High-stability vibration absorber

A high-stability, vibration absorber technology, applied in the functional characteristics of spring/shock absorber, inertial force compensation, spring/shock absorber, etc., can solve the problems of vibration absorber sensitivity, reduce the workload of frequency modulation, a large amount of manpower and time, etc. , to achieve the effect of reducing the size of the structure, reducing the workload of frequency modulation, and fast frequency modulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

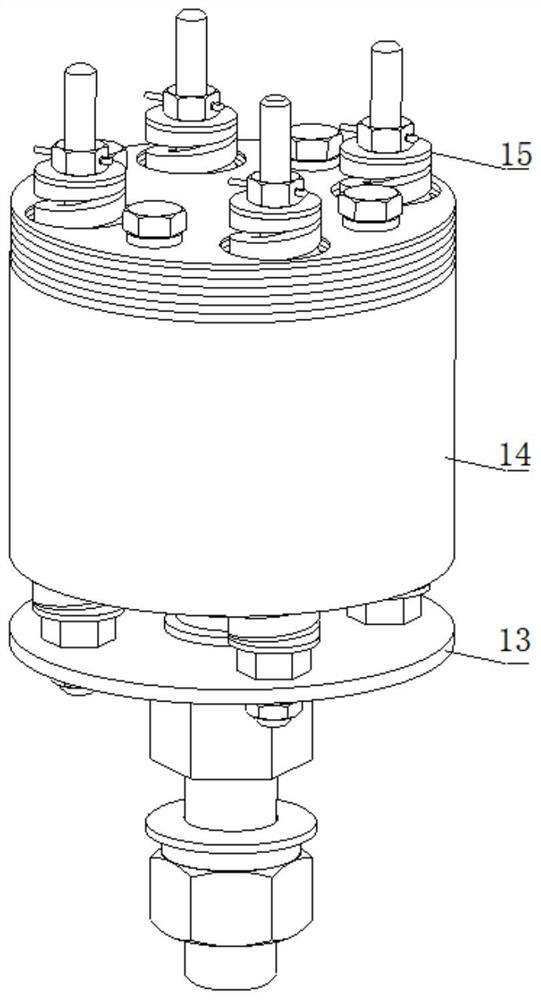

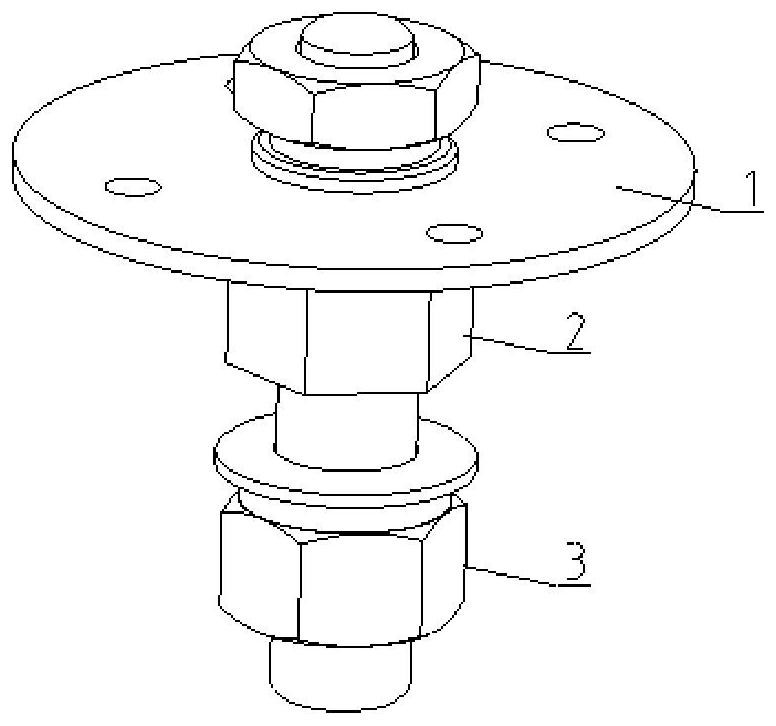

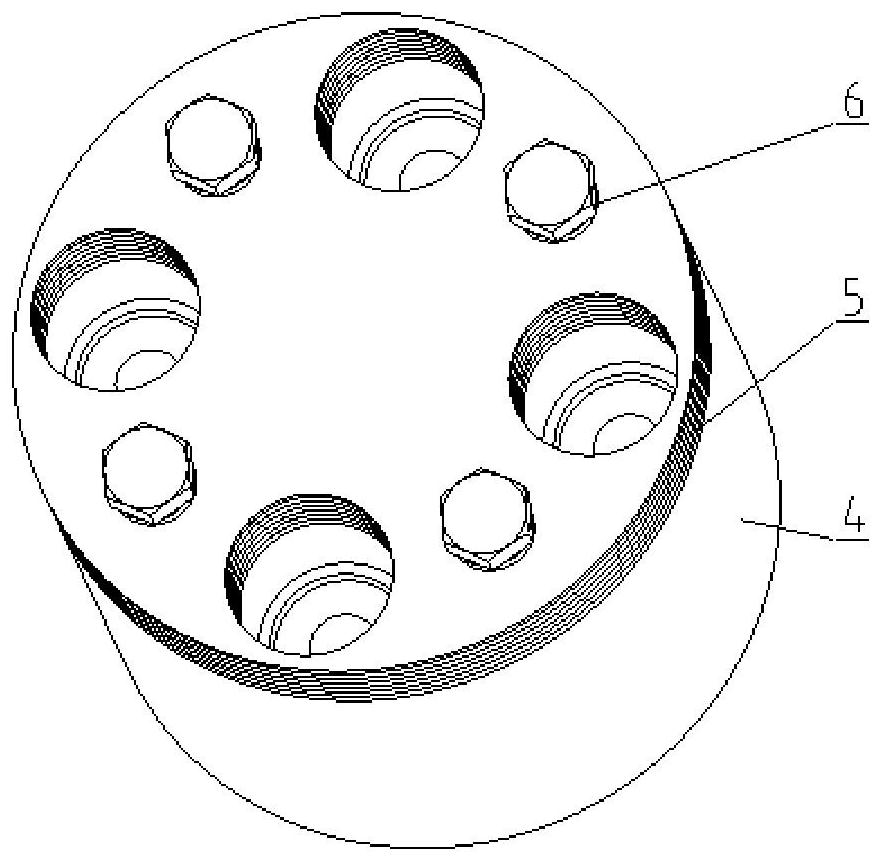

[0035] Such as figure 1 As shown, the shock absorber includes: a support assembly 13, a mass assembly 14 and a spring assembly 15; as figure 2 As shown, the support assembly 13 includes: a support plate 1, a support rod 2 and a fastener I3; as image 3 As shown, the mass assembly 14 includes: a mass block 4, a mass sheet 5 and a fastener II 6; as Figure 4 As shown, the spring assembly 15 includes: a guide rod 7, a positioning cylinder 8, a spring 9, a positioning pin 10, a positioning nut 11 and a fastener III 12; wherein, each component of the shock absorber in this embodiment is made of metal (the mass 4 and mass sheet 5 are made of steel), which has the characteristics of stable performance, high and low temperature resistance, anti-corrosion and anti-rust, radiation resistance and oil resistance.

[0036] The connection relationship of the shock absorber is: four spring assemblies 15 are arranged in parallel, and the mass assembly 14 is clamped in the middle of each sp...

Embodiment 2

[0051] On the basis of Embodiment 1, the number of spring assemblies 15 can be changed, such as three, six or eight, so that the stability of the shock absorber can be further adjusted.

Embodiment 3

[0053] On the basis of Embodiment 1 or 2, the support rod 2 can be removed, the mounting holes can be added on the support plate 1, and the vibration absorber and vibration equipment can be fixed directly through the support plate 1, so as to adapt to different installation interfaces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com