Heat exchanger used for high-pressure freezing type compressed air dryer

A compressed air and refrigerated technology, which is applied in refrigerators, dry solid materials, evaporators/condensers, etc., can solve the problems of difficult processing, difficult to guarantee safety, and long cycle, so as to reduce processing cycle and cost, Easy to purchase, make and assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The present invention is not limited to this embodiment, and other embodiments may also belong to the scope of the present invention as long as they conform to the gist of the present invention.

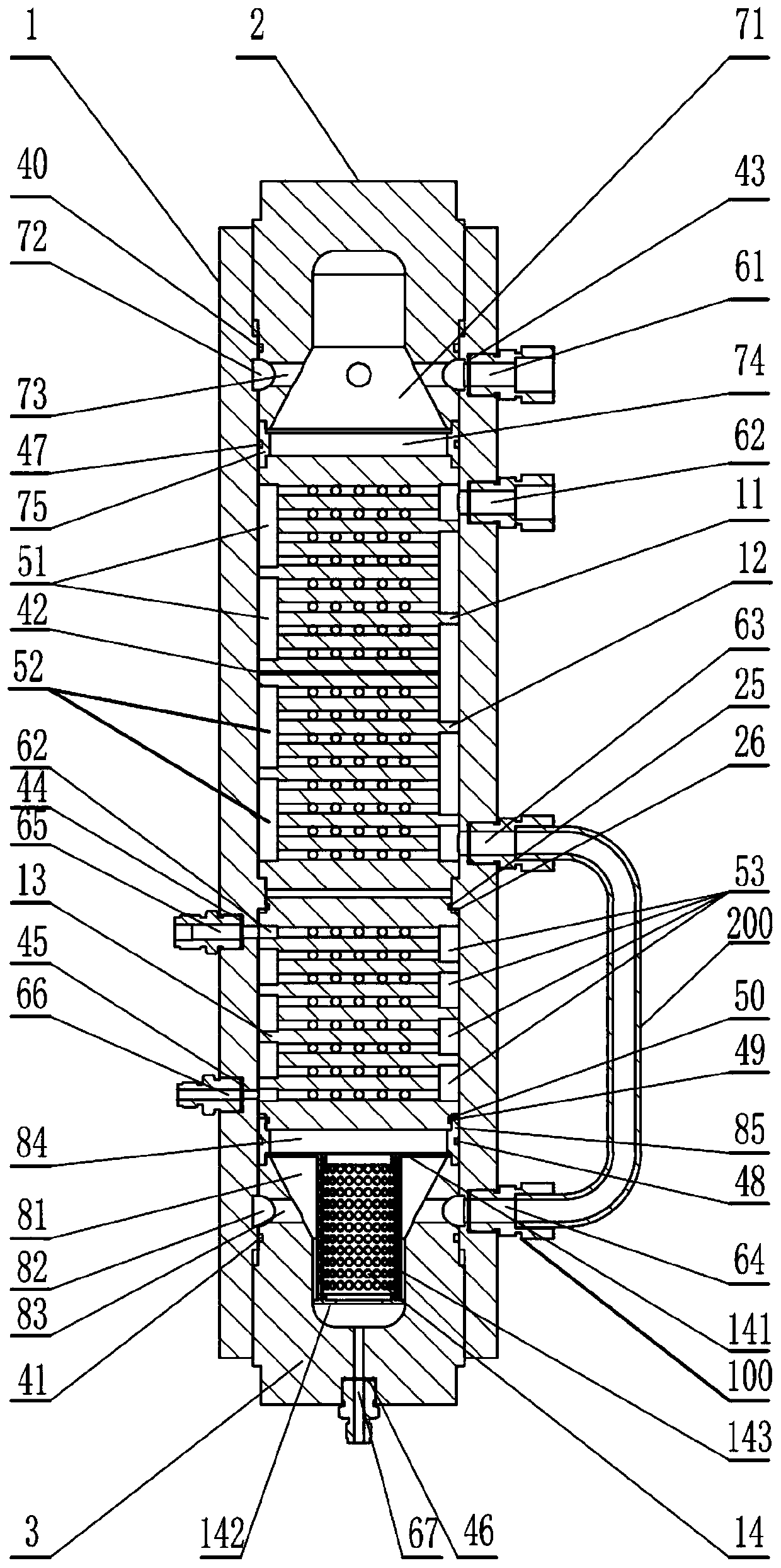

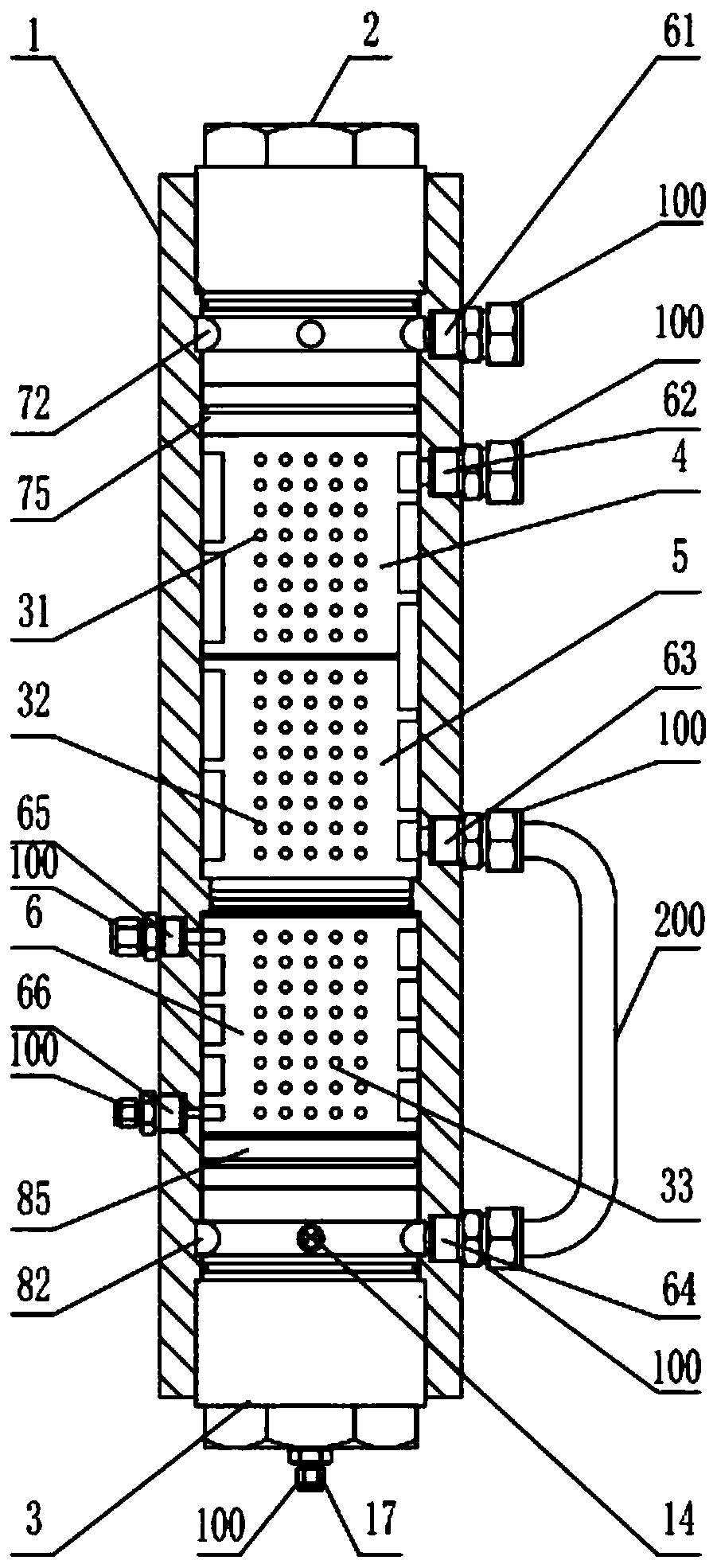

[0051] In a preferred embodiment of the present invention, based on the above-mentioned problems existing in the prior art, a heat exchanger for a high-pressure refrigerated compressed air dryer is now provided, such as figure 1 with figure 2 shown, including:

[0052] Cylindrical housing 1, the top of cylindrical housing 1 is provided with an upper cover 2 that is threadedly connected with cylindrical housing 1, and the bottom end of cylindrical housing 1 is provided with cylindrical housing The lower cover 3 of the body 1 threaded connection;

[0053] A first O-ring 40 is radially sealed between the upper cover 2 and the inner wall of the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com