Compression-resistant and expansion-crack-resistant rubber pipeline

A rubber pipeline, anti-swell technology, used in pipeline protection, pipeline damage/wear prevention, hoses, etc., can solve problems such as pressure rupture, stagnation of liquid transportation, pipeline blockage, etc., to speed up dredging efficiency and prevent swelling and cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

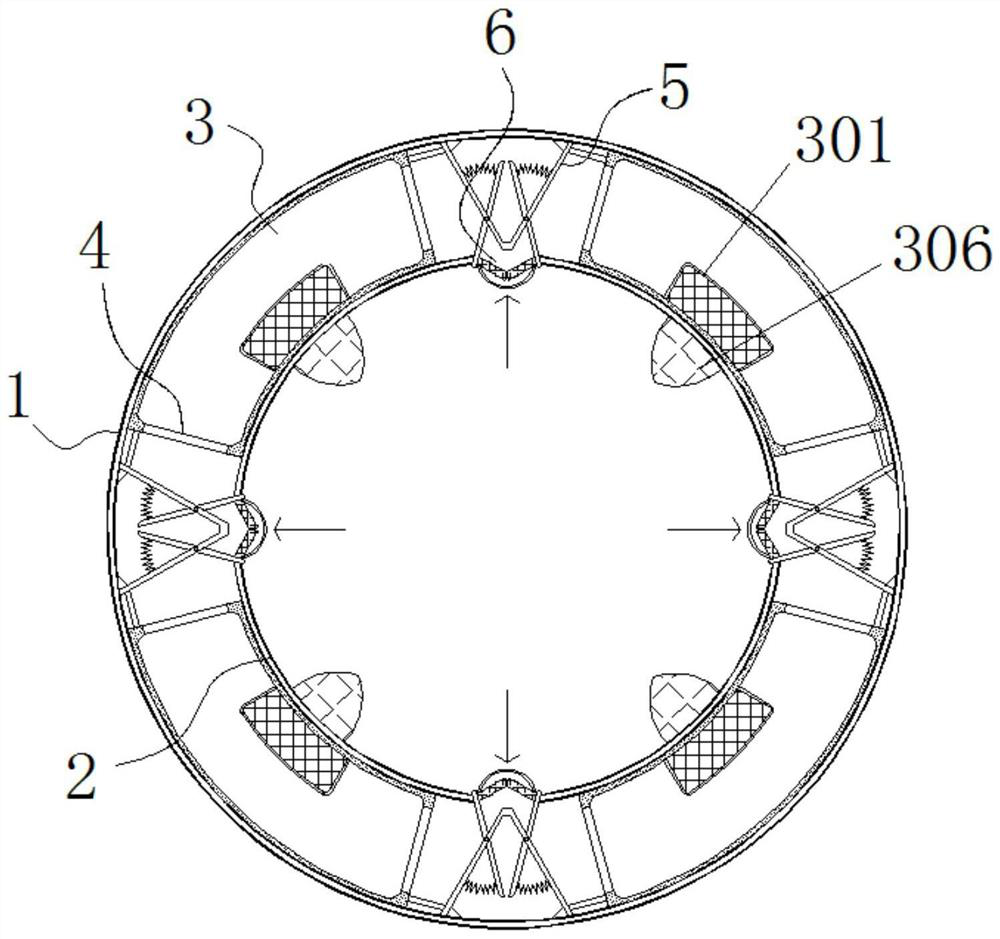

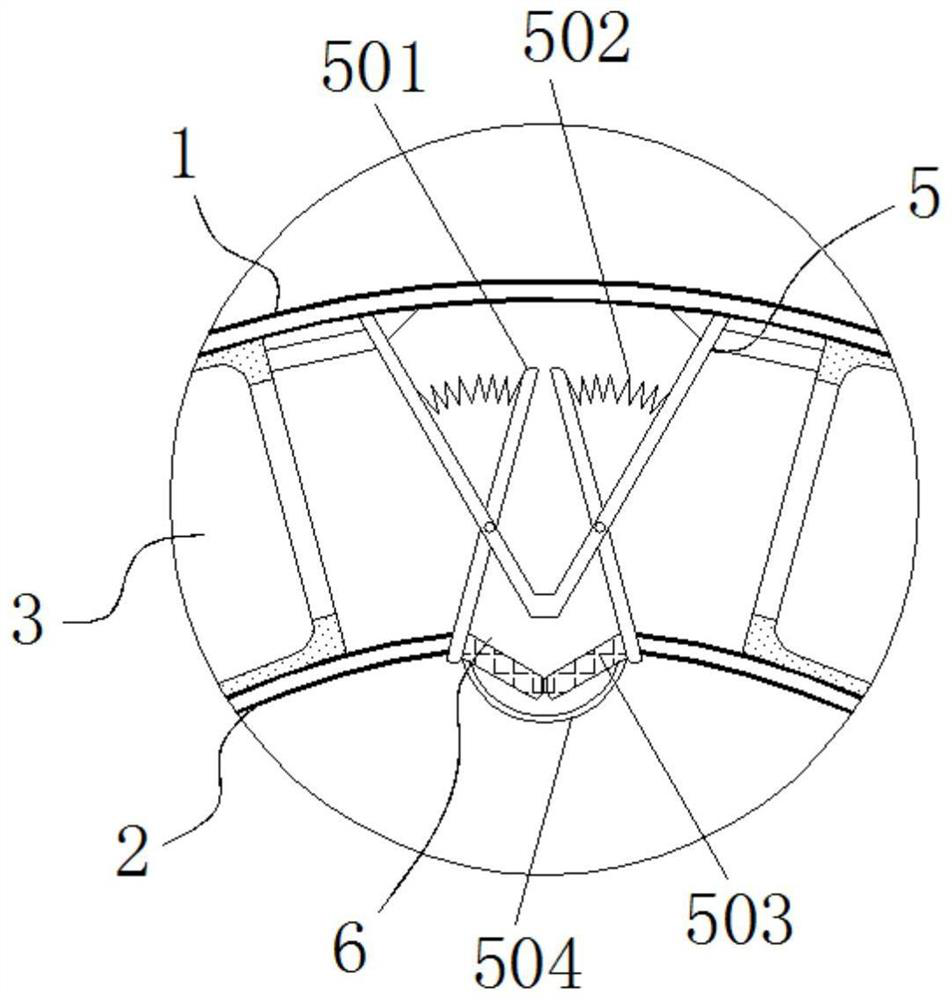

[0047] see Figure 1-3 and Figure 6-9 , the present invention provides a kind of technical scheme:

[0048] A compressive and anti-expansion-resistant rubber pipe, comprising:

[0049] The outer attached pipe 1 is provided with an inner lining pipe 2 on its inner side, and a reinforced pipe 3 is equiangularly distributed in the reserved pores between the inner lined pipe 2 and the outer attached pipe 1, and the outer side wall of the reinforced pipe 3 is connected to the inner lining pipe. 2 and the externally attached pipe 1 are both fixedly connected, and the reinforcing pipe 3 is arranged in an arc shape;

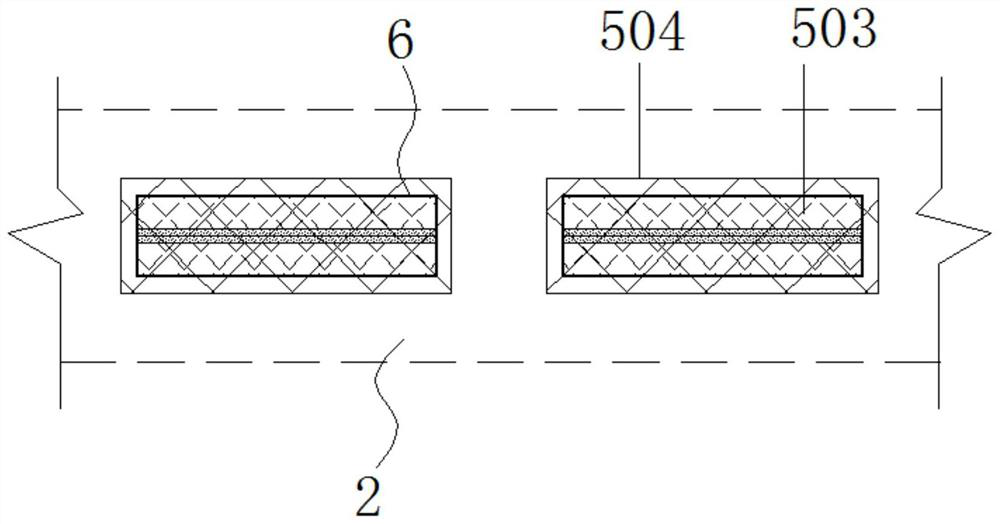

[0050] according to figure 1 and Figure 6-9 In the technical solution shown, net pockets 301 are fixed inside the reinforcing tube 3, and the net pockets 301 are located between the guide holes 7. Each group of guide holes 7 is arranged in a one-to-one correspondence with the net pockets 301, and the inside of the net pockets 301 is rotated and installed. There is...

Embodiment 2

[0059] see figure 1 and Figure 4-9 , the present invention provides a kind of technical scheme:

[0060] A compressive and anti-expansion-resistant rubber pipe, comprising:

[0061] The outer attached pipe 1 is provided with an inner lining pipe 2 on its inner side, and a reinforced pipe 3 is equiangularly distributed in the reserved pores between the inner lined pipe 2 and the outer attached pipe 1, and the outer side wall of the reinforced pipe 3 is connected to the inner lining pipe. 2 and the externally attached pipe 1 are both fixedly connected, and the reinforcing pipe 3 is arranged in an arc shape;

[0062] according to figure 1 and Figure 6-9 In the technical solution shown, net pockets 301 are fixed inside the reinforcing tube 3, and the net pockets 301 are located between the guide holes 7. Each group of guide holes 7 is arranged in a one-to-one correspondence with the net pockets 301, and the inside of the net pockets 301 is rotated and installed. There is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com