Method for determining dimensions of graphite electrode contact based on normal temperature processing and high temperature use

A graphite electrode and size technology, applied in electric heating devices, electrical components, heating by discharge, etc., can solve problems such as bursting, and achieve the effect of reducing loss, avoiding bursting, and achieving remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

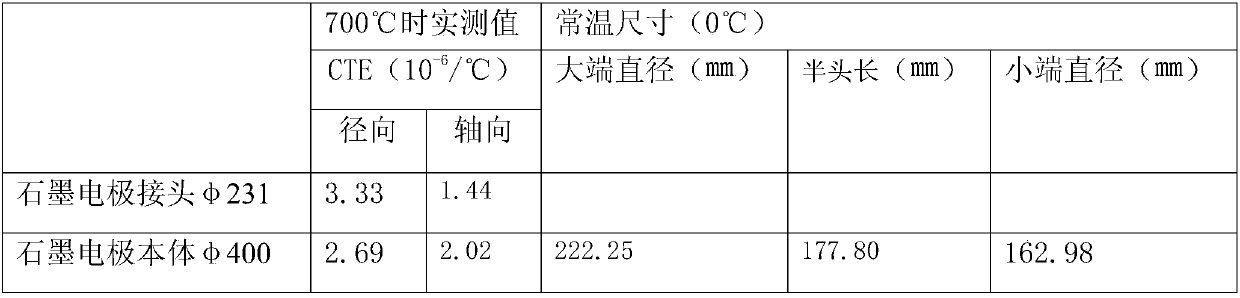

[0026] Embodiment 1, this embodiment is a method for determining the size of graphite electrode joints based on normal temperature processing and high temperature use, using the base hole system, and taking the diameter of the large end or the diameter of the small end or the length of the half end of the graphite electrode body as a benchmark Holes, with the diameter of the large end of the graphite electrode joint or the diameter of the small end or the length of the half head as the matching axis, the size of the graphite electrode body and graphite electrode joint for 400UHP ultra-high power is determined, and the diameter of the graphite electrode body is φ400.00 ㎜, graphite electrode connector hole diameter φ222.25㎜, half head length 177.80㎜, room temperature 0°C, high temperature 700°C, including the following steps: 1) Laboratory measurement of the linear thermal expansion coefficient of graphite electrode body and electrode joint, see Table 1;

[0027] Table 1 Linear ...

Embodiment 2

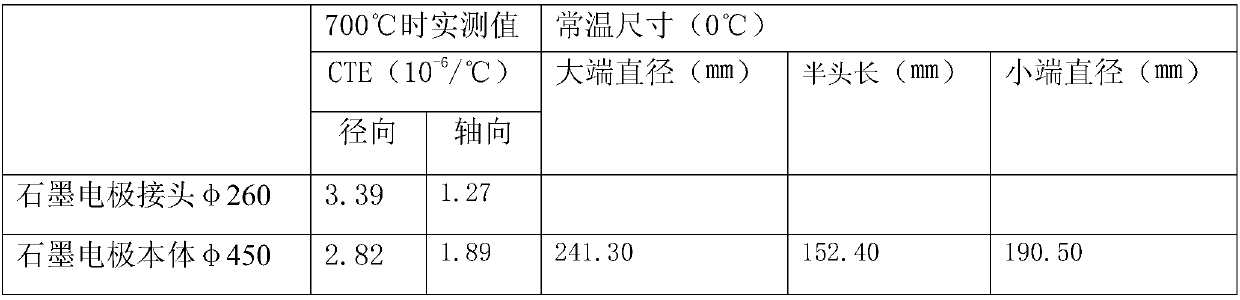

[0041] Embodiment 2, this embodiment is a method for determining the size of graphite electrode joints based on normal temperature processing and high temperature use. The base hole system is adopted, and the diameter of the large end or the diameter of the small end or the length of the half end of the graphite electrode body is used as a benchmark The diameter of the large end of the graphite electrode connector or the diameter of the small end or the length of the half head is used as the matching axis. The size of the graphite electrode body and the graphite electrode connector for 450UHP is determined. The diameter of the graphite electrode body is φ450.00㎜, and the graphite electrode body The diameter of the electrode joint hole is φ241.30㎜, the half-head length is 152.40㎜, the normal temperature is 0°C, and the high temperature is 700°C, including the following steps:

[0042] 1) The laboratory measures the linear thermal expansion coefficient of the graphite electrode b...

Embodiment 3

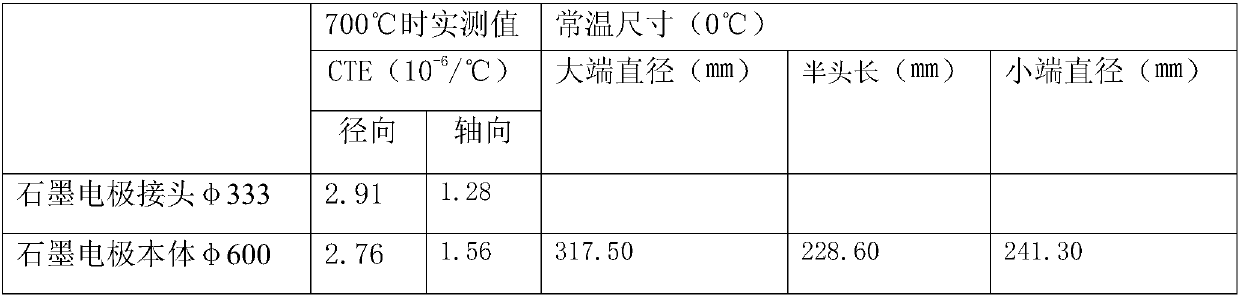

[0057] Embodiment 3, this embodiment is a method for determining the size of graphite electrode joints based on normal temperature processing and high temperature use. The base hole system is adopted, and the diameter of the large end or the diameter of the small end or the length of the half end of the graphite electrode body is used as a benchmark Holes, with the diameter of the large end of the graphite electrode joint or the diameter of the small end or the length of the half head as the matching axis, the size of the graphite electrode body and graphite electrode joint used for 600UHP is determined, the diameter of the graphite electrode body is φ600.00㎜, graphite The diameter of the electrode joint hole is φ317.5.00㎜, the half-head length is 228.60㎜, the normal temperature is 0°C, and the high temperature is 700°C. The processing is based on the joint hole of the graphite electrode body, including the following steps:

[0058] 1) The laboratory measures the linear thermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com