Device and method for mineralizing and fixing CO2 and preparing fine calcium carbonate by carbide slag

A carbide slag, solid technology, applied in chemical instruments and methods, preparation/separation of calcium carbonate/strontium/barium, ammonia, etc., can solve the problem of lack of equipment design, consumption of carbonizing agent, not considering ammonia gas treatment and overflow risks, etc. problem, to achieve the effect of large-scale industrial application and easy to scale up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

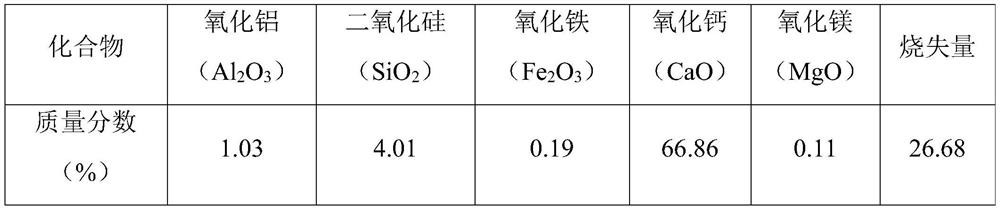

[0055] Carbide slag raw material A was selected as the experimental raw material, and its main element composition is shown in Table 1.

[0056] Table 1 The main element composition of carbide slag raw material A

[0057]

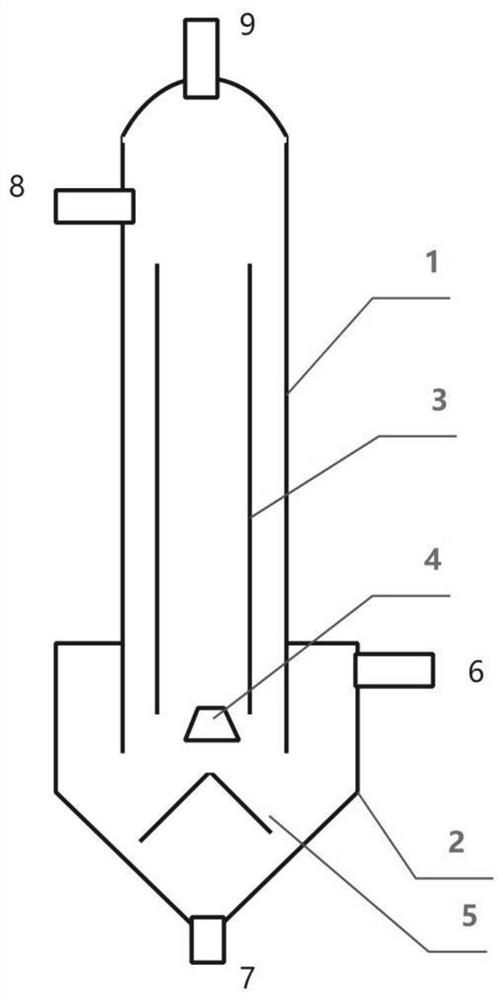

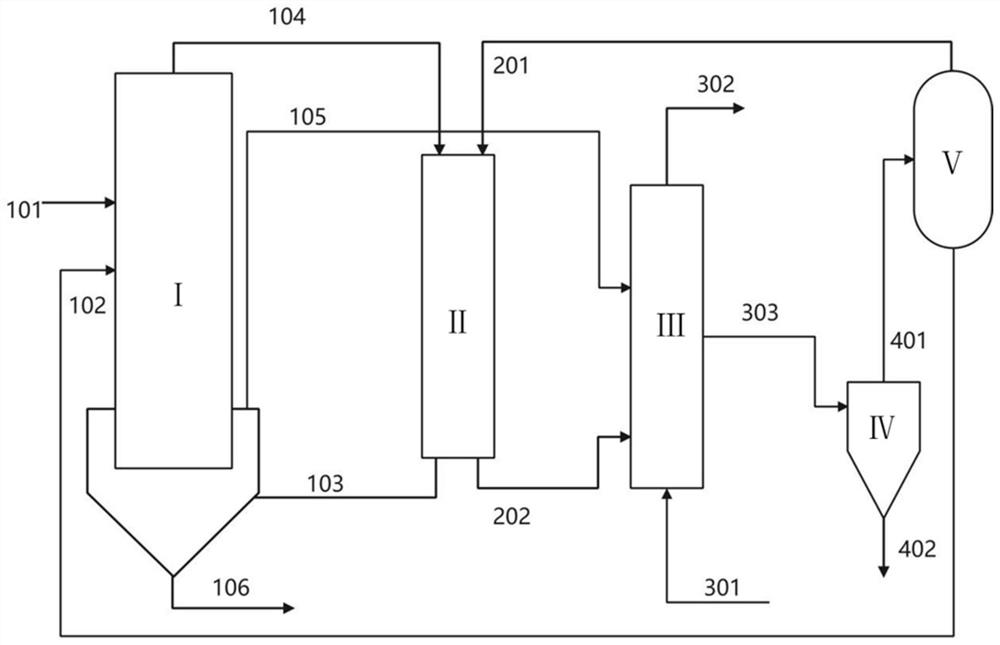

[0058] Carbide slag raw material A is dried for 2 hours, and after removing volatile components such as sulfide and organic matter, it is ground to 100 mesh, and the ground carbide slag is added to the circulation from the solid / liquid material inlet 8 at a rate of 0.5kg / h. - Separation and integrated slag melting reactor 1 (height-to-diameter ratio is 9.5, the inner diameter ratio of the draft tube and the reactor is 0.75, the height ratio of the draft tube and the reactor is 0.84, the solid-liquid separator and the reactor The volume ratio is 0.3, and the ratio of the two diameters is 1:7:1), and at the same time, the ammonium chloride solution with a mass fraction of 10% is added to the circulation-separation by the solid / liquid material inlet 8 at a ...

Embodiment 2

[0060] The carbide slag A of Example 1 was selected as the experimental raw material, and the experimental process was basically the same, except that the carbide slag was pre-mixed to form a suspension and then added to the reactor, and different solution concentration parameters and reactor parameters were selected. The specific operations were as follows: Carbide slag raw material A was dried for 2 hours, after removing volatile components such as sulfide and organic matter therein, it was ground to 200 mesh, and the carbide slag after grinding was mixed with 6.39kg / h ammonium chloride solution ( The mass fraction is 20%) mixed to make a suspension from the solid / liquid material inlet 8 into the loop-separation integrated slag reactor I (height-to-diameter ratio is 8, and the inner diameter ratio of the draft tube and the reactor is 0.6 , the height ratio of the draft tube and the reactor is 0.7, the volume ratio of the solid-liquid separator to the reactor is 0.5, and the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com