Silicon/carbon/iron oxide composite material and preparation method thereof

A composite material and iron oxide technology, which is applied in the field of silicon/carbon/iron oxide composite materials and their preparation, can solve the volume expansion of silicon-based materials and other problems, achieve high energy density, reduce pollutant emissions, and good cycle stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0033] A method for preparing a silicon / carbon / iron oxide composite material, comprising the steps of:

[0034] Step a, the catalytic oil slurry is pretreated to obtain clarified oil for use;

[0035] Step b, preparing a carbon-silicon composite material;

[0036] Step c, preparing silicon / carbon / iron oxide composite material.

[0037] In the preparation method of a silicon / carbon / iron oxide composite material described in this embodiment, the pretreatment of the catalytic oil slurry in step a is a vacuum distillation method.

[0038] A method for preparing a silicon / carbon / iron oxide composite material described in this embodiment, the method for preparing a carbon-silicon composite material in step b includes the following steps:

[0039] Step b1. Weigh the clarified oil and nano-silica powder according to the mass ratio, heat and stir the clarified oil at 40°C for 30 minutes, then add nano-silica powder, and mix evenly under ultrasonic conditions to obtain a mixture for u...

specific Embodiment approach 2

[0053] A method for preparing a silicon / carbon / iron oxide composite material, comprising the steps of:

[0054] Step a, the catalytic oil slurry is pretreated to obtain clarified oil for use;

[0055] Step b, preparing a carbon-silicon composite material;

[0056] Step c, preparing silicon / carbon / iron oxide composite material.

[0057] In the preparation method of a silicon / carbon / iron oxide composite material described in this embodiment, the pretreatment of the catalytic oil slurry in step a is a vacuum distillation method.

[0058] A method for preparing a silicon / carbon / iron oxide composite material described in this embodiment, the method for preparing a carbon-silicon composite material in step b includes the following steps:

[0059] Step b1. Weigh the clarified oil and nano-silica powder respectively according to the mass ratio, heat and stir the clarified oil at 30°C for 60 minutes, then add nano-silica powder, and mix uniformly under ultrasonic conditions to obtain...

specific Embodiment approach 3

[0072] A method for preparing a silicon / carbon / iron oxide composite material, comprising the steps of:

[0073] Step a, the catalytic oil slurry is pretreated to obtain clarified oil for use;

[0074] Step b, preparing a carbon-silicon composite material;

[0075] Step c, preparing silicon / carbon / iron oxide composite material.

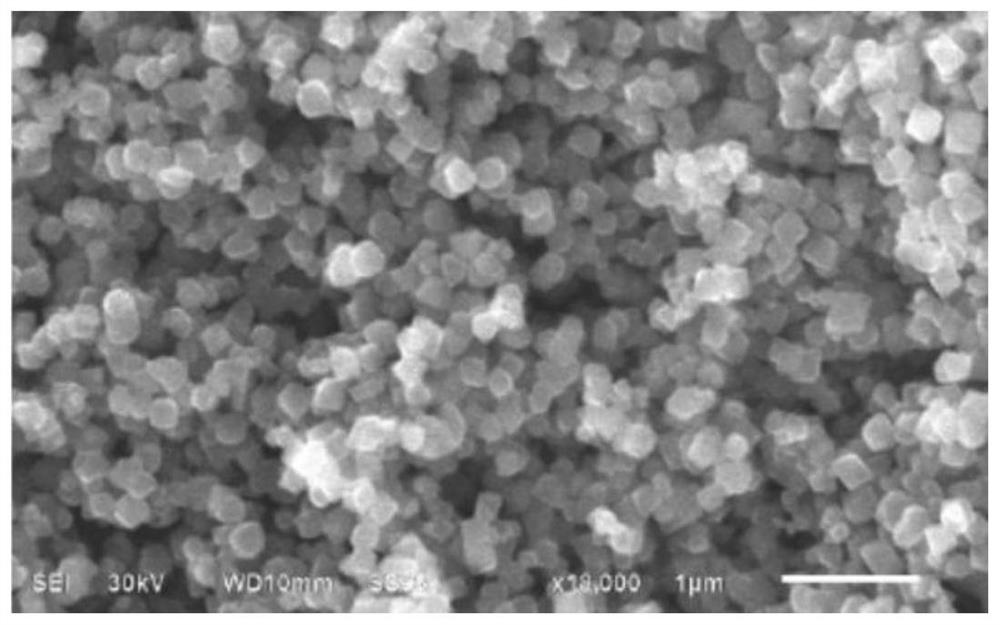

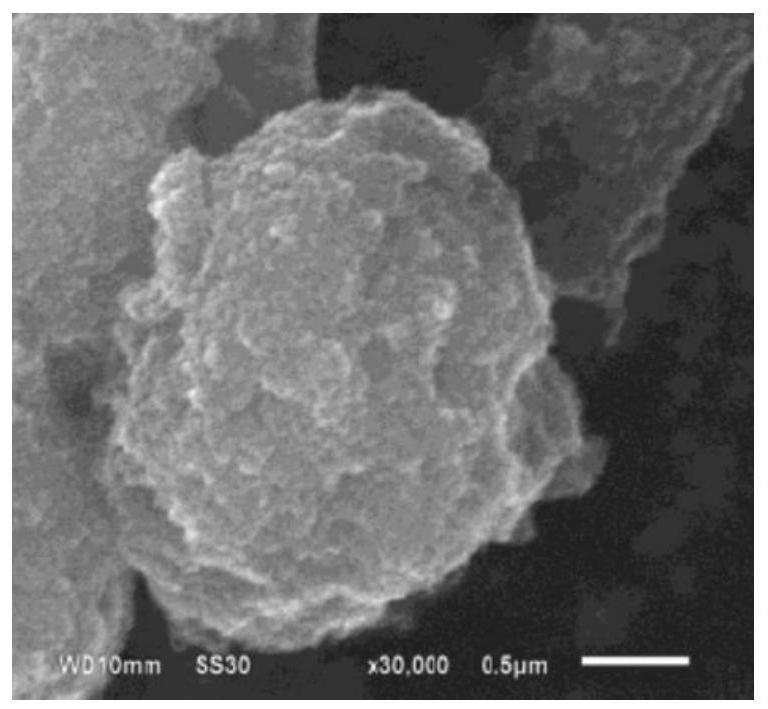

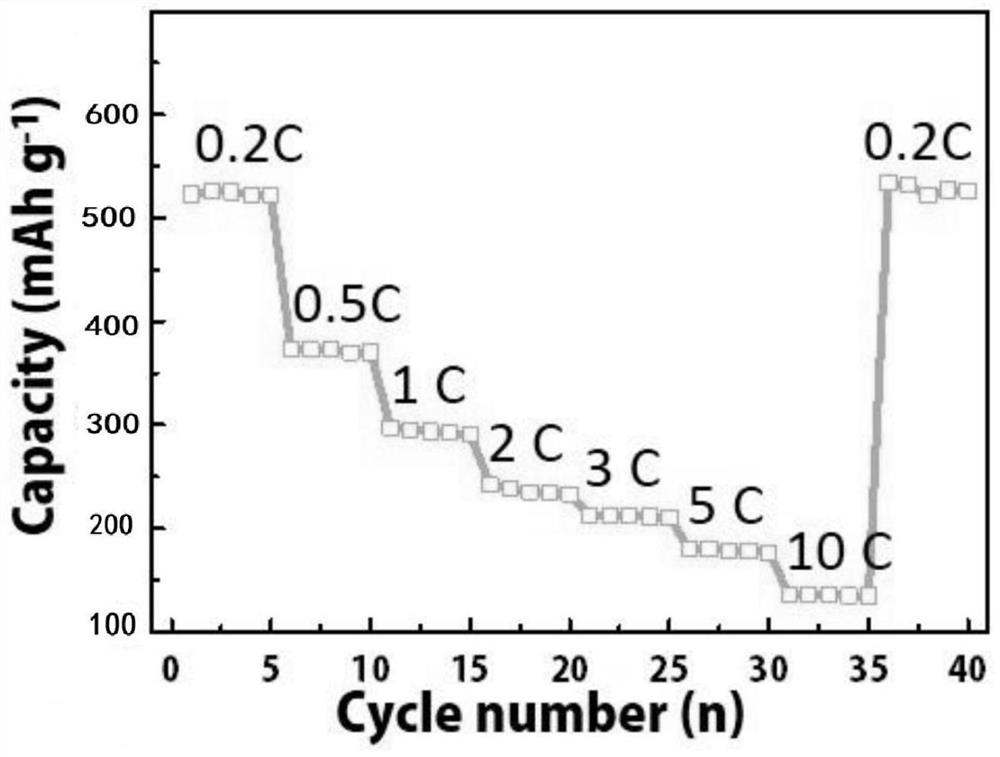

[0076] According to the preparation method of a silicon / carbon / iron oxide composite material described in this embodiment, the cycle performance comparison curve of a silicon / carbon / iron oxide composite material prepared at different temperatures is as follows Figure 5 As shown, the temperature marked in the figure is the set temperature when preparing the carbon-silicon composite material in step b, from Figure 5 It can be seen from the figure that the capacity of the silicon / carbon / iron oxide composite material can reach more than 550mAh / g. Through the regulation and design of the microscopic morphology and structure of silicon / carbon / iron oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com