Bacterial strain for producing reductive dehalogenase and application thereof

A technology of dehalogenase and strain, applied in the directions of enzymes, bacteria, enzymes, etc., can solve the problems of high requirements for equipment and operating conditions, difficult safe operation, low total yield, etc., achieving simple medium components and avoiding reaction time. The effect of long and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Classification of Pseudomonas strains

[0017] 1) Strain characteristics

[0018] The colony on the preservation medium was milky white opaque, nearly round, with a smooth and moist surface and regular edges; observed under a microscope, the bacteria were rod-shaped and Gram-negative; the physiological and biochemical indicators are shown in Table 1.

[0019] Table 1 Physiological and biochemical characteristics of strain YtRDases-55

[0020] project YtRDases-55 project YtRDases-55 Oxidase + VP test + H2S production - MR test - Nitrate reduction + indole production - Urease - Starch Utilization - gelatin liquefaction + Catalase +

[0021] 2) Strain identification

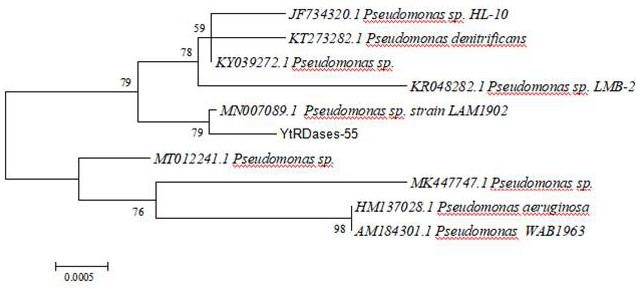

[0022] The length of the 16S rRNA gene sequence obtained by DNA extraction, PCR amplification and sequencing was 1439 bp, and the BLAST comparison was performed on GenBank and the phylogenetic tree was drawn ( figure 1 ), the base ...

Embodiment 2

[0031] 1. Activation of the strains: pick the strains and inoculate them on the slant medium: glucose 1g / L, yeast extract powder 5 g / L, peptone 10 g / L, NaCl 5 g / L, agar 20 g / L, pH7. 0, cultured in a constant temperature incubator at 30°C for 16 hours;

[0032] 2. Liquid fermentation: Pick a circle of activated strains on the slant and inoculate them in a 500mL Erlenmeyer flask with 50mL of fermentation medium at a speed of 200r / min and a temperature of 30°C to obtain a fermented liquid of reductive dehalogenase. Culture for 72h at 8000r / m min centrifuged for 20min to collect bacterial cells, the composition and final concentration of the fermentation medium were: glucose 5 g / L, 2,3,6-dichloropyridine 0.5 g / L, (NH 4 ) 2 SO 4 5g / L, KH 2 PO 4 1g / L, MgSO 4 0.2g / L, vitamin B 1 1mg / L, biotin 50μg / L, nicotinamide 1mg / L, calcium pantothenate 1mg / L, FeSO 4 1.6 mg / L, CuSO 4 94μg / L, ZnSO 4 0.23mg / L, sodium molybdate 0.17mg / L, boric acid 50μg / L, MnSO 4 0.38 mg / L, pH 7.0-7...

Embodiment 3

[0035] 1. Strain activation: pick the strains and inoculate them to the slant medium: glucose 1g / L, yeast extract powder 5 g / L, peptone 10 g / L, NaCl 5 g / L, agar 20 g / L, pH 7.0 , cultivated in a constant temperature incubator at 30°C for 16 hours;

[0036] 2. Liquid fermentation: Pick a circle of activated strains on the slant and inoculate them in a 500mL Erlenmeyer flask with 50mL of fermentation medium at a speed of 200r / min and a temperature of 30°C to obtain a fermented liquid of reductive dehalogenase. Culture for 72h at 8000r / m min centrifuged for 20min to collect bacterial cells, the composition and final concentration of the fermentation medium were: glucose 5 g / L, 2,3,6-dichloropyridine 0.5 g / L, (NH 4 ) 2 SO 4 5g / L, KH 2 PO 4 1g / L, MgSO 4 0.2g / L, vitamin B 1 1mg / L, biotin 50μg / L, nicotinamide 1mg / L, calcium pantothenate 1mg / L, FeSO 4 1.6 mg / L, CuSO 4 94μg / L, ZnSO 4 0.23mg / L, sodium molybdate 0.17mg / L, boric acid 50μg / L, MnSO 4 0.38 mg / L, pH 7.0-7.2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com