Preparation method of fuel cell membrane electrode

A fuel cell membrane and electrode technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of small and complex interface resistance, and the consistency of CCM membrane electrodes cannot be effectively guaranteed, and achieve the effect of avoiding swelling and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Membrane electrodes with an effective active area of 5*5cm are prepared by traditional one-time hot pressing:

[0019] Step 1. Weigh 25mg of 60% Pt / C catalyst, ultrasonically disperse it in 10mL of water, add 5mL of isopropanol and 3mL of DMF, stir thoroughly and then cool in an ice bath for ultrasonic dispersion;

[0020] Step 2. In the isopropanol of 12mL that the 5% Nafion solution that takes 0.2g is added, under ice-bath cooling ultrasonic dispersion condition, the mixed solution of Nafion and isopropanol is added dropwise to the solution prepared in the previous step, Cool in an ice bath and continue ultrasonic dispersion for 1 hour;

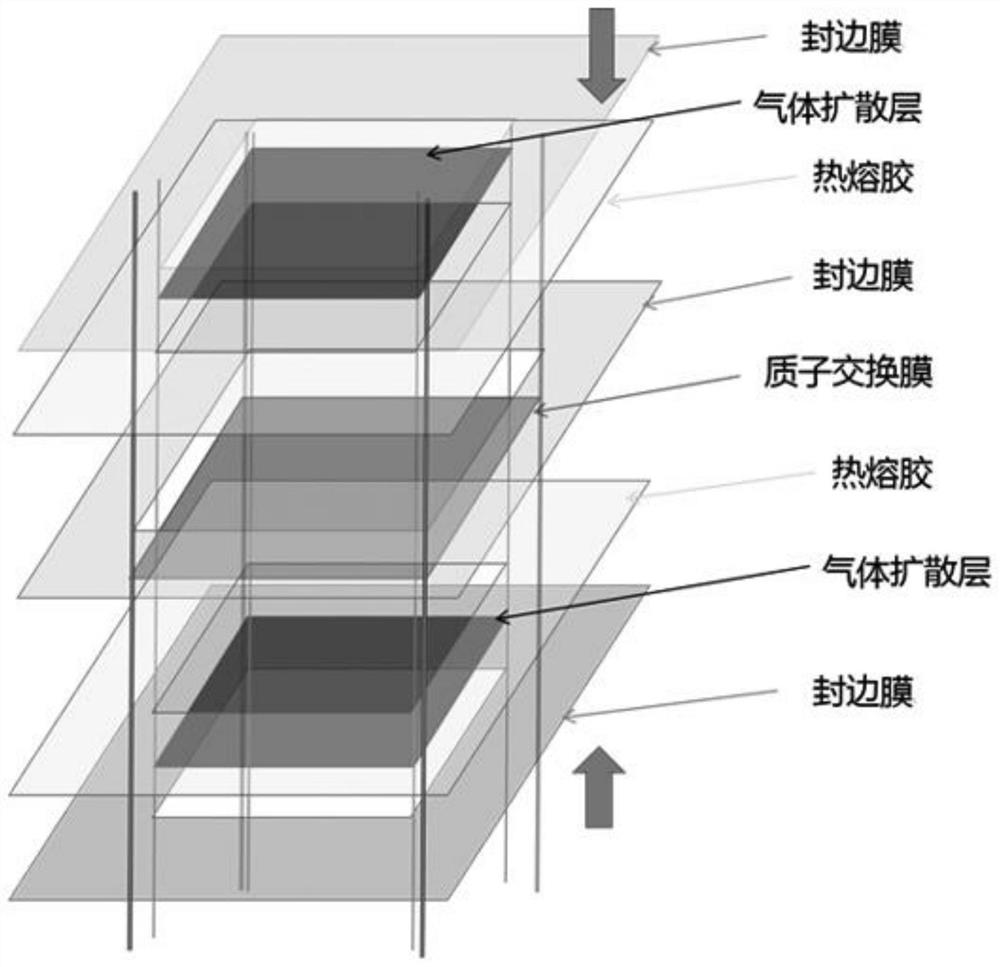

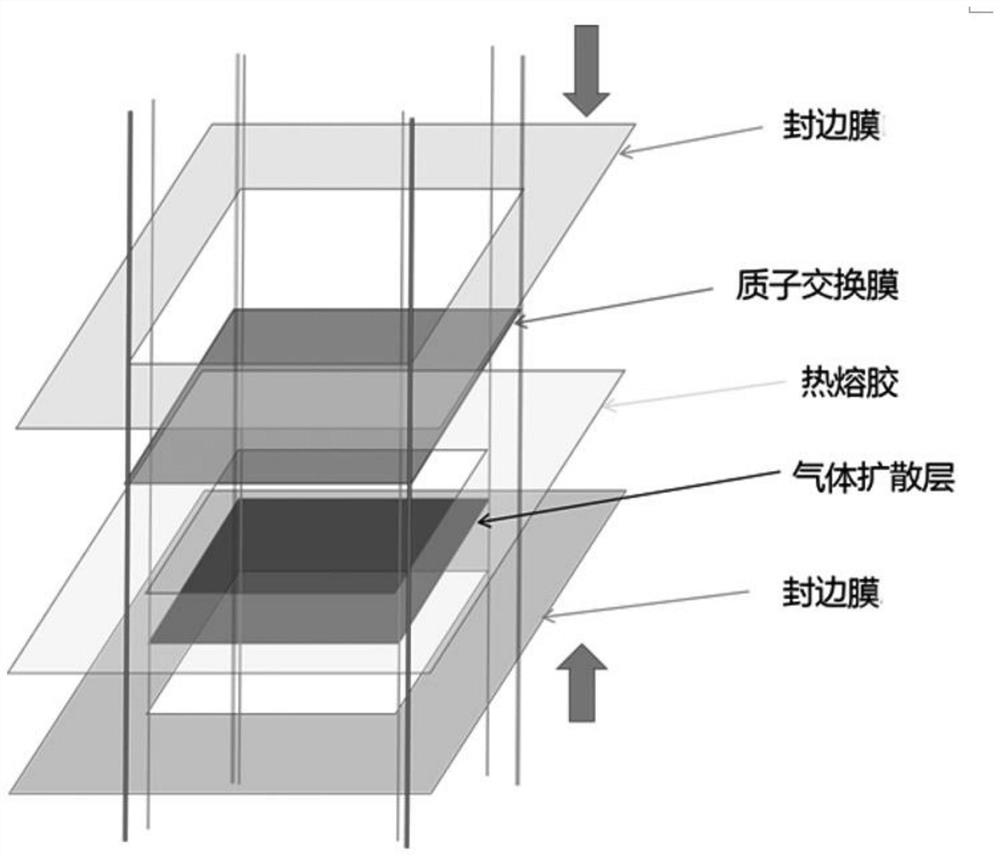

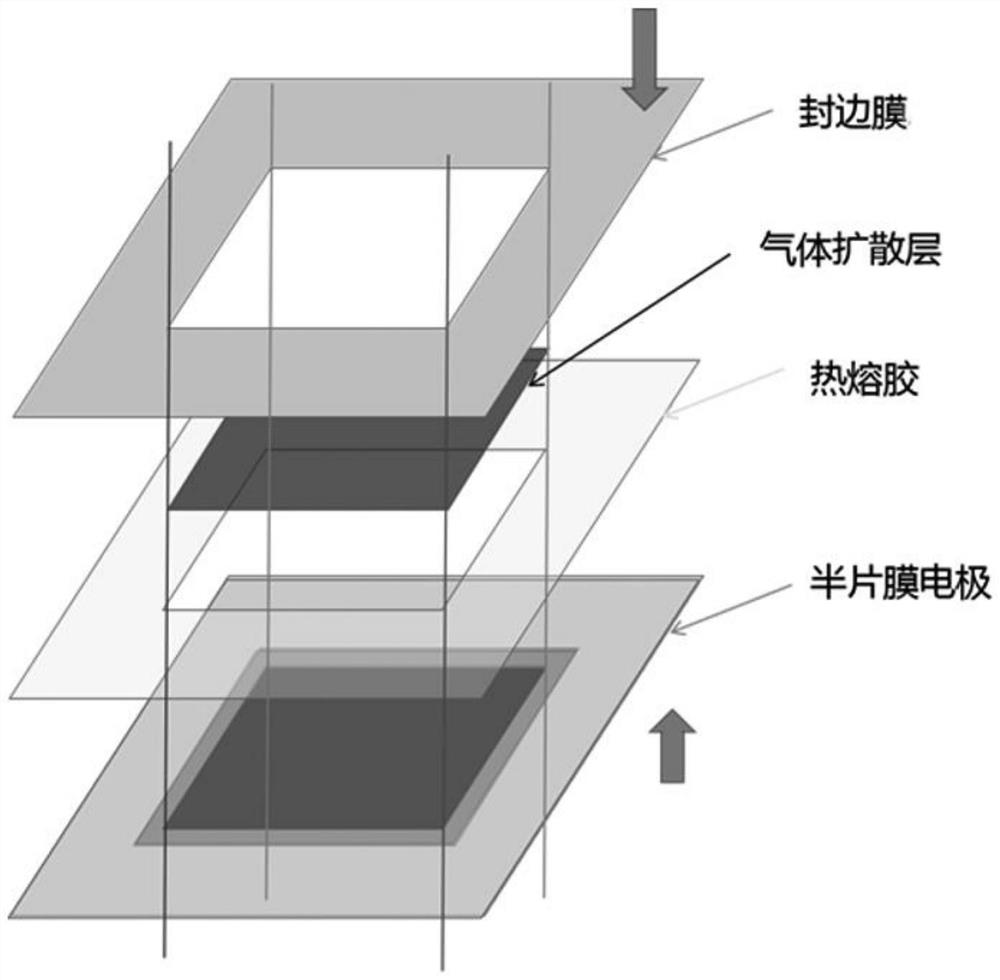

[0021] Step 3. Cut out the proton exchange membrane, two edge-sealing membranes, hot-melt adhesive film and gas diffusion layer respectively. Outer 9*9cm and inner square hole: 5.2*5.2cm, outer 9*9cm), gas diffusion layer (5*5cm), hot melt adhesive (inner square hole 5*5cm, outer 9*9cm);

[0022] Step 4. Put the proton exchange m...

Embodiment 2

[0026] A membrane electrode with an effective active area of 5*5cm is prepared by the method provided by the invention:

[0027] Step 1. First weigh 25 mg of 60% Pt / C catalyst, ultrasonically disperse it in 10 mL of water, then add 5 mL of isopropanol and 3 mL of DMF, stir thoroughly and then cool in an ice bath for ultrasonic dispersion to obtain a solution;

[0028] Step 2. In the isopropanol of 12mL that the 5% Nafion solution of taking 0.2g is added, under ice-bath cooling ultrasonic dispersion condition, to the solution gained in step 1, dropwise add the mixed solution of Nafion and isopropanol, in ice bath Cool and continue ultrasonic dispersion for 1 hour;

[0029] Step 3. Cut out the proton exchange membrane, two edge-sealing membranes, hot-melt adhesive film and gas diffusion layer respectively. Outer 9*9cm and inner square hole: 5.2*5.2cm, outer 9*9cm), gas diffusion layer (5*5cm), hot melt adhesive (inner square hole 5*5cm, outer 9*9cm);

[0030] Step 4. The fro...

Embodiment 3

[0036] A membrane electrode with an effective active area of 15*15cm is prepared by the method provided by the invention:

[0037] Step 1. First weigh 500mg of 40% Pt / C catalyst, ultrasonically disperse it in 100mL of water, then add 50mL of isopropanol and 30mL of DMF, stir thoroughly and then cool in an ice bath for ultrasonic dispersion to obtain a solution;

[0038] Step 2. In the isopropanol of 20mL that the 5% Nafion solution that takes 6g is added, under ice-bath cooling ultrasonic dispersion condition, to step 1 gained solution drop by drop the mixed solution of Nafion and isopropanol, in ice bath Cool and continue ultrasonic dispersion for 1 hour;

[0039] Step 3. Cut out the proton exchange membrane, two edge-sealing membranes, the hot-melt adhesive film and the gas diffusion layer respectively. Outer side 20*16cm and inner square hole: 15.5*15.5cm, outer side 20*16cm), gas diffusion layer (15*15cm), hot melt adhesive (inner square hole 15*15cm, outer side 20*16cm);...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com