Functionalized boron nitride nanosheet/MXene/polybenzimidazole high-thermal-conductivity composite film and preparation method thereof

A technology of benzimidazole and composite film, which is applied in the field of composite materials, can solve the problems of insufficient thermal conductivity and other problems, and achieve the effect of simple method, wide application prospect and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

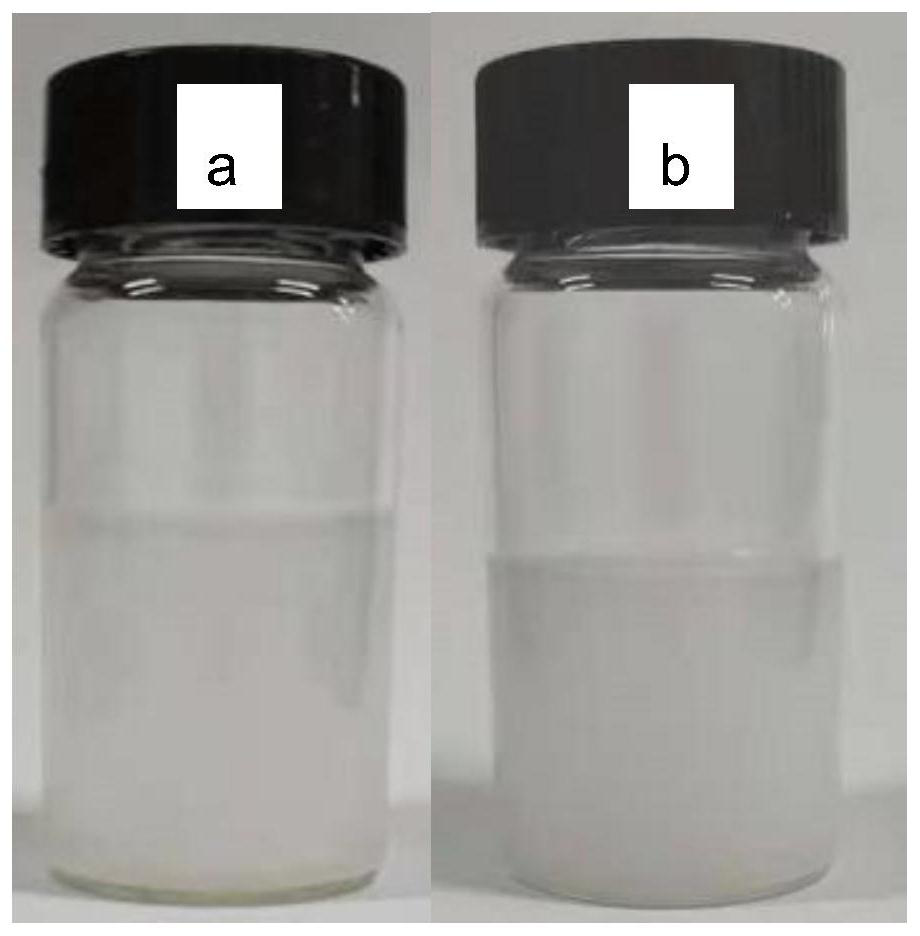

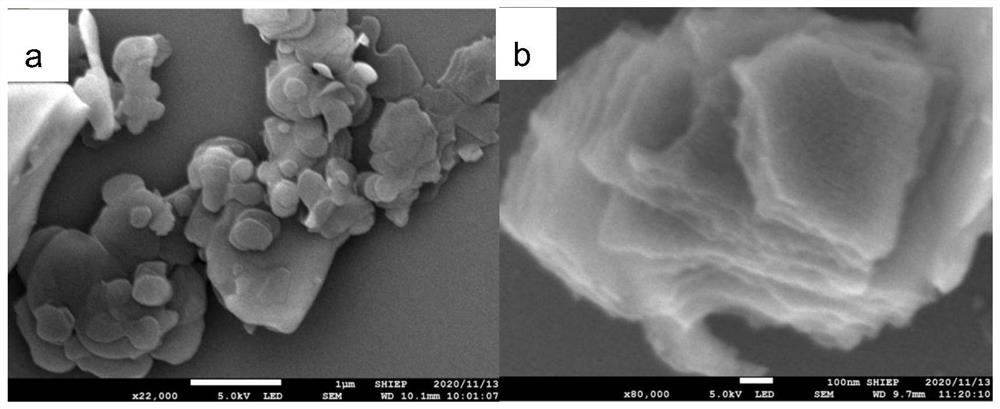

[0038] A preparation method of a composite film containing 1wt% boron nitride nanosheet / MXene mixed filler, the specific steps are as follows:

[0039] (1) The boron nitride powder was calcined under nitrogen gas in a tube furnace at 1000°C for 3h.

[0040] (2) 1 g of calcined boron nitride powder and 5 g of urea were placed in a round-bottomed flask, and under nitrogen gas, the oil bath was heated to 140° C. for a melting reaction for 6 h.

[0041] (3) After the reaction is completed, disperse the solid in 500ml deionized water, and perform ultrasonic stripping treatment for 10h to obtain a dispersion, then centrifuge the dispersion at 3000rpm for 10min to obtain a supernatant; filter the supernatant, and deionize The filter cake is washed, and the filtering method is preferably suction filtration, and the collected solid is dried at 60° C. for 10 h to obtain urea-functionalized boron nitride nanosheets.

[0042] (4) Add 1g of Ti 3 AlC 2 Gradually and slowly added to 20ml ...

Embodiment 2

[0046] A preparation method of a composite film containing 5wt% boron nitride nanosheet / MXene mixed filler, the specific steps are as follows:

[0047] (1) The boron nitride powder was calcined under nitrogen gas in a tube furnace at 1000°C for 3h.

[0048] (2) 1 g of calcined boron nitride powder and 5 g of urea were placed in a round-bottomed flask, and under nitrogen gas, the oil bath was heated to 140° C. for a melting reaction for 6 h.

[0049] (3) After the reaction is completed, disperse the solid in 500ml deionized water, and perform ultrasonic stripping treatment for 10h to obtain a dispersion, then centrifuge the dispersion at 3000rpm for 10min to obtain a supernatant; filter the supernatant, and deionize Washing, the method of filtering is preferably suction filtration, and drying the collected solid at 60° C. for 10 h to obtain urea-functionalized boron nitride nanosheets.

[0050] (4) Add 1g of Ti 3 AlC 2 Gradually and slowly added to 20ml of 40wt% hydrofluoric...

Embodiment 3

[0054] A preparation method of a composite film containing 10wt% boron nitride nanosheet / MXene mixed filler, the specific steps are as follows:

[0055] (1) The boron nitride powder was calcined under nitrogen gas in a tube furnace at 1000°C for 3h.

[0056] (2) 1 g of calcined boron nitride powder and 5 g of urea were placed in a round-bottomed flask, and under nitrogen gas, the oil bath was heated to 140° C. for a melting reaction for 6 h.

[0057] (3) After the reaction is completed, disperse the solid in 500ml deionized water, and perform ultrasonic stripping treatment for 10h to obtain a dispersion, then centrifuge the dispersion at 3000rpm for 10min to obtain a supernatant; filter the supernatant, and deionize Washing, the method of filtering is preferably suction filtration, and drying the collected solid at 60° C. for 10 h to obtain urea-functionalized boron nitride nanosheets.

[0058] (4) Add 1g of Ti 3 AlC 2 Gradually and slowly added to 20ml of 40wt% hydrofluori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com