Modified soft carbon negative electrode material, lithium ion battery, negative electrode material and preparation method

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, electrolyte battery manufacturing, secondary batteries, etc., can solve the problems of harsh preparation conditions, high equipment requirements, low reversible capacity, etc., and achieves increased pore lithium storage sites, The effect of improving the degree of amorphous and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The preparation of embodiment 1 modified soft carbon negative electrode material

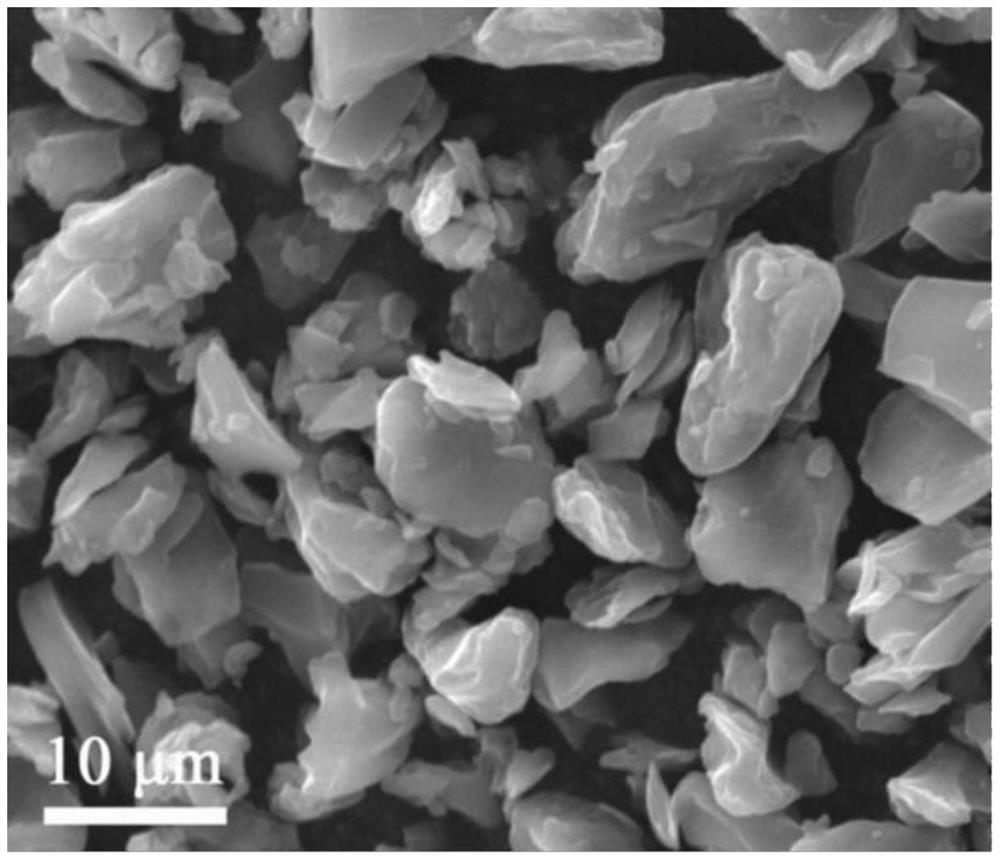

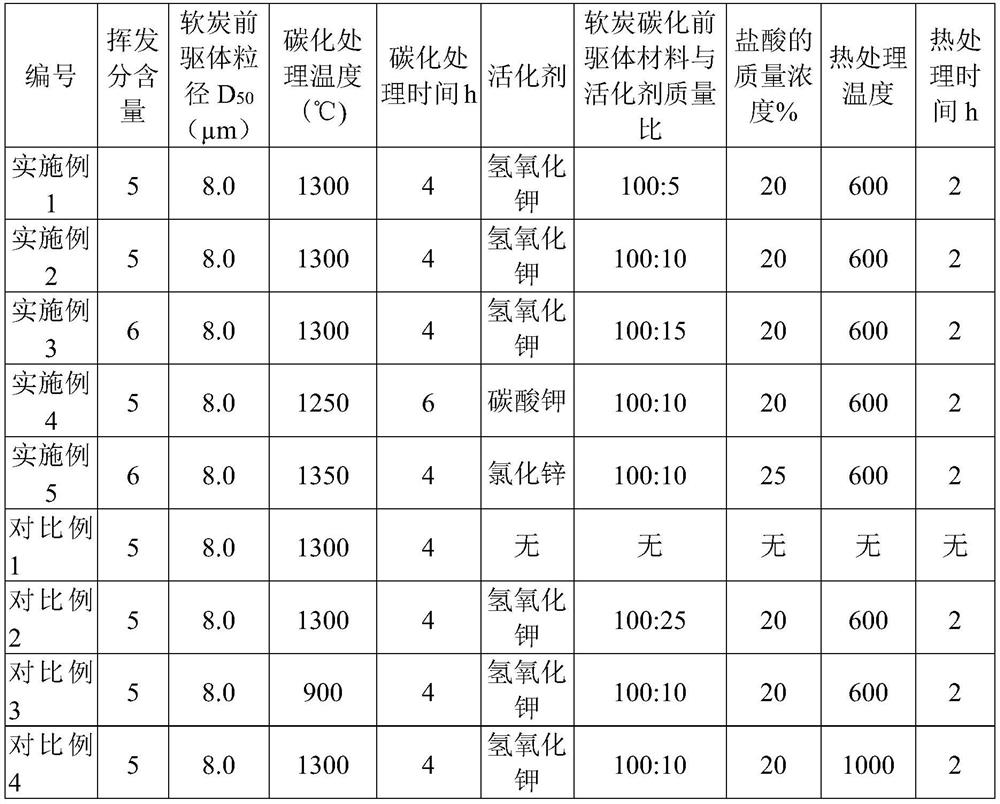

[0058] Needle coke with a volatile content of 5% was crushed by air flow and passed through a 200-mesh standard sieve to obtain needle coke powder with a particle size of 8.0 μm, and then placed in a roller kiln with nitrogen protection gas at 5 ° C / Min was raised to 1300°C, carbonized for 4 hours, and naturally cooled to room temperature to obtain a soft carbon carbonized precursor material; the above soft carbon carbonized precursor material was mixed with potassium hydroxide at a mass ratio of 100:5. Stir for 1 h at 1000 rpm. Then place it in a rotary furnace, raise the temperature to 800°C at a rate of 5°C / min under a nitrogen atmosphere, activate it for 2 hours, and cool down naturally. Next, add a hydrochloric acid solution with a mass fraction of 20%, stir and react at 50°C for 2 hours at a speed of 500rpm, then wash and filter with pure water until the filtrate pH=7.0, then dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com