Dust removal device for steelmaking converter sludge

A technology for a dust removal device and a steelmaking converter, which is applied in the use of liquid separation agents, dispersed particle separation, chemical instruments and methods, etc., can solve the adverse effects of production and environmental protection control, poor dust removal effect, and large dust content in flue gas, etc. To reduce environmental risks and production impacts, reduce dust content, and ensure the quality of dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

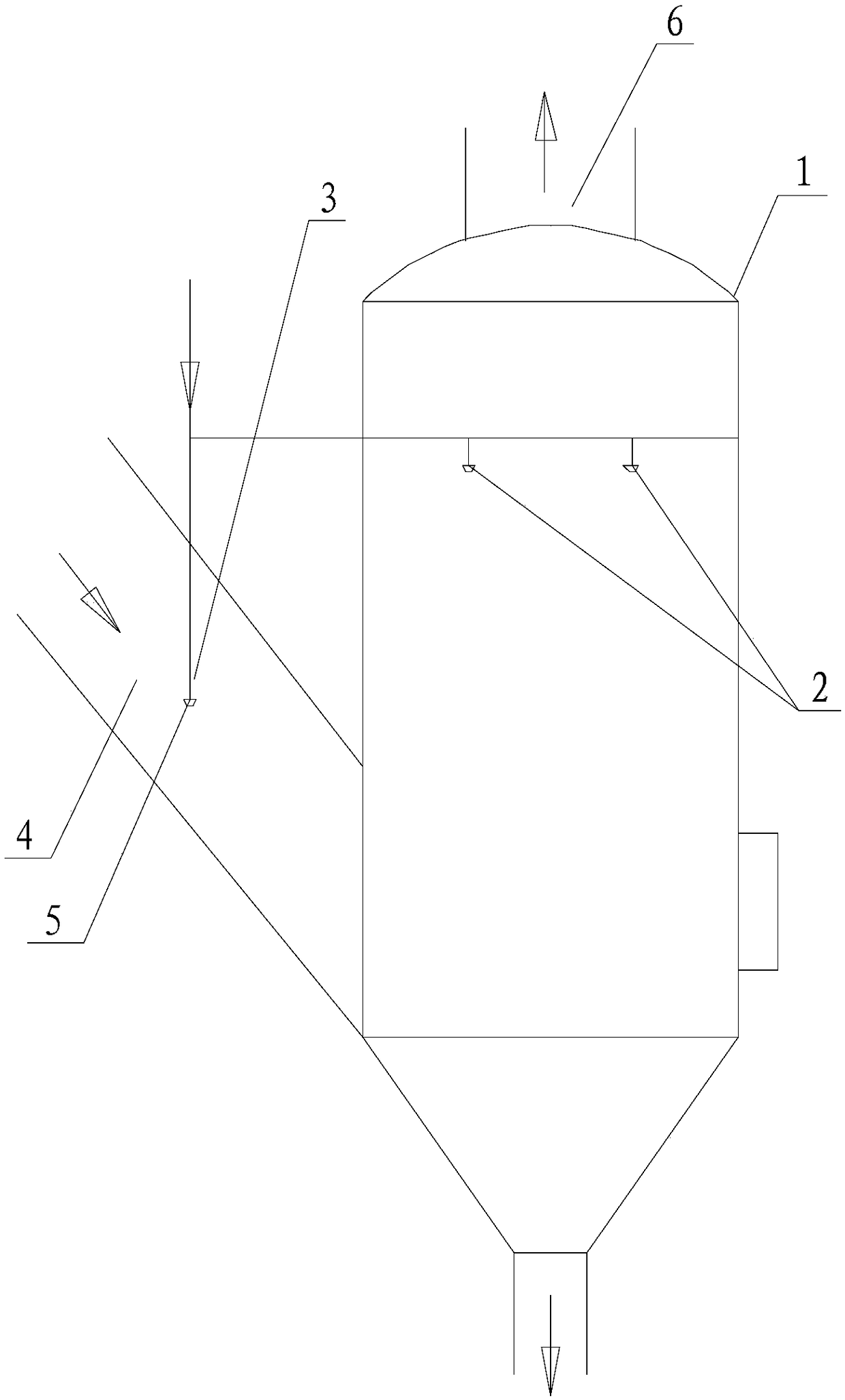

[0016] Such as figure 1 Shown is a dust removal device for steelmaking converter sludge provided by the present invention, which has low operating cost, simple structure, and can reduce environmental risks and production impacts. The dust removal device includes a dust removal tower 1 and a water spray nozzle 2, and the water nozzle 2 is arranged in the middle and upper part of the inner chamber of the dust removal tower with the outlet facing downward, and the dust removal device also includes a pre-dust removal component outside the tower 3. The flue gas that needs to be dedusted before entering the dedusting tower 1 passes through the pre-dust dedusting assembly 3 outside the tower and sprays water for pre-dedusting. In this application, the pre-dust removal component outside the tower is added, and the flue gas that needs to be dedusted before entering the dust removal tower passes through the pre-dust reduction component outside the tower to spray water for pre-dust reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com