Soft carbon negative electrode material and preparation method and application thereof

A negative electrode material, soft carbon technology, applied in the direction of negative electrodes, battery electrodes, active material electrodes, etc., can solve the problems of low capacity retention rate, low initial discharge capacity, and low compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

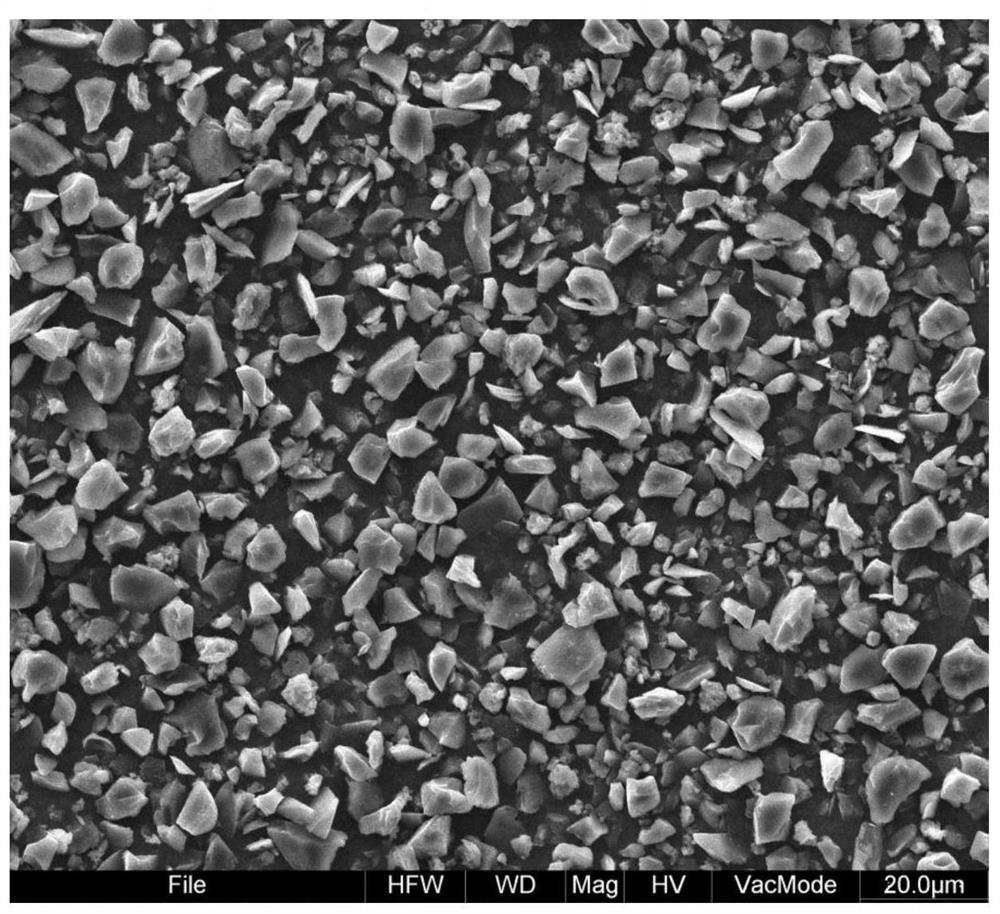

Image

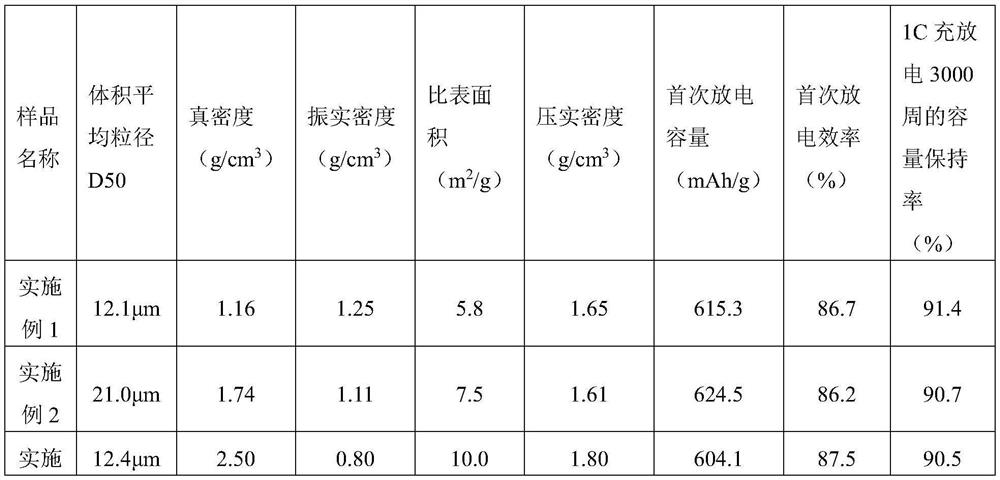

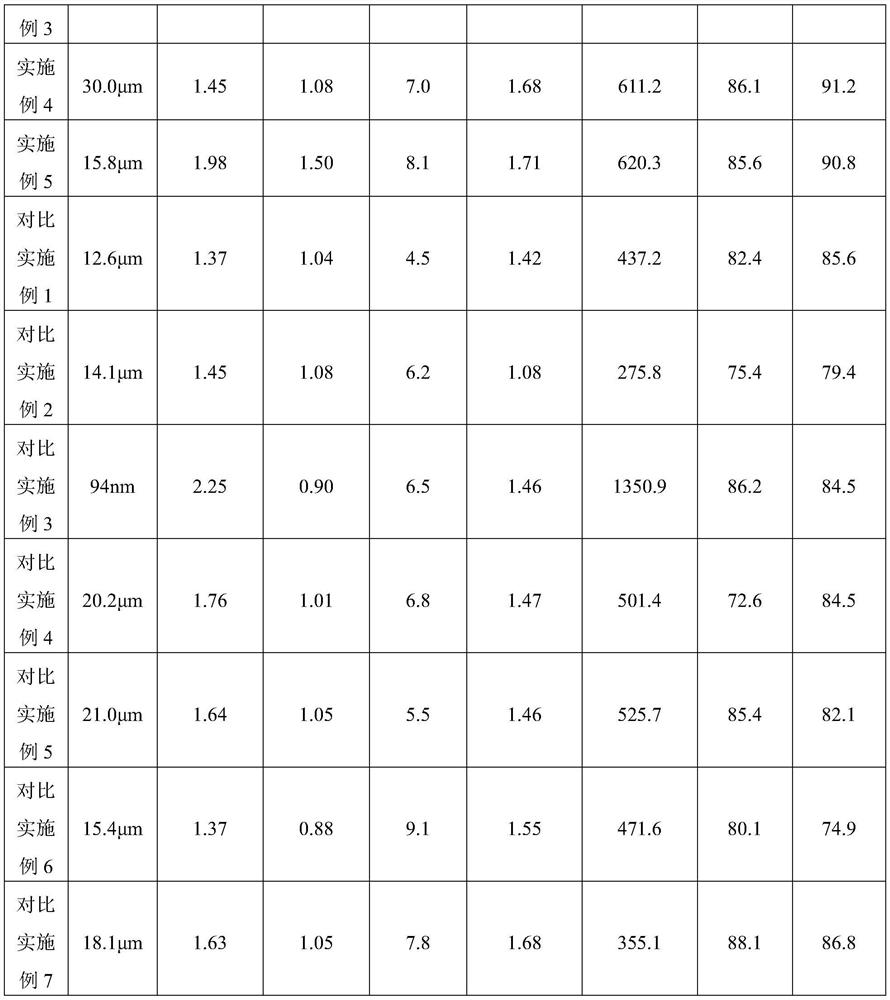

Examples

Embodiment 1

[0065] The preparation of embodiment 1 soft carbon negative electrode material

[0066] Step (1): Polymerize coal tar at 800°C for 40 hours to obtain mesocarbon microspheres;

[0067] Step (2): The mesophase carbon microspheres were fused at 80°C for 3 minutes, then pulverized with a pulverizer at a speed of 500 rpm, passed through a 200-mesh sieve, and the under-sieve was taken in an inert atmosphere at Carry out pre-carbonization treatment at 900°C for 16 hours to obtain a carbon precursor;

[0068] Step (3): The carbon precursor is pulverized with a pulverizer at a speed of 800 rpm, and then classified by a classifier with a frequency of 200 Hz to obtain a carbon precursor with a volume average particle diameter D50 of 15.3 μm. body particles, the carbon precursor particles were carbonized and heat-treated at 2000°C for 30 hours in an inert atmosphere to obtain carbonized particles;

[0069] Step (4): The carbonized particles were mixed with single crystal silicon having ...

Embodiment 2

[0070] The preparation of embodiment 2 soft carbon negative electrode material

[0071] Step (1): Polymerizing coal tar at 600°C for 40 hours to obtain mesophase carbon microspheres;

[0072] Step (2): The mesocarbon microspheres were fused at 80° C. for 5 minutes, then pulverized with a pulverizer at a speed of 300 rpm, passed through a 200-mesh sieve, and the under-sieve was taken in an inert atmosphere at Carry out pre-carbonization treatment at 200°C for 48 hours to obtain a carbon precursor;

[0073] Step (3): The carbon precursor is pulverized by a pulverizer at a speed of 500 rpm, and then classified by a classifier with a frequency of 300 Hz to obtain a carbon precursor with a volume average particle diameter D50 of 22.9 μm. Carbide particles, the carbon precursor particles were carbonized and heat-treated at 1600°C for 30 hours in an inert atmosphere to obtain carbonized particles;

[0074] Step (4): The carbonized particles were mixed with single crystal silicon ha...

Embodiment 3

[0075] The preparation of embodiment 3 soft carbon negative electrode material

[0076] Step (1): Polymerize coal tar at 700°C for 30 hours to obtain mesophase carbon microspheres;

[0077] Step (2): The mesocarbon microspheres were fused at 65° C. for 4 minutes, then pulverized with a pulverizer at a speed of 400 rpm, passed through a 200-mesh sieve, and the under-sieve was taken in an inert atmosphere at Carry out pre-carbonization treatment at 550°C for 32 hours to obtain a carbon precursor;

[0078] Step (3): The carbon precursor is pulverized with a pulverizer at a speed of 650 rpm, and then classified by a classifier with a frequency of 250 Hz to obtain a carbon precursor with a volume average particle diameter D50 of 15.3 μm. body particles, the carbon precursor particles were carbonized and heat-treated at 1800°C for 45 hours in an inert atmosphere to obtain carbonized particles;

[0079] Step (4): The carbonized particles were mixed with single crystal silicon havin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com