Catalyst for preparing o-toluidine by hydrogenating o-nitrotoluene and preparation method of catalyst

A technology for o-nitrotoluene and o-toluidine is applied in the field of catalytic hydrogenation of o-nitrotoluene to prepare o-toluidine catalyst and the field of preparation thereof, and can solve the problems of easy crushing selectivity, poor thermal stability, low temperature and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

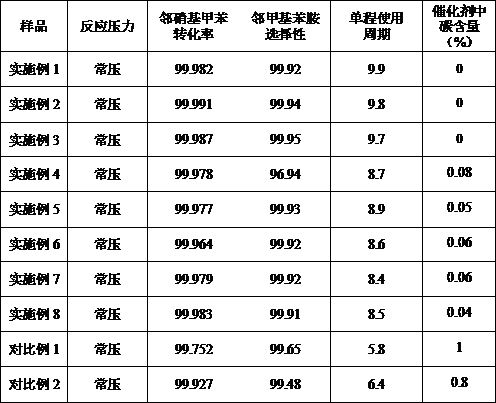

Examples

Embodiment 1

[0035] (1) Weigh 100g of raw silica gel and wash it with deionized water, put it into a reactor equipped with 200ml of deionized water, control the temperature of the reactor at 130°C, and the reaction pressure at 0.35MPa, and add concentrated nitric acid to adjust the solution under stirring conditions The acidity, adjust the concentration of nitric acid solution to 3%, the treatment time is 2h, and then wash with deionized water until the pH value of the washing solution is 7.0; (2) Weigh 100g copper nitrate and dissolve it in 180ml deionized water, the pH value of the solution is 5 , adding ammonia water with a specific gravity of 0.985 to the copper nitrate solution, controlling the pH value of the solution to be 10, forming a molecular formula of [Cu(NH 3 ) 4 ] 2+ copper ammonia complex, the copper content in the complex is 30g / l; (3) Add the copper ammonia complex obtained in step (2) into the dipping kettle, and add the modified silica gel obtained in step (1) Among t...

Embodiment 2

[0037](1) Weigh 100g of raw silica gel and wash it with deionized water, put it into a reactor equipped with 200ml of deionized water, control the temperature of the reactor at 140°C, and the reaction pressure at 0.25MPa, and add concentrated nitric acid to adjust the solution under stirring conditions The acidity, adjust the concentration of nitric acid solution to 4%, the treatment time is 2.5h, and then wash with deionized water until the pH value of the washing solution is 7.0; (2) Weigh 100g of copper nitrate and dissolve it in 180ml of deionized water, the pH of the solution is 4. Add ammonia water with a specific gravity of 0.985 to the copper nitrate solution, control the pH value of the solution to 9, and form a molecular formula of [Cu(NH 3 ) 4 ] 2+ copper ammonia complex, the copper content in the complex is 32g / l; (3) Add the copper ammonia complex obtained in step (2) into the dipping kettle, and add the modified silica gel obtained in step (1) Among them, at a ...

Embodiment 3

[0039] (1) Weigh 100g of raw silica gel and wash it with deionized water, put it into a reactor equipped with 200ml of deionized water, control the temperature of the reactor at 135°C, and the reaction pressure at 0.3MPa, and add concentrated nitric acid to adjust the solution under stirring conditions The acidity, adjust the concentration of nitric acid solution to 4%, the treatment time is 3h, and then wash with deionized water until the pH value of the washing solution is 7.0; (2) Weigh 100g copper nitrate and dissolve it in 180ml deionized water, the pH value of the solution is 6 , adding ammonia water with a specific gravity of 0.984 to the copper nitrate solution, controlling the pH of the solution to be 11, forming a molecular formula of [Cu(NH 3 ) 4 ] 2+ copper ammonia complex, the copper content in the complex is 35g / l; (3) Add the copper ammonia complex obtained in step (2) into the dipping kettle, and add the modified silica gel obtained in step (1) Among them, at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com