A kind of pulverized coal forming dry distillation method with tar residue as base binder

A technology of tar residue and adhesive, applied in the field of coal chemical industry, can solve the problems of reducing the potential value of coal tar and low recovery rate of coal tar, and achieve the effects of alleviating the shortage of coal resources, good bonding performance and high oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

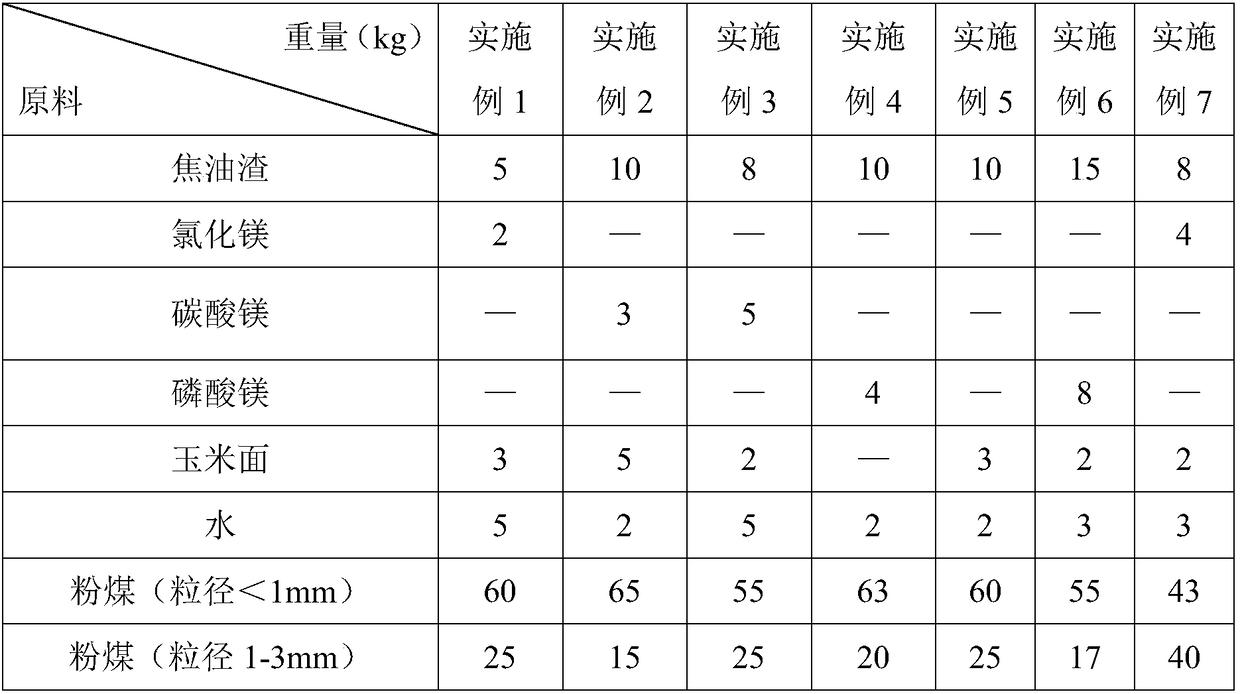

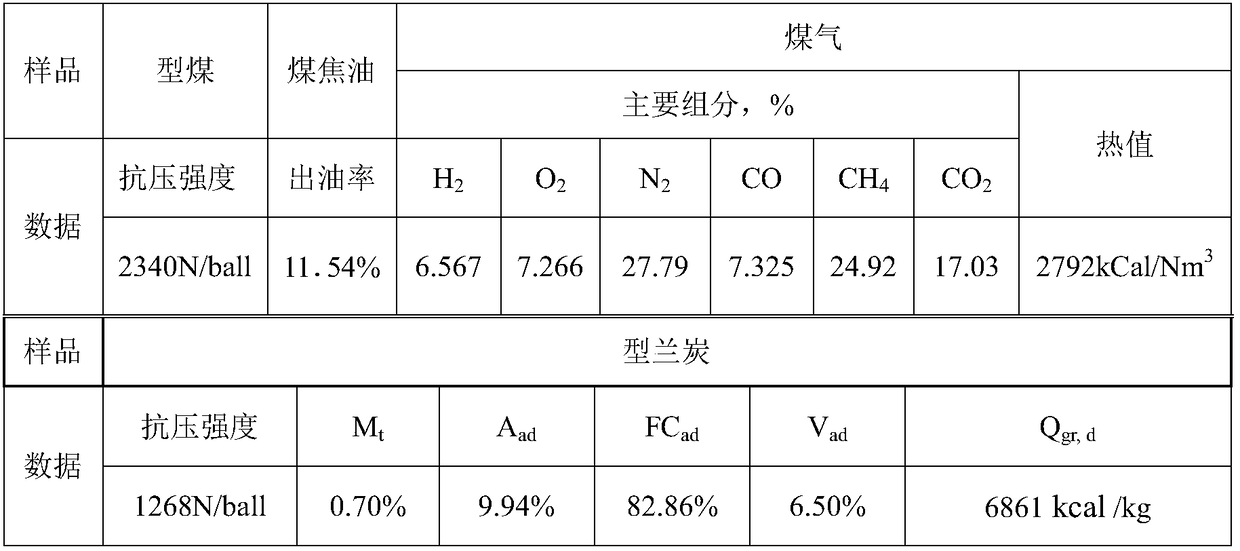

[0028] Take 5kg of tar residue, 2kg of magnesium chloride, 3kg of cornmeal, 60kg of pulverized coal with a particle size of 1mm or less, 25kg of pulverized coal with a particle size of 1-3mm, and 5kg of water. After drying for 28 hours, dry distillation at 750°C for 2 hours to obtain semi-coke, coal tar and gas. Table 3 shows the performance analysis of briquettes and the briquettes obtained after dry distillation of briquettes, coal tar and gas.

[0029] The briquette that table 3 embodiment 1 obtains and briquette charcoal, coal tar, gas performance analysis result obtained after dry distillation of briquette

[0030]

[0031] In the table: Q gr,d High calorific value on a dry basis.

[0032] As can be seen from Table 3, the blue coke strength, the oil yield of coal tar, and the gas calorific value are greatly improved after the dry distillation of Example 1, and the obtained air-dry base ash content and air-dry base volatile matter are within a certain range, avoiding ...

Embodiment 2

[0034] Get 10kg of tar residue, 3kg of magnesium carbonate, 5kg of cornmeal, 65kg of pulverized coal with a particle size of 1mm or less, 15kg of pulverized coal with a particle size of 1mm to 3mm, and 2kg of water. After natural drying for 24 hours, dry distillation at 550°C for 4 hours. Table 3 shows the performance analysis of briquettes and the briquettes obtained after dry distillation of briquettes, coal tar and gas.

[0035] The briquette that table 4 embodiment 2 obtains and briquette charcoal, coal tar, gas property analysis result that obtain after dry distillation of briquette

[0036]

[0037] In the table: Q gr,d High calorific value on a dry basis.

[0038] As can be seen from Table 4, the blue coke strength, the oil yield of coal tar, and the gas calorific value are greatly improved after the dry distillation of Example 2, and the obtained air-dry base ash content and air-dry base volatile matter are within a certain range, avoiding It eliminates the pollu...

Embodiment 3

[0040] Get 8kg of tar residue, 5kg of magnesium sulfate, 2kg of cornmeal, 55kg of pulverized coal with a particle size of 1mm or less, 25kg of pulverized coal with a particle size of 1mm to 3mm, and 5kg of water, stir and mix evenly, and pressurize at 8MPa to obtain briquettes. After natural drying for 36 hours, dry distillation at 650°C for 4 hours. Table 4 shows the performance analysis of the briquettes and the briquettes, coal tar, and gas obtained after dry distillation of the briquettes.

[0041] The briquette that table 5 embodiment 3 obtains and briquette charcoal, coal tar, gas property analysis result that obtain after carbonization of briquette

[0042]

[0043] In the table: Q gr,d High calorific value on a dry basis.

[0044] As can be seen from Table 5, the blue coke strength, the oil yield of coal tar, and the gas calorific value are greatly improved after dry distillation in Example 1, and the obtained air-dry base ash content and air-dry base volatile mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com