Polarized isobutylene-based polymer and its preparation method

A technology of isobutylene polymer and isobutylene base, applied in the field of polyolefin, to achieve the effect of large grafting amount, improving polarity and obvious difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] At -30°C, add 10 mL of PVC / dichloroethane solution (concentration: 0.03 g / mL, M w,PVC =99kg / mol, PDI=2.4) and 10mL of isobutene / dichloromethane (concentration: 2mol / L), the concentration of isobutene in the reaction system is 1mol / L. With stirring, add the solution containing iPrOH and FeCl 3 The mixed solution initiates the polymerization reaction, so that PVC, FeCl 3 , The molar ratio of iPrOH to isobutene is 2.5×10 -4 : 2.6×10 -2 : 3.6×10 -2 :1. Polymerize for 30 minutes, then add 2 mL of ethanol solution to terminate the reaction; after termination, the reaction system is dissolved in hexane and precipitated in ethanol in sequence, and washed three times to remove residual monomers, FeCl 3 After waiting, vacuum-drying at 40° C., the dried polarized isobutylene-based polymer can be obtained with a yield of 83%. The absolute weight-average molecular weight (M w ) is 140kg / mol, molecular weight distribution index (M w / M n ) is 4.0, and the polyisobutylene mas...

Embodiment 2

[0039] At -80°C, add 5mL PVC / dichloroethane solution (concentration: 0.04g / mL, M w,PVC =99kg / mol, PDI=2.4) and 25mL of isobutene / dichloromethane (concentration: 1mol / L), the concentration of isobutene in the reaction system is 0.83mol / L. With stirring, add the solution containing iPrOH and FeCl 3 The mixed solution initiates the polymerization reaction, in which PVC, FeCl 3 , The molar ratio of iPrOH to isobutene is 1.7×10 -4 : 1.0×10 -2 : 1.4×10 -2 :1. Polymerization reaction 10min. Termination reaction and aftertreatment method are the same as embodiment 1. Obtain the polarized isobutylene-based polymer after drying, yield is 83%, absolute weight-average molecular weight (M w ) is 124kg / mol, M w / M n is 1.4, and the mass content of polyisobutylene is 26%.

Embodiment 3

[0041] Add 20g PVC (M w,PVC =98kg / mol, PDI=1.8) and 1L dichloroethane, dissolved. Mix with 97 mL of isobutene at -30°C, and the concentration of isobutene in the reaction system is 1.0 mol / L. With stirring, add the solution containing iPrOH and FeCl 3 The mixed solution initiates the polymerization reaction, in which PVC, FeCl 3 , The molar ratio of iPrOH to isobutene is 4.8×10 -4 : 1.6×10 -2 : 2.24×10 -2 :1. Polymerization reaction 120min. Termination reaction and aftertreatment method are the same as embodiment 1. The polarized isobutylene-based polymer after drying was obtained with a yield of 36%. The absolute weight-average molecular weight (M w ) is 602kg / mol, M w / M n It is 2.1, and the mass content of polyisobutylene is 59%.

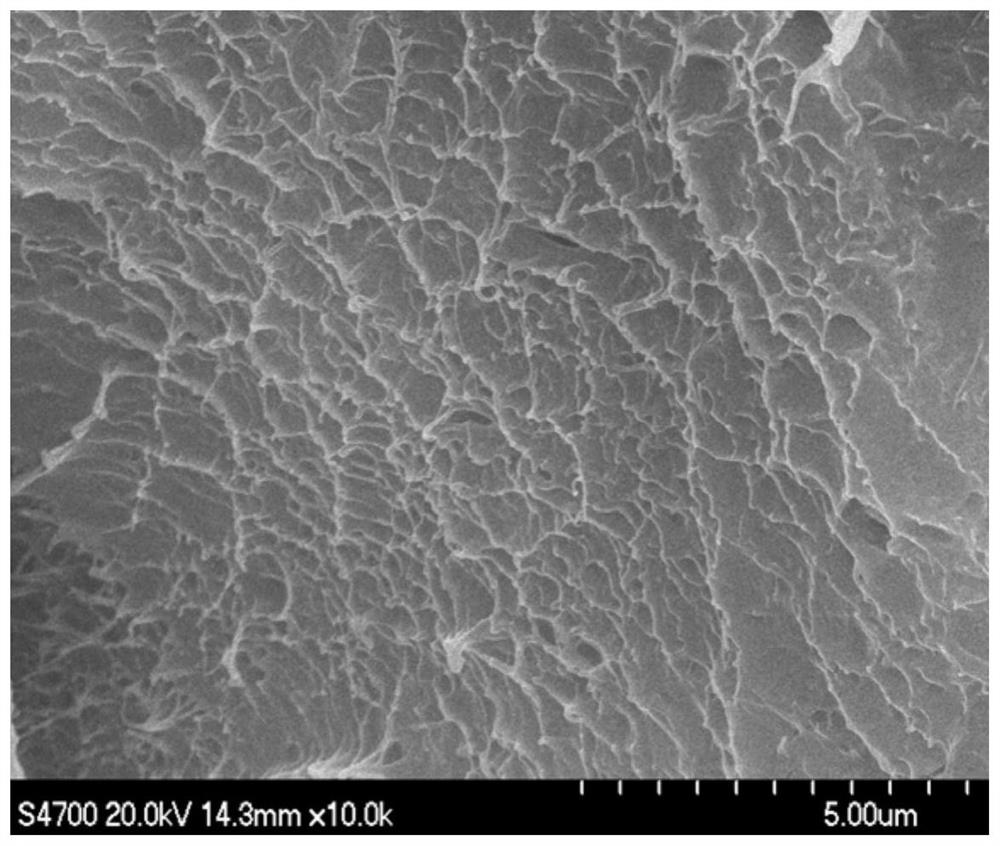

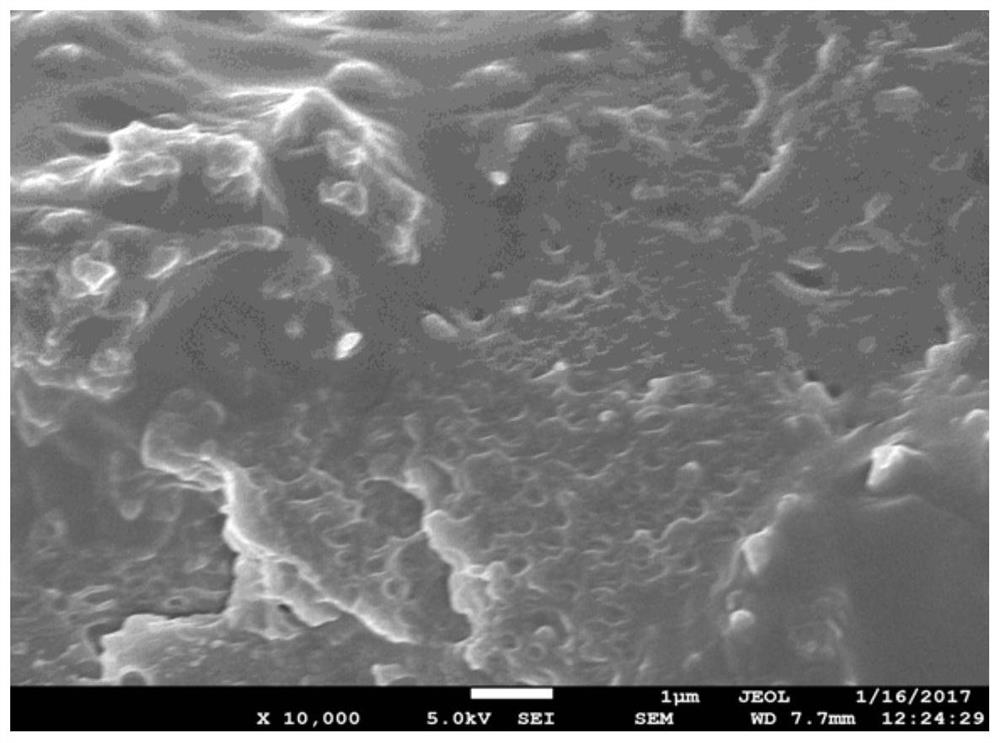

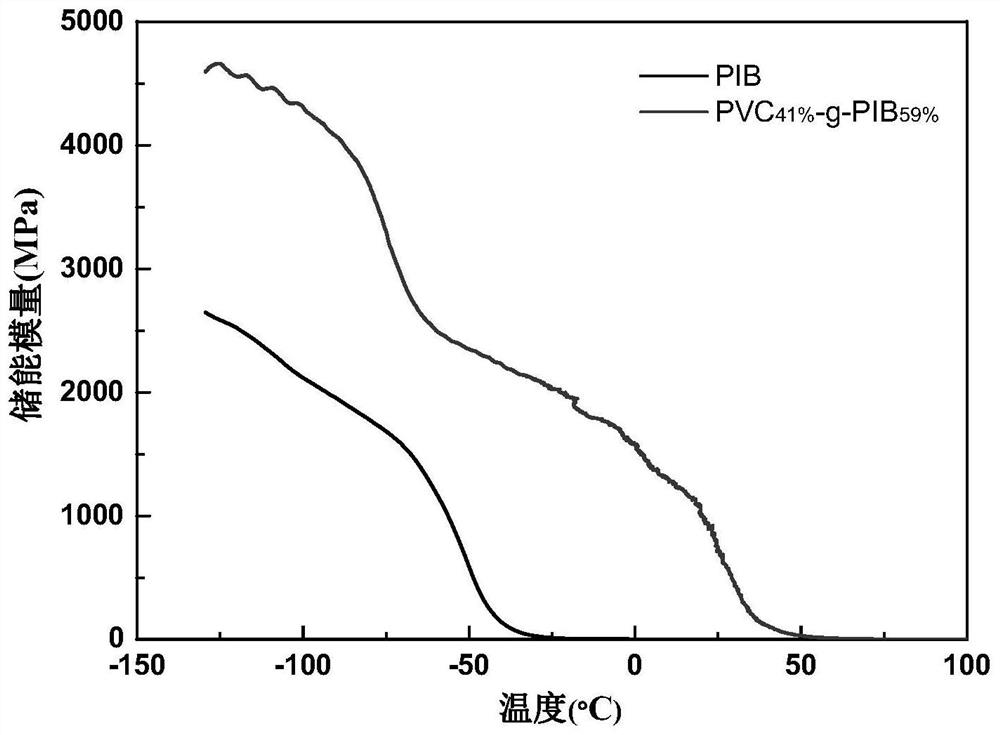

[0042] The cross-sectional SEM image of the above-mentioned polarized isobutylene-based polymer is as follows figure 1 As shown, it shows that a uniform and ordered phase separation structure is formed inside the polymer, resulting i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com