Preparation method of special PPS toughening agent

A technology of toughening agent and initiator, which is applied in the field of preparation of special toughening agent for PPS to achieve the effects of reducing side reactions, optimizing the reaction temperature and increasing the amount of grafting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

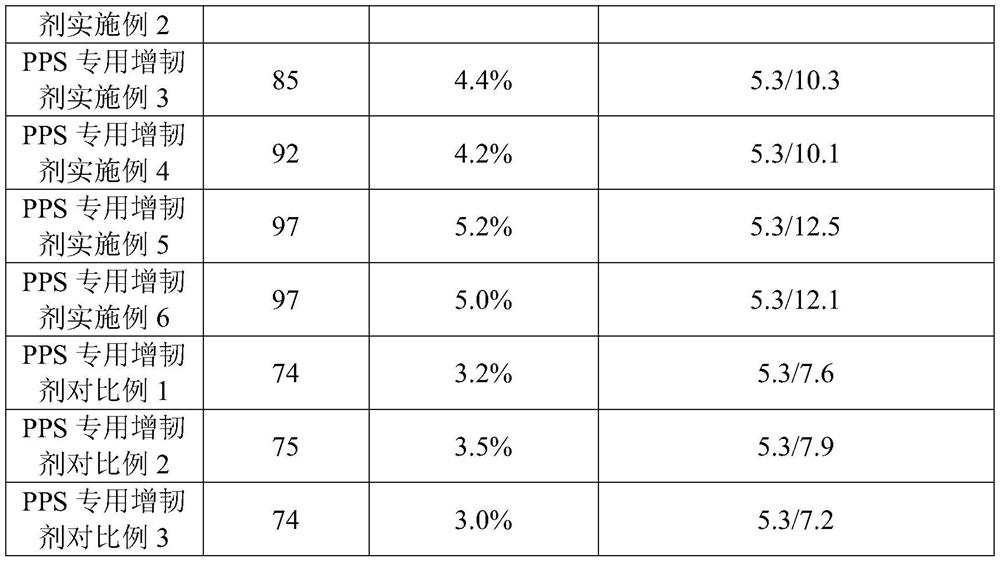

Examples

Embodiment 1

[0036] Preparation of special toughening agent for PPS:

[0037] First, 300 kg of xylene and 100 kg of POE (ethylene-1-octene copolymer) with a melting point of 52°C were added to the reactor, and stirred while heating. At the same time, 30 kg of GMA and 1.5 kg of initiators (DCP, BPO, TBPB According to the weight ratio 1:1:1) mix evenly, start dropping into the reactor at 100°C, drop it in 2 hours, raise the temperature to 120°C, keep it for 2 hours, then raise the temperature to 130°C, keep it for 2 hours, and continue to heat up to 140°C , keep warm for 2 hours; cool down to <40°C, add a mixed solvent of acetone and ethanol (mass ratio of acetone:ethanol is 1:1) to precipitate the product, wash 3 times; dry at 40-60°C for 24 hours to obtain the product.

Embodiment 2

[0039] Preparation of special toughening agent for PPS:

[0040] First, 280 kg of xylene and 80 kg of POE (ethylene-1-butene copolymer) with a melting point of 85°C were added to the reactor, and stirred while heating. At the same time, 25 kg of GMA and 1.0 kg of initiator (DCP, BPO, TBPB were (weight ratio 1:2:2 mixed) mixed evenly, 95 ℃ began to drop into the reactor, 2 hours after the drop, the temperature was raised to 115 ℃, kept for 2 hours, then heated to 126 ℃, kept for 2 hours, continued to heat up to 136 ℃, Insulate for 2 hours; cool down to <40°C, add a mixed solvent of acetone and ethanol (mass ratio of acetone:ethanol is 2:1) to precipitate the product, wash 3 times; dry at 40-60°C for 24 hours to obtain the product.

Embodiment 3

[0042] Preparation of special toughening agent for PPS:

[0043] First, 320 kg of xylene and 120 kg of POE (ethylene-1-hexene copolymer) with a melting point of 100°C were added to the reactor, and stirred while heating. At the same time, 35 kg of GMA and 3.0 kg of initiators (DCP, BPO, TBPB were (weight ratio 1:3:3 mixed) mix evenly, start dropping into the reactor at 105°C, drop it in 2 hours, raise the temperature to 125°C, keep it for 2 hours, then raise the temperature to 135°C, keep it for 2 hours, continue to heat up to 145°C, Insulate for 2 hours; cool down to <40°C, add a mixed solvent of acetone and ethanol (mass ratio of acetone:ethanol is 3:1) to precipitate the product, wash 3 times; dry at 40-60°C for 24 hours to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com