A kind of zn-mg two-phase heterogeneous material and preparation method thereof

A zn-mg, different technology, applied in the direction of prosthesis, surgery, tissue regeneration, etc., can solve the problem of obvious stress shielding effect and high elastic modulus, achieve obvious advantages of healing structure strength, increase new bone mass, avoid localization swelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Preparation of Zn-Mg dual-phase heterogeneous material by variable temperature accumulative rolling + recrystallization gap annealing

[0021] The preparation process route is: laminated billets→variable temperature accumulative stack rolling→recrystallization gap annealing→deep processing into devices. The specific instructions are as follows:

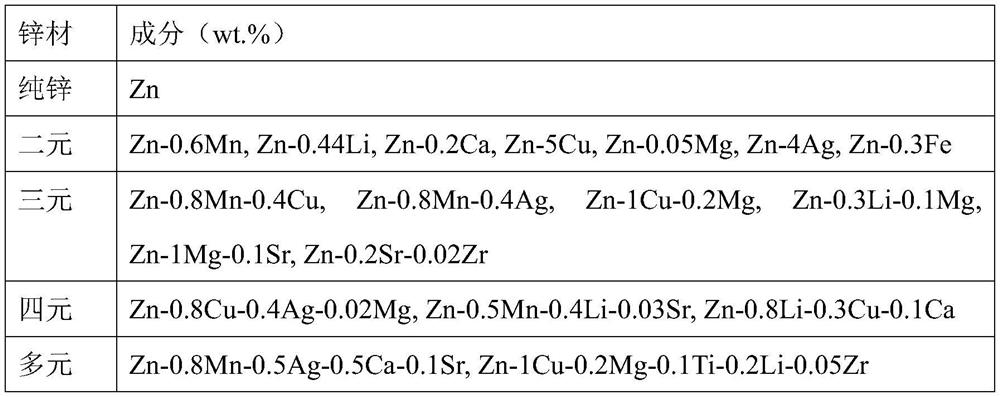

[0022] (1) Stacked blanks: First, mechanically polish the 0.5-10mm thick zinc plate (see Table 1-1 for composition) and 0.1-2mm thick magnesium plate (see Table 1-2 for composition) to obtain a clean surface, and then Fold them together, wrap and seal with aluminum foil.

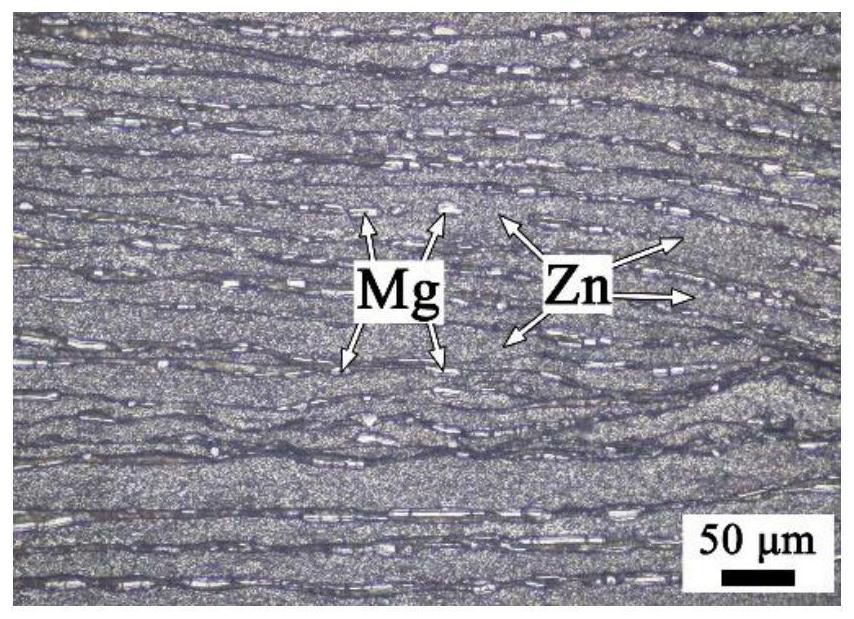

[0023] (2) Variable-temperature accumulative stack rolling: heat the above-mentioned billets at 320-380° C. for 1-30 minutes, and then carry out the first rolling pass, with the reduction of each pass being 40%-80%. Cut the obtained Zn / Mg composite plate from the middle into two plates of equal length, mechanically polish the surface, stack and f...

Embodiment 2

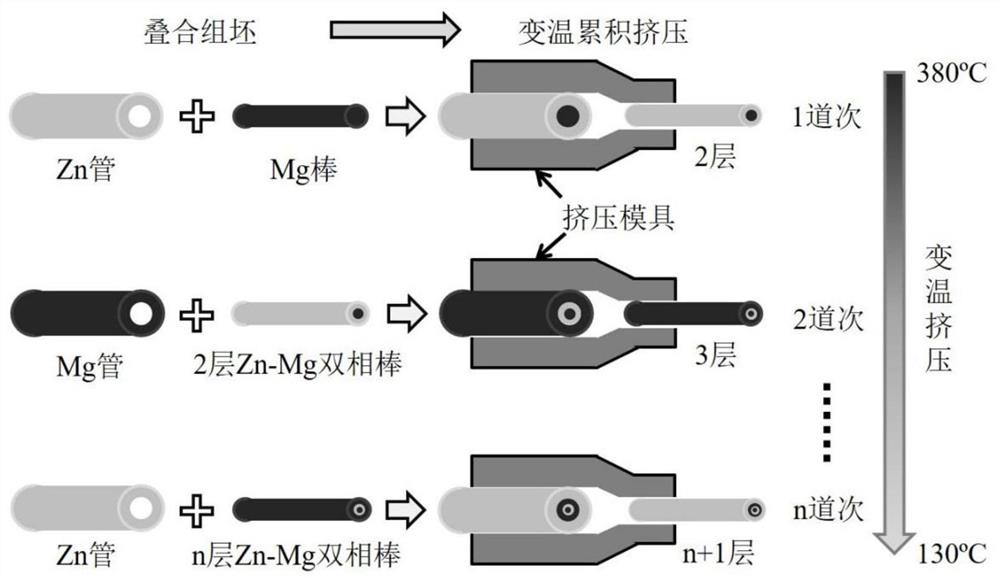

[0030]Example 2: Preparation of Zn-Mg dual-phase heterogeneous material by variable temperature accumulative extrusion + recrystallization gap annealing

[0031] The preparation process route is: laminated billets→variable temperature accumulative extrusion→recrystallization gap annealing→deep processing into devices. The specific instructions are as follows:

[0032] (1) Stacked billets: pickling all Zn and Mg rods and pipes before stacking billets to obtain a clean surface. The center is a Mg rod with a diameter of 5-10mm, and zinc tubes with a wall thickness of 1-5mm are laminated in the order from the core to the outer layer Mg / Zn / Mg / Zn... (see Table 1-1 for composition) and Magnesium tubes with a wall thickness of 0.1 to 1 mm (see Table 1-2 for composition) form a multi-layer ring sleeve assembly. The number of layers of the multi-layer ring sleeve assembly is 2 to 10 layers.

[0033] (2) Accumulative extrusion with variable temperature: The above-mentioned billets are...

Embodiment 3

[0036] Embodiment 3: Performance test of Zn-Mg two-phase heterogeneous material and its comparison material

[0037] Performance tests were performed on the Zn-Mg biphasic heterogeneous materials prepared in Examples 1 and 2. Tensile samples were prepared according to the national standard GB / T228.1-2010 "Metallic Materials Tensile Test Part 1, Room Temperature Test Method", and the measured yield strength was >250MPa, tensile strength >300MPa, and elongation >20%. The hardness measured by the Vickers hardness tester model HV-1000 is >80HV. According to American Standard ASTM G31-2012 "Standard Guide for Laboratory Immersion Corrosion Testing of Metals", the degradation rate of the material in Hank's solution at 37°C is 30-500 μm / year. According to the national standard GB / T 22315-2008 "Metallic Materials. Elastic Modulus and Poisson's Ratio Test Method", the elastic modulus is 60-90GPa. The alloy extract was prepared according to the national standard GB / T16886.5-2017 "Biol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com