High-dispersity high-concentration nylon-based halogen-free flame-retardant master batch and preparation method thereof

A flame-retardant masterbatch, high-concentration technology, applied in the field of polymer material preparation, can solve the problems of difficult processing, rough surface, poor fluidity, etc., and achieve the effects of good dispersion, smooth surface and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing a high-concentration and highly dispersible nylon-based halogen-free flame-retardant masterbatch, which includes the following steps:

[0035] Step S1: Provide a nylon resin carrier, an organic hypophosphite, and a melamine derivative, wherein the mass percent content of the nylon resin carrier is 20% to 45%, and the mass percent content of the organic hypophosphite is 25% to 60% , the mass percent content of the melamine derivative is 15% to 40%;

[0036] Step S2: compound the organic hypophosphite and melamine derivatives in proportion to form a halogen-free flame retardant, and fully mix them in a mixing device;

[0037] Step S3: providing a lubricating dispersant and an anti-yellowing agent, the mass percentage content of the lubricating dispersant is 1%-5%, and the mass percentage content of the anti-yellowing agent is 0.5%-3%;

[0038] Step S4: Premix the granulated nylon resin carrier, lubricating disper...

Embodiment A1-A8 and comparative example 1-3

[0057] Examples A1-A8 and Comparative Examples 1-3 were prepared according to the mass ratio of each component in Table 1, and according to the following processing and preparation methods to prepare nylon-based halogen-free flame-retardant masterbatches. The preparation method is as follows:

[0058] (1) compound organic hypophosphite and melamine derivatives or metal oxides in proportion to form a halogen-free flame retardant, and fully mix them in a mixing device;

[0059] (2) Premix nylon carrier particles, lubricating dispersant, and anti-yellowing agent in a mixer in proportion, then add halogen-free flame retardant and mix evenly;

[0060] (3) Add the nylon premix into a twin-screw extruder, melt and blend, and extrude to obtain a halogen-free flame-retardant masterbatch.

[0061] Table 1 Formula and processing performance of nylon carrier flame retardant masterbatch

[0062]

[0063]

[0064] From the comparison of flame retardant masterbatch processing and perf...

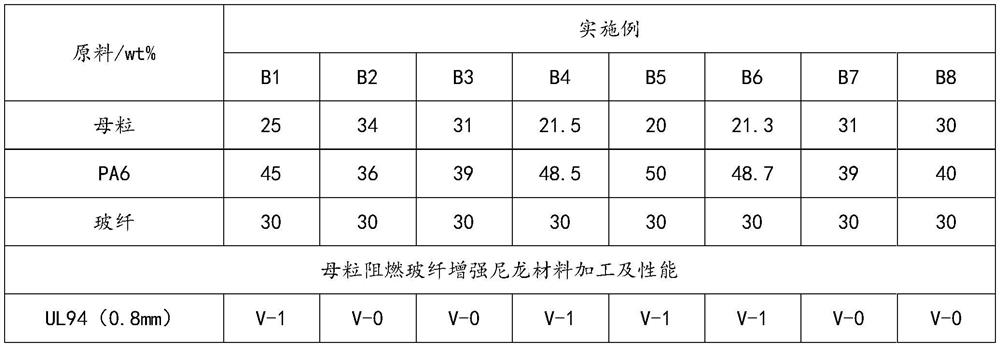

Embodiment B1-B8

[0066] Add the nylon-based flame-retardant masterbatches with different concentrations of flame retardants processed in the above-mentioned examples A1-A8 to the glass fiber reinforced PA6 system to obtain flame-retardant glass fiber-reinforced nylon materials B1-B8, and the masterbatches in each embodiment , Nylon resin and glass fiber consumption and performance tests are listed in Table 2.

[0067] Table 2 Masterbatch Flame Retardant Glass Fiber Reinforced PA6 Material Formula and Properties

[0068]

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com