Method for improving biofilm culturing efficiency and application thereof

A biofilm reactor and biofilm technology, which is applied in biological treatment devices, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of long time for acclimation and cultivation of low-temperature microorganisms, increased treatment costs, and easy shedding adaptability. , to achieve the effect of easy engineering promotion and application, fast film hanging speed, and not easy to remove film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present embodiment provides a kind of method that improves biofilm hanging film efficiency, specific content is as follows:

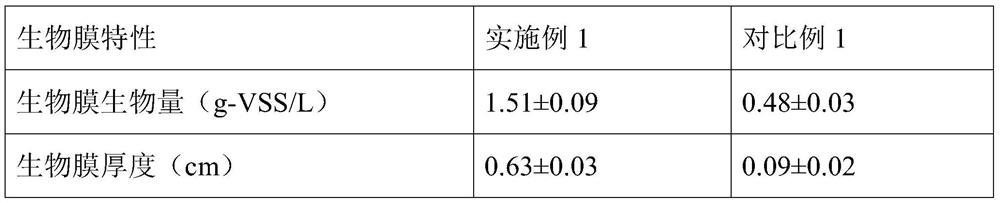

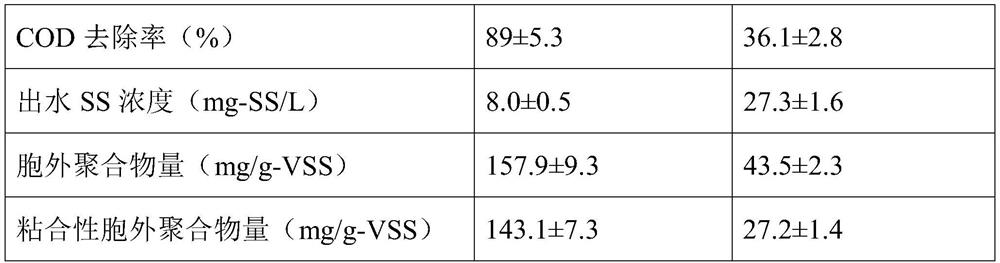

[0037]Adopt the method for the present invention to start co-rotating mass transfer biofilm-moving bed biofilm reactor (MBBR) to start film formation, at first the aerobic activated sludge that 1600mL concentration is 2500mg-VSS / L is inoculated in the MBBR system (effective The volume is 3.2L, semi-soft packing (polypropylene, Φ120, Jiangsu Nantai Environmental Protection Packing Co., Ltd.), 30% filling degree), the influent is municipal wastewater, the influent COD concentration is 410mg-COD / L, hydraulic retention The time (HRT) is 6h, the organic load of the reactor water is 0.41g-COD / (g-VSS·d), the stirring rate in the reactor is controlled at 120rpm, and the oxygen supply is provided by a microporous aerator to maintain the dissolved oxygen concentration (DO) is 2-4mg / L (DO fluctuates within the range of 2-4mg / L during operation), and the...

Embodiment 2

[0047] The present embodiment provides a kind of method that improves biofilm hanging film efficiency, specific content is as follows:

[0048] Adopt method of the present invention to start the same direction mass transfer anaerobic biofilm-anaerobic contact oxidation tank starts to hang film, at first 6L concentration is the digester sludge that 3500mg-VSS / L is inoculated in the anaerobic contact oxidation tank (effective volume 4.5m 3 , elastic filler (YCDT type, Jiangsu Nantai Environmental Protection Filling Co., Ltd.), 45% filling degree), the influent is methyl methacrylate MMA chemical wastewater, and the COD concentration of the raw water is 6000mg-COD / L. In this case, the influent COD concentration is 1500mg-COD / L, and the hydraulic retention time (HRT) is 6.7h. At this time, the influent organic load (OLR) of the reactor is 0.26g-COD / (g-VSS·d), and the reaction The stirring rate in the vessel is controlled at 120rpm, the pH range is 6.8-7.4 (the pH value fluctuates...

Embodiment 3

[0057] The present embodiment provides a kind of method that improves biofilm hanging film efficiency, specific content is as follows:

[0058] Adopt the method described in the present invention to start heterotropic mass transfer biofilm MABR to start hanging film, at first 500mL concentration is the secondary settling tank activated sludge of 3000mg-VSS / L to inoculate in the MABR system (effective volume is 1.54L, membrane module ratio Surface area is 84.5m 2 / m 3 ), the influent is toxic and difficult-to-treat acetonitrile (ACN) wastewater, its concentration is 314mg-ACN / L, and the corresponding COD concentration is 500mg-COD / L. At this time, the organic load (OLR) of the reactor is 0.32g-COD / ( g-VSS d), the rising flow rate in the reactor is controlled at 2.5cm / s, under the transmembrane oxygen partial pressure of 22-28kPa, with 14-17mL-O 2 The flow rate of / min provides bubble-free aeration to maintain the liquid phase dissolved oxygen (DO) concentration at 1.5-3mg / L (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com