In-situ regulation and control method for solid electrolyte interface layer of lithium battery

A solid electrolyte and interface layer technology, which is applied in the manufacture of lithium batteries, non-aqueous electrolyte batteries, and electrolyte batteries, etc., can solve the problems of poor contact between electrodes and solid electrolyte interfaces, poor cycle stability and rate performance of solid lithium ion batteries, and impedance. In order to achieve the effect of enhancing the electron transport ability, inhibiting the growth of lithium dendrites, and reducing the interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

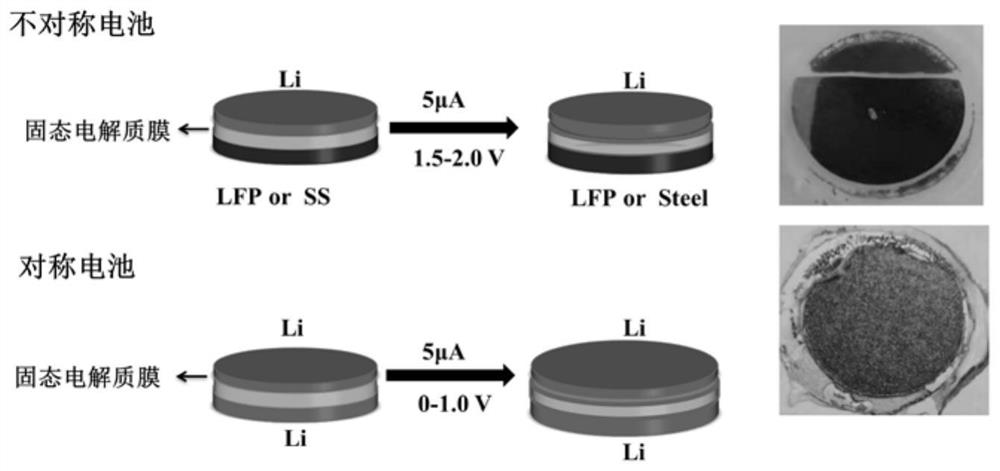

[0028] The method for in-situ regulation of the solid-state electrolyte interface layer of a lithium battery is to prepare a polymer conductive layer in-situ at the interface of the solid-state electrode electrolyte, comprising the following technical steps:

[0029] The mass of organic monomer thiophene, organic polymer PEO, and lithium salt bistrifluoromethanesulfonimide based lithium accounted for 7.7%, 77%, and 15.3% of the mass of the electrolytic membrane, and 1.30 g of the obtained solid electrolyte was dissolved in 20 ml of acetonitrile Among them, the magnetic stirring is dissolved for 18-36h to form a uniform and transparent solution, which is cast in a circular polytetrafluoroethylene mold with a diameter of 90cm, and is dried in a segmented vacuum. Dry at 35-50°C for 23-25 hours; then dry at a pressure of 0.05-0.1Mpa and a temperature of 35-50°C for 23-25 hours to remove the solvent to obtain a solid electrolyte membrane.

[0030] (2) Cut the solid electrolyte ...

Embodiment 2

[0034] The difference from Example 1 is that in Example 2, 2,2`-bithiophene is used as the organic monomer, and the addition amount is consistent with that of thiophene, wherein the content of PEO is 77%, and the content of 2,2`-bithiophene accounts for 7.7% and bistrifluoromethanesulfonimide lithium content accounted for 15.3%, and the rest are the same, and will not be repeated in this embodiment.

Embodiment 3

[0036] The difference from Example 1 is that in Example 3, pyrrole is used as the organic monomer, and the addition amount is doubled compared with Example 1, wherein the content of PEO is 71.4%, the content of 2,2'-dithiophene accounts for 14.3% and The bistrifluoromethanesulfonimide lithium content accounts for 14.3%, and the rest are the same, and assembled into a CR2025 type symmetrical / asymmetrical battery. For the assembled asymmetric battery, place it in the blue battery charging and discharging instrument, set the charging and discharging voltage range 2 to 2.5V and the current as 5μA, and charge and discharge 300 times at a constant current; for the assembled symmetrical battery, on the electrochemical workstation, the voltage is optimal 0 ~ 1.0V and current 5μA, constant current charge and discharge 300 times. The remaining steps are the same as those in Embodiment 1, and will not be repeated in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com