Wafer slicing machine

A slicing machine and wafer technology, which is applied in the field of wafer slicing machines, can solve the problems of affecting the dicing quality of wafers, the collapsed edge of the wafer being heated and rolling up, and the frictional heat being difficult to dissipate quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

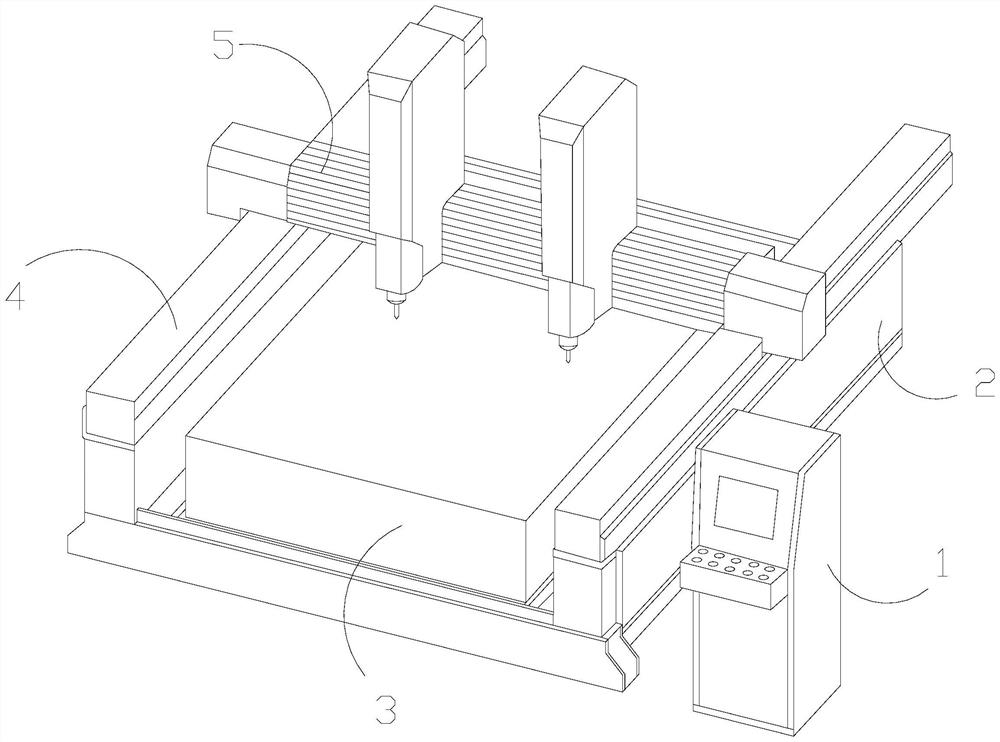

[0029] as attached figure 1 to attach Figure 6 Shown:

[0030] The invention provides a wafer slicing machine, the structure of which is provided with a console 1, a support base 2, a placement table 3, a side rail 4, and a working body 5, the console 1 is installed on the side end of the support base 2, and the The placement platform 3 is located at the interval section of the support seat 2, the side rail 4 and the support seat 2 are integrated structures and are arranged at both sides thereof, and the operating body 5 moves on the top surface end of the placement platform 3, so The two ends of the working body 5 are slidingly matched with the side rails 4 .

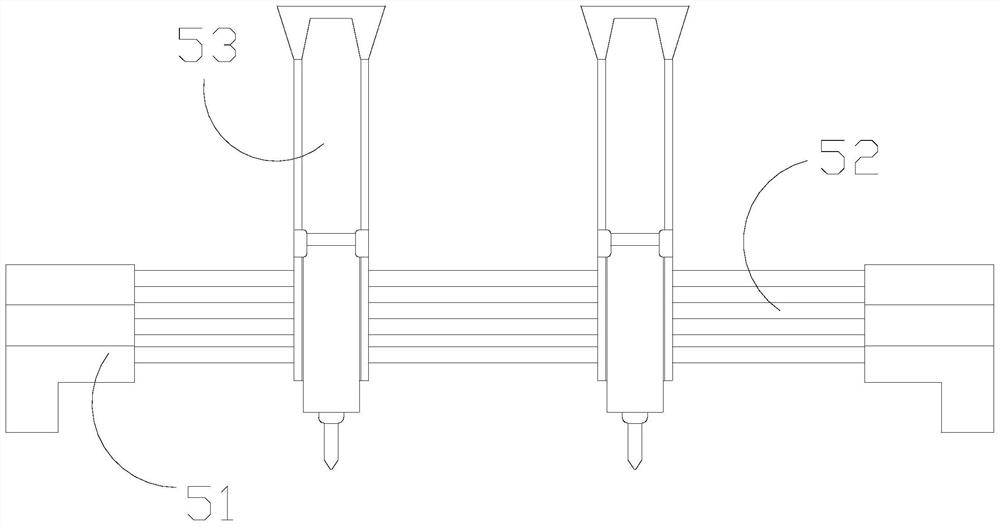

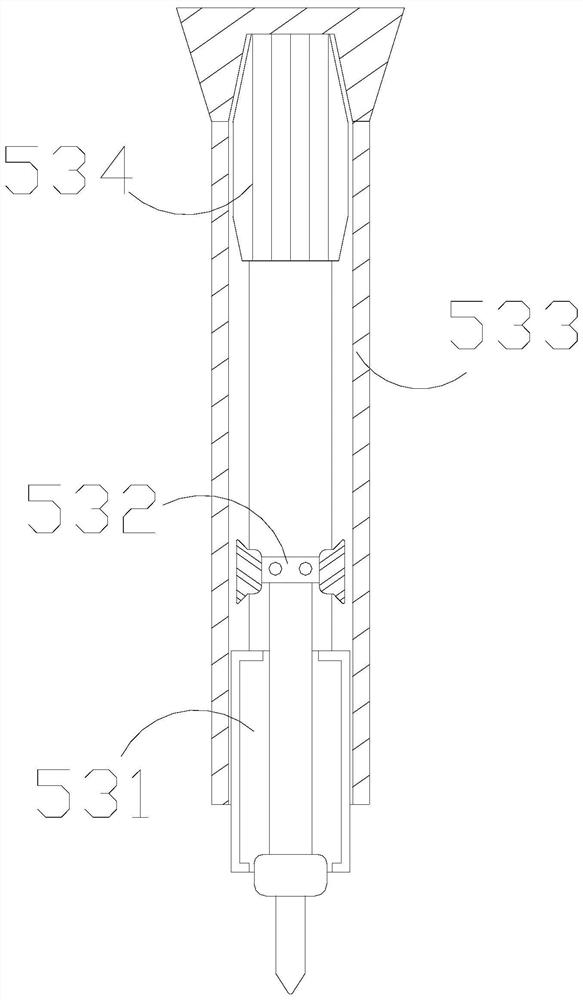

[0031] The working body 5 is provided with a buckle sliding end 51, a middle slide rail 52, and a cutting device 53. The buckle slide end 51 is embedded and connected to both ends of the middle slide rail 52, and the cutting device 53 is fastened and connected to the middle slide rail. 52 on and slip fit.

[0032]...

Embodiment 2

[0038] as attached Figure 7 To attach Figure 8 Shown:

[0039] Wherein, the scribing knife a4 is provided with a blade a41 and a circumferential groove a42, the circumferential groove a42 and the knife edge a41 are of an integrated structure and are arranged at its peripheral position, and the circumferential groove a42 is a groove on the blade a41. Groove cavity, which increases the contact area with the air, is the dredging surface for the increase of heat gas.

[0040] Wherein, the circumferential groove a42 is provided with a groove inner surface b1, a rotating block b2, and a spring b3. The loose blocks b2 are connected and movably matched. The scattered block b2 is embedded and movable on the front side of the inner surface b1 of the groove. The scattered block b2 is cross-shaped, and the elastic force of the spring b3 drives the scattered block b2 to swing back and forth. , so that the flow rate of the airflow can be changed to facilitate the flow of heat gas.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com