Water-based high-filling white paint

A water-based, coating technology, applied in the direction of filling slurry, coating, etc., can solve the problems of unsafe, harmful to the construction personnel, not environmentally friendly, etc., and achieve the effect of good sealing, convenient construction, and good polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Composition:

[0033] The parts by weight of each raw material in the embodiment 1 of table 1

[0034] Element Weight (kg) Deionized water 152 BIT-20 (BIT, preservative) 3 DPM (dipropylene glycol methyl ether, coalescent) 30 Airex902W (water-based polysiloxane solution, water-based defoamer) 5 BYK190 (water-based wetting and dispersing additive) 8 R-996 (titanium dioxide) 100 CC-1500 ultrafine calcite powder (CaCO3, filler) 100 CC-800 ultrafine calcite powder (CaCO3, filler) 220 MS-1250 (talc powder) 145 ammonia 2 TT-935 (alkali-swellable acrylic acid copolymer solution, water-based thickener) 1 Deionized water 8 CONCRYL1915 (water-based acrylic resin, solid content is 44%) 220 RW-12W (non-ionic water-based polyurethane, water-based thickener) 3 TT935 (alkali-swellable acrylic acid copolymer solution, water-based thickener) 4 BYK028 (polyethylene glycol-hydrophobic...

Embodiment 2

[0046] 1. Composition:

[0047] The parts by weight of each raw material in the embodiment 2 of table 2

[0048] Element Weight (kg) Deionized water 152 BIT-20 (BIT, preservative) 3 DPM (dipropylene glycol methyl ether, coalescent) 30 Airex902W (water-based polysiloxane solution, water-based defoamer) 5 BYK190 (water-based wetting and dispersing additive) 8 R-996 (titanium dioxide) 100 CC-1500 ultrafine calcite powder (CaCO3, filler) 100 CC-800 ultrafine calcite powder (CaCO3, filler) 220 Wollastonite Powder 1250 (Wollastonite) 145

[0049] ammonia 2 TT-935 (alkali-swellable acrylic acid copolymer solution, water-based thickener) 1 Deionized water 8 CONCRYL1915 (water-based acrylic resin, solid content is 44%) 220 RW-12W (non-ionic water-based polyurethane, water-based thickener) 3 TT935 (alkali-swellable acrylic acid copolymer solution, water-based thickener) 4 BY...

Embodiment 3

[0061] 1. Composition:

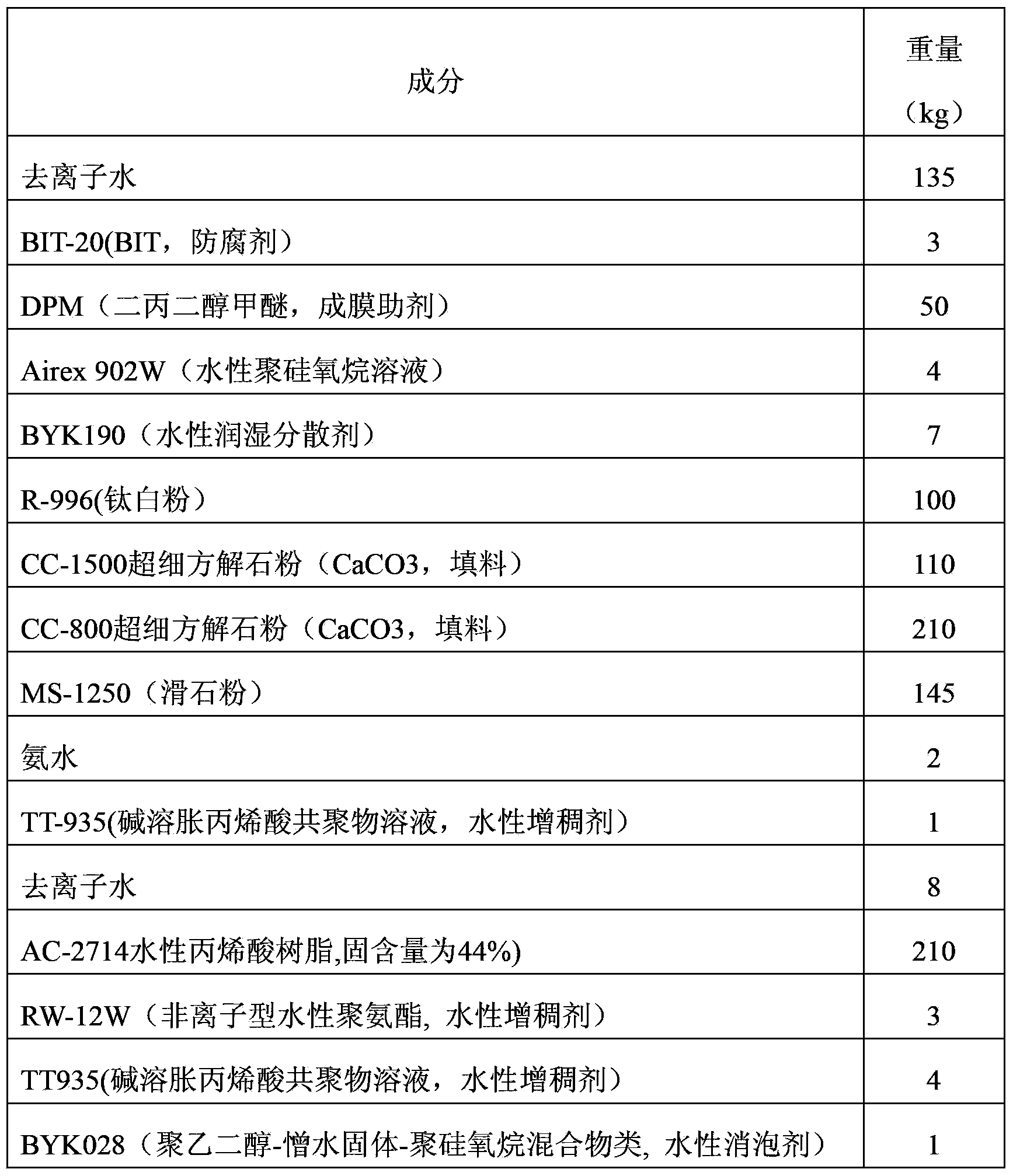

[0062] The parts by weight of each raw material in table 3 embodiment 3

[0063] Element Weight (kg) Deionized water 132 BIT-20 (BIT, preservative) 3 DPM ((dipropylene glycol methyl ether, coalescent) 50 Airex902W (water-based polysiloxane solution, water-based defoamer) 4 BYK190 (water-based wetting and dispersing additive) 7 R-996 (titanium dioxide) 100 CC-1500 ultrafine calcite powder (CaCO3, filler) 110 CC-800 ultrafine calcite powder (CaCO3, filler) 210 MS-1250 (talc powder) 145 ammonia 2 TT-935 (alkali-swellable acrylic acid copolymer solution, water-based thickener) 1 Deionized water 8 A-639 (water-based acrylic resin, solid content is 45%) 210 RW-12W (non-ionic water-based polyurethane, water-based thickener) 3 TT935 (alkali-swellable acrylic acid copolymer solution, water-based thickener) 4

[0064] BYK028 (polyethylene glycol-hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com