Impurity and dust removal device for front and back surfaces of waste tobacco shreds and impurity and dust removal method thereof

A dust removal device, front and back technology, which is applied in the field of dust removal and dust removal devices on the front and back of waste tobacco shreds, can solve the problems of difficult to guarantee the quality of picking, high labor intensity, affecting the yield of recycled shredded tobacco, etc., and achieve the goal of improving the recycling amount and use value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

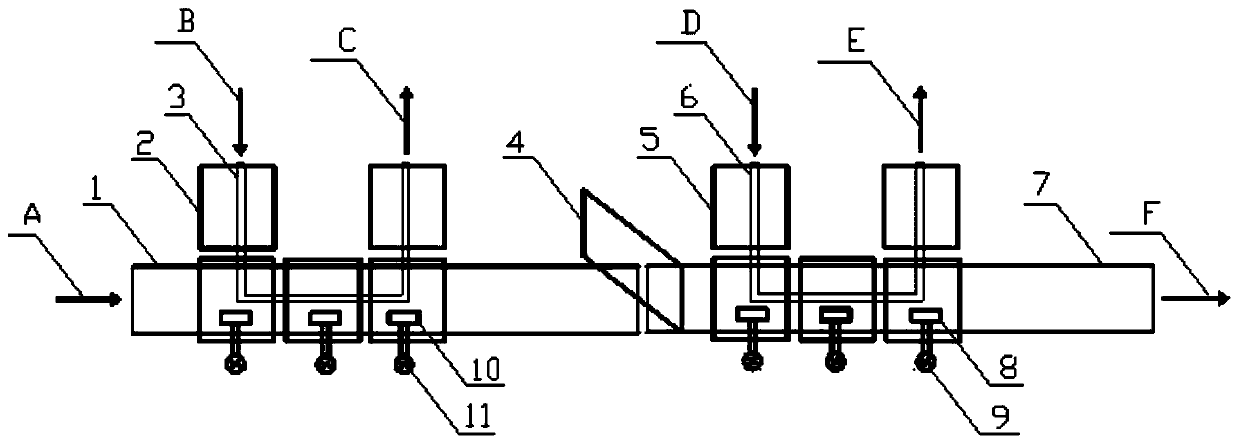

[0057] A device for removing impurities and dust from the front and back sides of waste tobacco shreds, including a front-stage frequency conversion vibration conveying device 1, a rear stage frequency conversion vibration conveying device 7, an electrostatic plate I2, a conveyor belt I3, a baffle plate 4, an electrostatic plate II5, a conveyor belt II6, and electrostatic emission Device I8, Electrostatic Transmitter II10, Electrostatic Transmitter I9 and Electrostatic Transmitter II11;

[0058] The front stage frequency conversion vibration conveying device 1 and the rear stage frequency conversion vibration conveying device 7 are arranged one after the other through the frame, and the vertical height of the front stage frequency conversion vibration conveying device 1 is higher than the vertical height of the rear stage frequency conversion vibration conveying device 7, the described The electrostatic plate I2 and the electrostatic plate II5 are respectively placed on the con...

Embodiment 2

[0066] It is basically the same as that of Example 1, but with the following different features: the conveying speeds of conveyor belt I3 and conveyor belt II6 are both 5m / min; the voltage of electrostatic emitter I8 and electrostatic emitter II10 is 40kV.

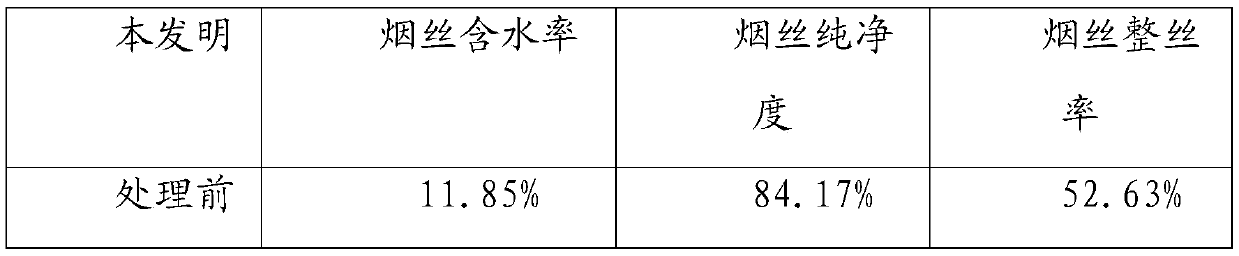

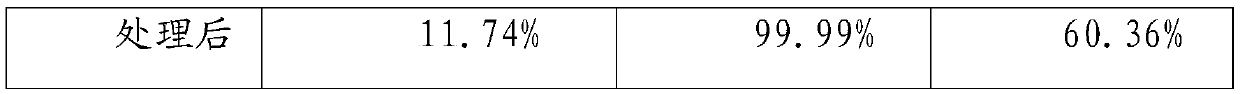

[0067] The subject of the experiment is the waste tobacco processing line of a cigarette production plant. The material flow rate of waste tobacco is 500kg / h. The brand of waste tobacco is Class I slim cigarettes. The processing capacity is 300kg. 12.06%, the whole shredded tobacco is 40.28%, and the purity of shredded tobacco is 72.95%. The requirements for waste tobacco treatment and recovery of shredded tobacco are: the purity of shredded tobacco is ≥99.5%, the whole cut ratio of shredded tobacco is ≥50.00%, and the moisture content of shredded tobacco is 12.0±0.5%. Similarly, the waste smoke shredded tobacco front and back side impurity and dust removal device of the present invention and its removal method are used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com