Fiber composite material crossed rib thin laying layer and preparation method thereof

A fiber composite material and rib technology, which is applied in the field of composite material structure design and preparation, can solve the problems of local macro uplift in the overlapping area and the reduction of stress concentration and axial bearing capacity at the same time, so that the axial bearing performance will not decrease. , to avoid the effect of local bulge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

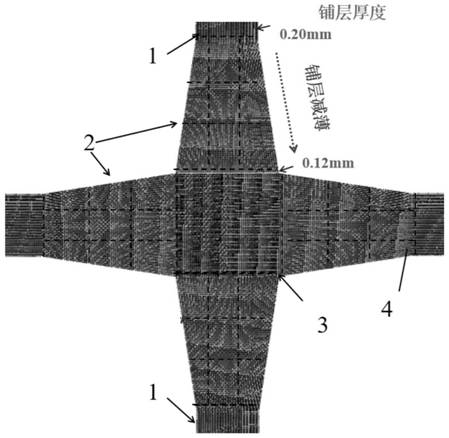

[0034] This embodiment provides a rib cross-lamination and a preparation method thereof, comprising the following steps:

[0035] S1: laying the rib end area, the intersection area and the transition area between the two end areas and the intersection area, specifically including:

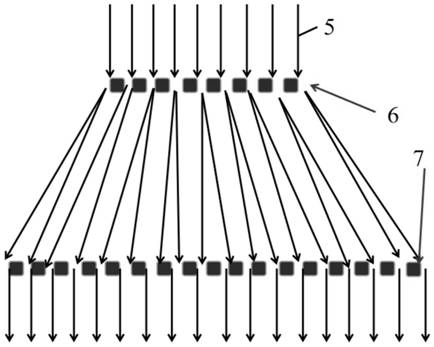

[0036] S11. Place a comb-toothed mold at both ends of the transition zone of the ribs. The structural diagram of the comb-toothed mold is as follows figure 2 As shown, the comb-toothed mold includes a first comb-toothed mold 6 and a second comb-toothed mold 7, wherein the first comb-toothed mold is located at one end of the transition zone (such as figure 2 In 6), there are 8 comb teeth, the distance between adjacent teeth is 2 (mm), and the remaining comb teeth are arranged in parallel at the other end of the transition zone, with 17 comb teeth, and the distance between adjacent teeth is 2 (mm);

[0037] S12. Laying several fibers crosswise, the fibers are oriented in parallel at both ends of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com