Automatic cleaning and deslagging all-in-one machine

An automatic cleaning and all-in-one machine technology, which is applied in the direction of cleaning devices, conveyor objects, and the use of liquid separation agents, can solve the problems of poor cleaning effect of the belt surface, high pre-tightening friction resistance, and fast wear of the cleaning blade surface, etc., to achieve Avoid the flying of smoke and dust, ensure the quality of slag discharge, and improve the effect of dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

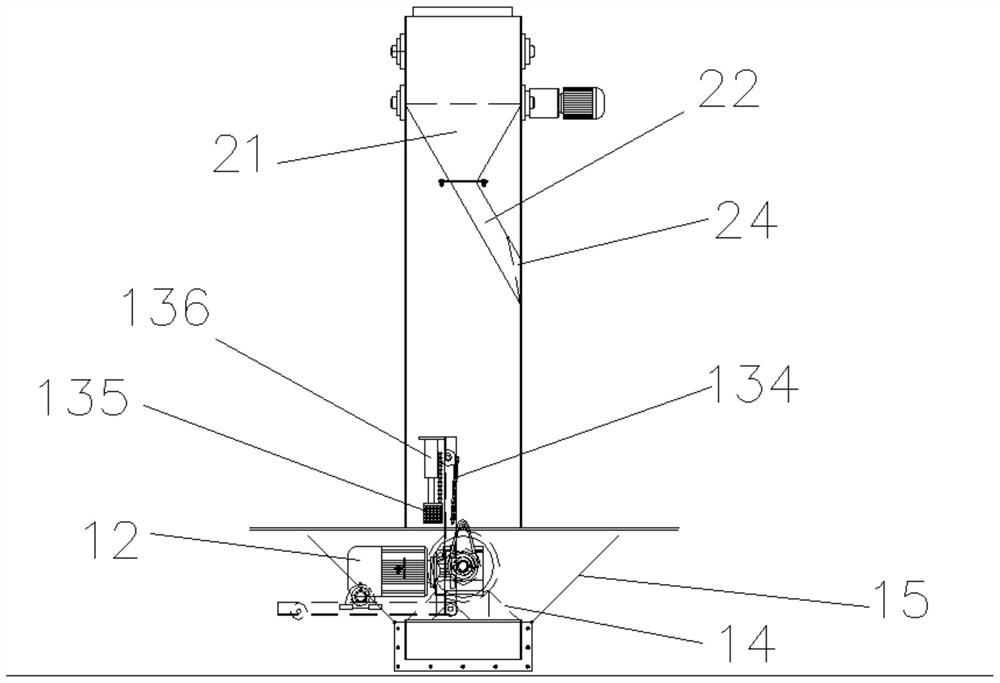

[0027] The invention provides an automatic cleaning and slagging integrated machine, the working principle of which is to realize the connection of the cleaning component and the slagging component through the lifting chain, realize the integration of the slagging process and the cleaning process, and realize the slag removal and cleaning of the belt surface. The purpose of ensuring slag removal efficiency, improving production efficiency and ensuring the personal health of staff.

[0028] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

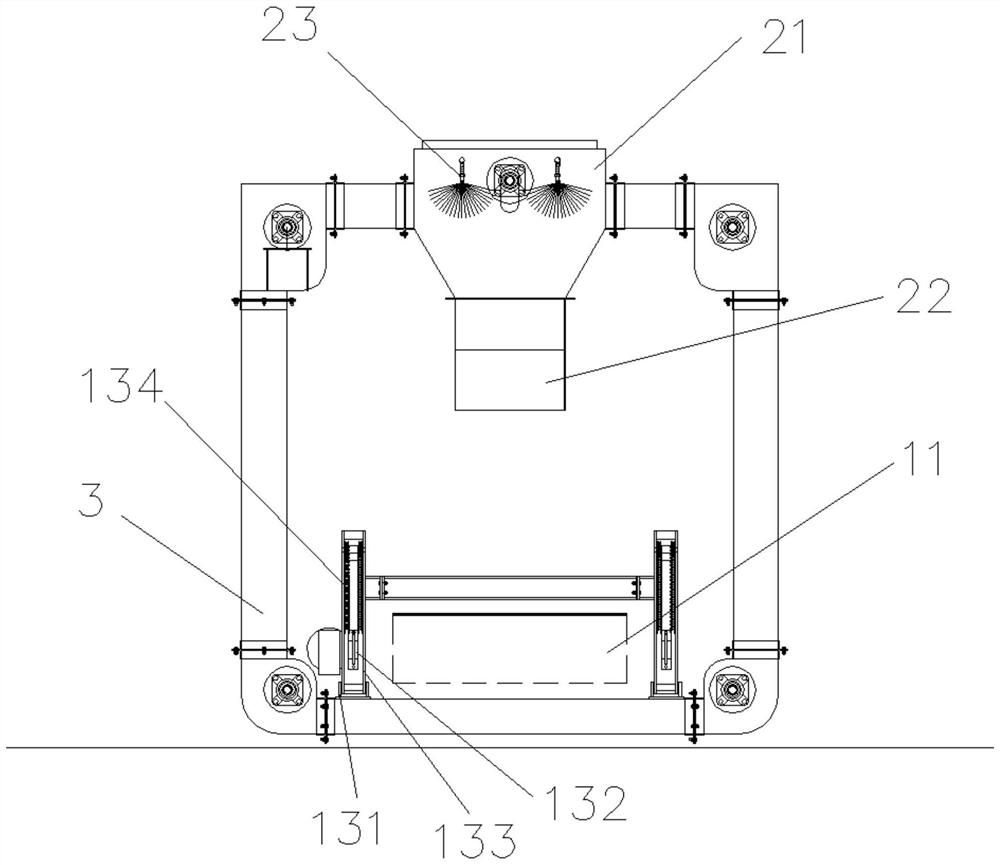

[0029] Such as figure 1 and figure 2 As shown, an automatic cleaning and slag discharge integrated machine includes a cleaning component, a slag discharge co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com