A kind of preparation method of plastic rubber powder

A rubber powder and plasticity technology, which is applied in the field of plastic rubber powder preparation, can solve the problems of low crushing efficiency, large rubber powder particles, and damage to rubber molecular chains, and achieve long processing time, good plasticity, and reduced internal friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

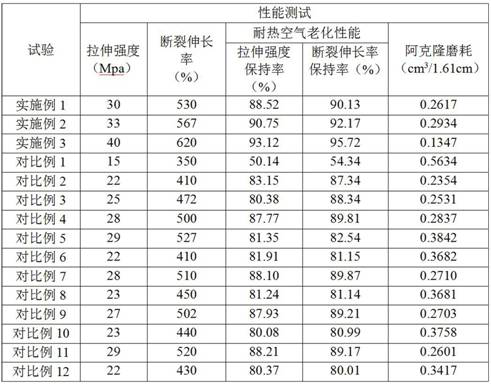

Examples

Embodiment 1

[0024] S1: Cut waste tires into small pieces, remove dust and pollutants on the surface by ultrasonic cleaning in deionized water for 15 minutes at room temperature; remove oil stains on the surface by ultrasonic cleaning with 5wt% NaOH solution for 30 minutes at room temperature; remove metal impurities by magnetic separation, and After crushing, 3-5cm pretreated rubber particles are obtained;

[0025] S2: Add the pretreated rubber particles described in step S1 to a hydrogen peroxide solution with a mass concentration of 10%, control the solid-to-liquid ratio to 1:10, adjust the pH to 1.8 with acetic acid and keep it, and stir for 40 minutes at room temperature , to obtain surface-modified rubber particles after filtering and draining;

[0026] S3: Disperse the surface-modified rubber particles described in step S2 in the ethanol solution, control the solid-to-liquid ratio to 1:15, stir and react at a temperature of 50°C for 15 minutes; then add trimethylacetic anhydride, th...

Embodiment 2

[0030] S1: Cut waste tires into small pieces, remove dust and pollutants on the surface by ultrasonic cleaning in deionized water for 20 minutes at room temperature; remove oil stains on the surface by ultrasonic cleaning with 5wt% NaOH solution for 40 minutes at room temperature; remove metal impurities by magnetic separation, and After crushing, 3-5cm pretreated rubber particles are obtained;

[0031] S2: Add the pretreated rubber particles described in step S1 to the hydrogen peroxide solution with a mass concentration of 15%, control the solid-to-liquid ratio to 1:20, adjust the pH to 2.2 with acetic acid and keep it, and stir for 70 minutes at room temperature , to obtain surface-modified rubber particles after filtering and draining;

[0032] S3: Disperse the surface-modified rubber particles described in step S2 in the ethanol solution, control the solid-to-liquid ratio to 1:25, stir and react at a temperature of 80°C for 35 minutes; then add trimethylacetic anhydride, ...

Embodiment 3

[0036] S1: Cut waste tires into small pieces, remove dust and pollutants on the surface by ultrasonic cleaning in deionized water for 20 minutes at room temperature; remove oil stains on the surface by ultrasonic cleaning with 5wt% NaOH solution for 30 minutes at room temperature; remove metal impurities by magnetic separation, and After crushing, 3-5cm pretreated rubber particles are obtained;

[0037] S2: Add the pretreated rubber particles described in step S1 to a hydrogen peroxide solution with a mass concentration of 15%, control the solid-to-liquid ratio to 1:15, adjust the pH to 2.0 with acetic acid and keep it, and stir for 55 minutes at room temperature , to obtain surface-modified rubber particles after filtering and draining;

[0038] S3: Disperse the surface-modified rubber particles described in step S2 in the ethanol solution, control the solid-to-liquid ratio to 1:20, stir and react at a temperature of 65°C for 25 minutes; then add trimethylacetic anhydride, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com