Preparation method and application of fragrant raw material manifesting sweet taste characteristics of Chinese style cigarettes

A technology for raw materials and cigarettes, which is applied in the field of synthesis of tobacco flavor raw materials, and achieves the effects of wide application prospects, improved reaction yield, and increased smoke permeability and fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

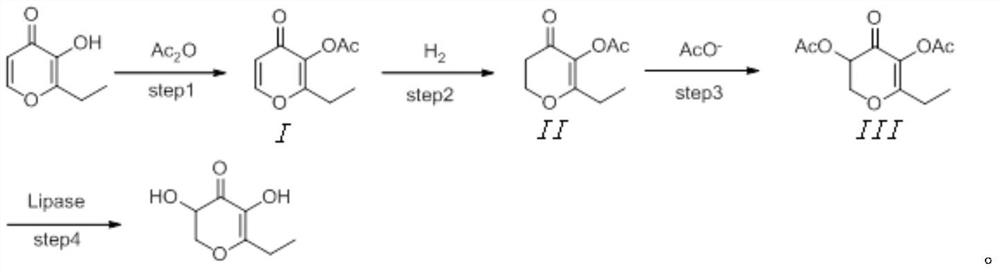

Method used

Image

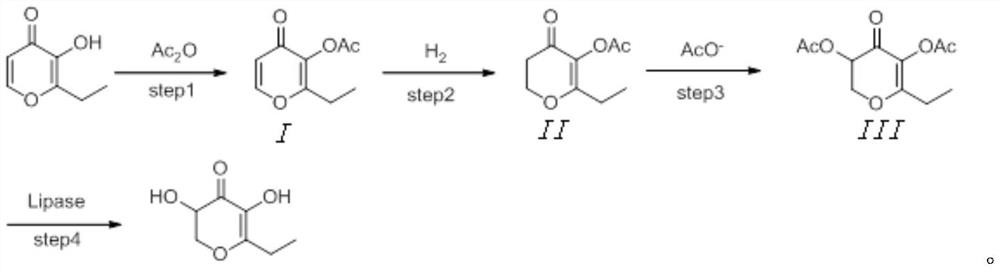

Examples

Embodiment 1

[0031] Preparation of ethyl maltophenate: In a 50 ml round bottom flask, ethyl maltol (1.40 g, 10 mmol) and acetic anhydride (2.04 g, 20 mmol) were added, and the reaction was added to the reaction mixture after 90 ° C for 6 h. 100 ml of ethyl acetate dilution, mixed with a saturated sodium bicarbonate solution under stirring, until no bubble is generated, the organic phase was washed twice with saturated NaCl solution, and the organic layer was separated and anhydrous Na 2 SO 4 Dry, evaporated, evaporated, 78 g of light yellow oil, yield 97.8%, product ethyl maltophenate can be directly carried out.

[0032] Preparation of dihydroethyl maltophenate: In a 100 mL round bottom flask, ethyl maltophenate (1.82 g, 10 mmol), 5% palladium carbon (0.2 g) was added to the round bottom flask, respectively. Ethyl acetate was 20 ml, and nitrogen replacement was replaced by hydrogen, then hydrogen was reacted at room temperature under hydrogen atmosphere (TLC monitoring, the feedstock reaction...

Embodiment 2

[0036] Preparation of ethyl maltophenate: Ethyl maltol (1.40 g, 10 mmol) and acetyl chloride (1.57 g, 20 mmol) were sequentially added, and the reaction was added to the reaction mixture after 6 h, 90 ° C for 6 h. 100 ml of ethyl acetate dilution, mixed with saturated sodium hydrogencarbonate solution at batch under stirring, until no bubble is formed. Wash the organic phase twice with a saturated NaCl solution, divide the organic layer and use anhydrous NA 2 SO 4 Dry, evaporated, evaporated, evaporated, endocyanic oil, ethyl maltophenate, 1.64 g, yield 90.1%, ethyl maltophenate can be directly carried out.

[0037]Preparation of dihydroethyl maltophenate: In the 100 ml round bottom flask, ethyl maltophenate (1.82 g, 10 mmol), Ray nickel (0.2 g), acetic acid is added to the round bottom flask. Ethyl ester 20 mL, nitrogen replacement 3, hydrogen replacement 3 h then reacted under a hydrogen atmosphere (TLC monitoring, the feedstock reaction immediately stopped). The reaction liquid...

Embodiment 3

[0041] Preparation of ethyl maltophenate: Ethyl maltol (1.40 g, 10 mmol) and acetic anhydride (1.02 g, 10 mmol) were sequentially added, and the reaction was reacted at 90 ° C. After 6 h, 100 mL of ethyl acetate was added to the reaction mixture, and the saturated sodium bicarbonate solution was added batch under stirring, and the bubble was produced. Wash the organic phase twice with a saturated NaCl solution, divide the organic layer and use anhydrous NA 2 SO 4 Dry, evaporated, evaporated, evaporated, endocyanic oil, ethyl maltophenate, 1.62 g, yield of 89.0%, ethyl maltophenate can be directly carried out.

[0042] Preparation of dihydroethyl maltophenate: In a 100 ml round bottom flask, ethyl maltophenate (1.82 g, 10 mmol), three (triphenylphosphine) chlorination were added to the round bottom flask, respectively. (0.2 g), ethyl acetate 20 mL, nitrogen replacement 3 times, hydrogen replacement 3 hits, then reacted under a hydrogen atmosphere (TLC monitoring, the feedstock reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com