Titanium dioxide plus carbon boiling chlorination simulation reactor and simulation method

A technology of titanium dioxide and boiling chlorination, applied in chemical instruments and methods, titanium halide, titanium tetrachloride, etc., can solve problems such as failure to study well, failure to effectively reveal the law of complex interaction effects, etc. Accuracy, improving universality, and improving experimental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

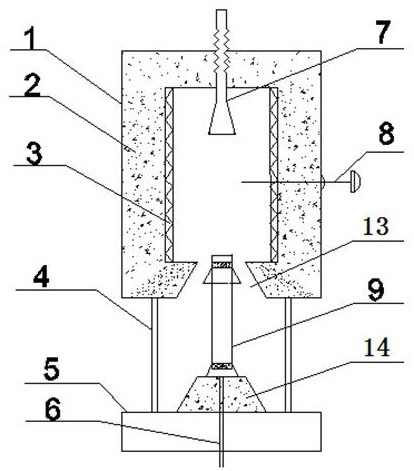

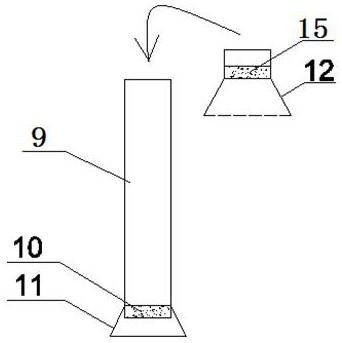

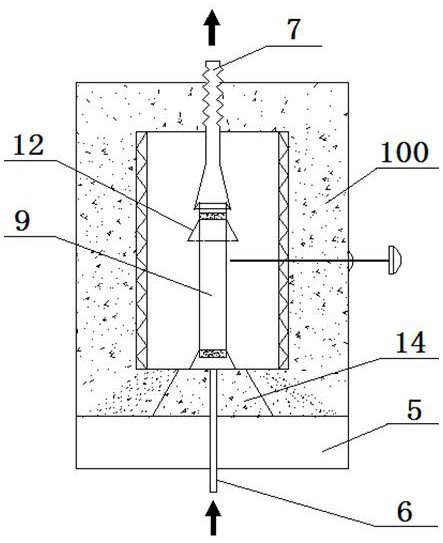

[0056] TiO with a particle size of 200-300 mesh and a purity of 99% 2 Particles and petroleum coke particles with a particle size of 120-160 mesh and a C content of 99% are evenly placed in the quartz tube 9, and the quartz tube 9 is sent into the heating furnace 100 through the telescopic rod 4, and the height of the exhaust pipe 7 is adjusted so that The top of the top cover 12 is connected and sealed with the exhaust pipe 7 . Adjust the temperature of the furnace to 900°C. During the heating stage, the nitrogen gas source is introduced into the inlet channel 6, and the superficial gas velocity is adjusted to be 0.15m / s, so that the mixture in the quartz tube 9 is boiled and fluidized. When the temperature rose to 900°C, the nitrogen gas was switched to chlorine gas, the gas velocity was kept constant, and the reaction time was 30 minutes. TiCl produced by the reaction 4 , CO, CO 2 In the form of gas, it is discharged into the alkali solution from the exhaust pipe 7 for a...

Embodiment 2

[0058] TiO with a particle size of 200-300 mesh and a purity of 99% 2 Particles and petroleum coke particles with a particle size of 120-160 mesh and a C content of 99% are evenly placed in the quartz tube 9, and the quartz tube 9 is sent into the heating furnace 100 through the telescopic rod 4, and the height of the exhaust pipe 7 is adjusted so that The top of the top cover 12 is connected and sealed with the exhaust pipe 7 . Adjust the furnace temperature to 900°C. During the heating stage, the nitrogen gas source is introduced into the inlet channel 6, and the superficial gas velocity is adjusted to be 0.20m / s, so that the mixture in the quartz tube 9 is boiled and fluidized. When the temperature rose to 900°C, the nitrogen gas was switched to chlorine gas, the gas velocity was kept constant, and the reaction time was 30 minutes. TiCl produced by the reaction 4 , CO, CO 2 In the form of gas, it is discharged into the alkali solution from the exhaust pipe 7 for absorpti...

Embodiment 3

[0060] TiO with a particle size of 200-300 mesh and a purity of 99% 2 Particles and petroleum coke particles with a particle size of 120-160 mesh and a C content of 99% are evenly placed in the quartz tube 9, and the quartz tube 9 is sent into the heating furnace 100 through the telescopic rod 4, and the height of the exhaust pipe 7 is adjusted so that The top of the top cover 12 is connected and sealed with the exhaust pipe 7 . Adjust the furnace temperature to 900°C. During the heating stage, the nitrogen gas source is introduced into the inlet channel 6, and the superficial gas velocity is adjusted to be 0.25m / s, so that the mixture in the quartz tube 9 is boiled and fluidized. When the temperature rose to 900°C, the nitrogen gas was switched to chlorine gas, the gas velocity was kept constant, and the reaction time was 30 minutes. TiCl produced by the reaction 4 , CO, CO 2 In the form of gas, it is discharged into the alkali solution from the exhaust pipe 7 for absorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com