Tobacco extract, preparation method and application thereof and tobacco product

A technology of tobacco extract and tobacco, which is applied in the fields of tobacco, application, and treatment of tobacco, and can solve problems such as unfavorable smoking of cigarettes, difficulty in large-scale production, increased irritation and waxy smell of smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

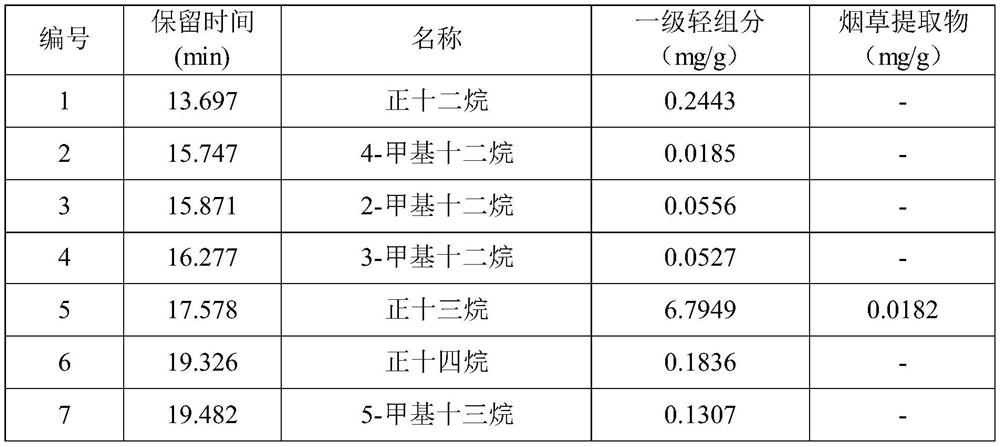

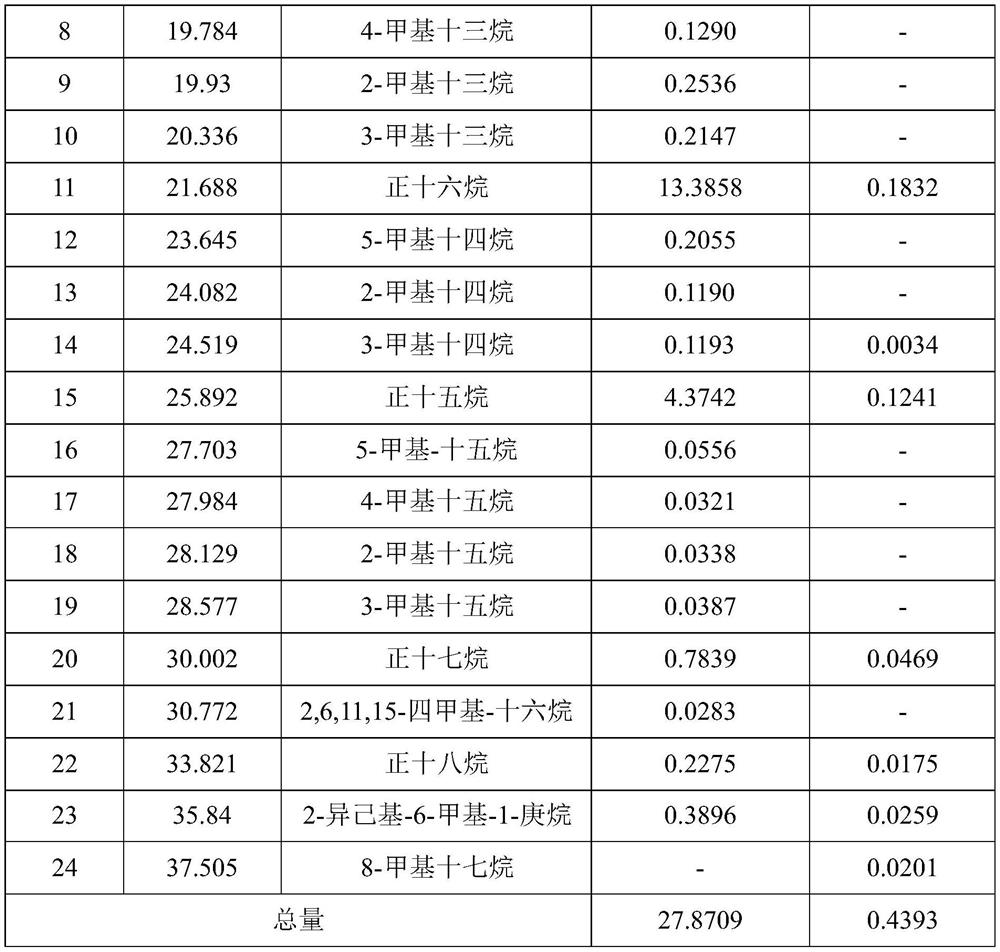

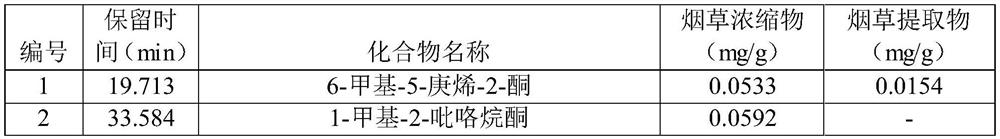

Examples

Embodiment 1

[0035] The preparation method of the tobacco extract of the present embodiment is as follows:

[0036] (1) Pulverize the tobacco leaves to 100 mesh, transfer to the subcritical extraction kettle, then add dimethyl ether, the mass ratio of tobacco leaf powder to dimethyl ether is 1:8, and the entraining agent is 95% ethanol (the amount is dimethyl ether 5% of the volume), extracted at 25°C for 2 hours, the extraction pressure was the saturated vapor pressure of dimethyl ether at this temperature, and evaporated under reduced pressure after the extraction was completed to obtain tobacco extract;

[0037] (2) Add 5 times the mass of 95% ethanol to the tobacco extract obtained in step (1), heat to 30°C and keep it for 60min to fully dissolve it; then cool to room temperature, and transfer to -20°C refrigerator to freeze 8h; low-temperature suction filtration to obtain the filtrate, and the filtrate was concentrated under reduced pressure until ethanol-free to obtain a tobacco conc...

Embodiment 2

[0040] The preparation method of the tobacco extract of the present embodiment is as follows:

[0041] (1) Pulverize the tobacco leaves to 100 mesh, transfer to the subcritical extraction kettle, then add dimethyl ether, the mass ratio of tobacco leaf powder and dimethyl ether is 1:10, entrainer absolute ethanol (consumption is dimethyl ether volume 10% of 10%), extracted at 40°C for 0.5h, the extraction pressure was the saturated vapor pressure of dimethyl ether at this temperature, and evaporated under reduced pressure after the extraction was completed to obtain tobacco extract;

[0042] (2) Add 10 times the mass of absolute ethanol to the tobacco extract obtained in step (1), heat it to 50°C and keep it for 20 minutes to fully dissolve it; then cool it to room temperature, and transfer it to a -5°C refrigerator to freeze 24h; centrifuge at low temperature (4000rpm, 10min), and concentrate the supernatant under reduced pressure until ethanol-free to obtain tobacco concentra...

Embodiment 3

[0045] The preparation method of the tobacco extract of the present embodiment is as follows:

[0046] (1) Crush the tobacco leaves to 50 mesh, transfer them to a subcritical extraction kettle, then add butane, the ratio of tobacco leaf powder to butane is 1:20, extract at 50°C for 1 hour, and the extraction pressure is butane at Saturation vapor pressure at this temperature, evaporate under reduced pressure after extraction finishes, obtain tobacco extract;

[0047](2) Add 8 times the mass of absolute ethanol to the tobacco extract obtained in step (1), heat to 40°C and keep it for 40min to fully dissolve it; then cool to room temperature, and transfer to -15°C refrigerator to freeze 12h; centrifuge at low temperature (4000rpm, 10min), and concentrate the supernatant under reduced pressure until ethanol-free to obtain tobacco concentrate;

[0048] (3) Transfer the tobacco concentrate obtained in step (2) to a molecular distillation feed tank, and carry out primary molecular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com