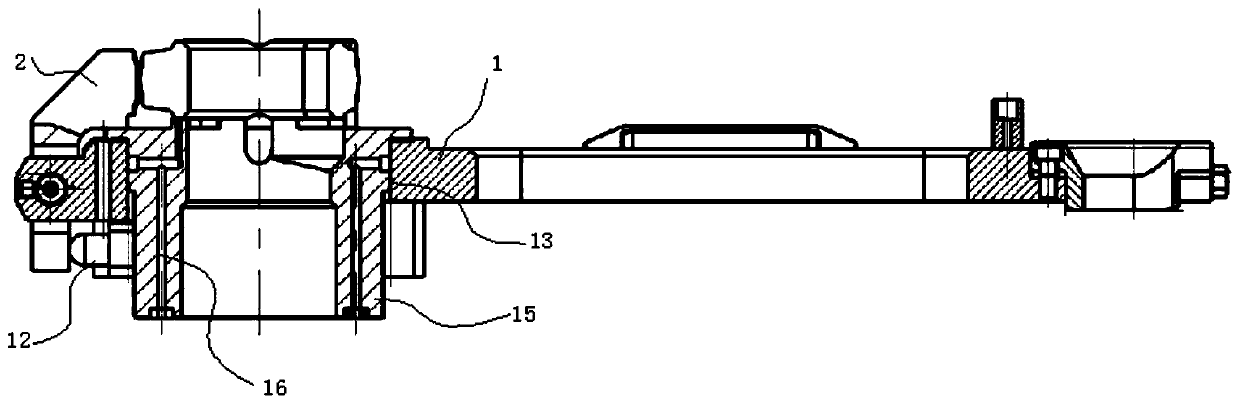

[0015] like Figure 1 to Figure 4 As shown, a connecting rod expansion fixture includes a support plate 1, a large end positioning device and a small end positioning device are arranged on the support plate 1, and the large end positioning device includes a large end movable positioning block 2 and two large end fixed positioning blocks 3. The fixed positioning block 3 of the big head is fixedly installed on the support plate 1 and is perpendicular to the expansion section of the big head. The movable positioning block 2 of the big head is hinged on the support plate 1 and is located between the fixed positioning blocks of the big head Between, the big head movable positioning block 2 and the support plate 1 are provided with a big head elastic pressing mechanism that can make the big head movable positioning block 2 close to the connecting rod, and the big head movable positioning block 2 is parallel to the The swelling section of the big head. When the bolt is assembled, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com