Zn-Mg biphasic heterogeneous material and preparation method thereof

A zn-mg, dissimilar technology, applied in the field of Zn-Mg biphasic heterogeneous materials and its preparation, can solve the problems of high elastic modulus and obvious stress shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Preparation of Zn-Mg dual-phase heterogeneous material by variable temperature accumulative rolling + recrystallization gap annealing

[0021] The preparation process route is: laminated billets→variable temperature accumulative stack rolling→recrystallization gap annealing→deep processing into devices. The specific instructions are as follows:

[0022] (1) Stacked blanks: First, mechanically polish the 0.5-10mm thick zinc plate (see Table 1-1 for composition) and 0.1-2mm thick magnesium plate (see Table 1-2 for composition) to obtain a clean surface, and then Fold them together, wrap and seal with aluminum foil.

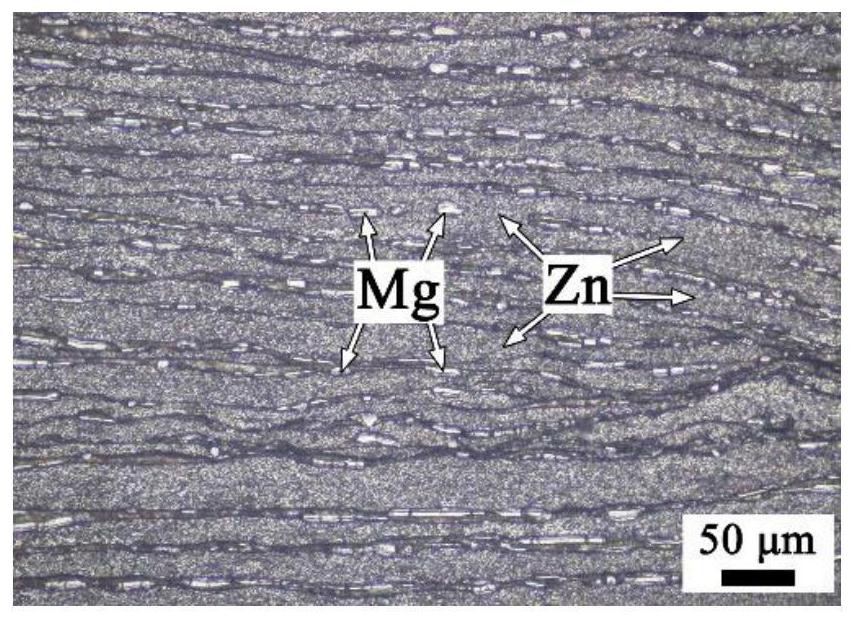

[0023] (2) Variable-temperature accumulative stack rolling: heat the above-mentioned billets at 320-380° C. for 1-30 minutes, and then carry out the first rolling pass, with the reduction of each pass being 40%-80%. Cut the obtained Zn / Mg composite plate from the middle into two plates of equal length, mechanically polish the surface, stack and f...

Embodiment 2

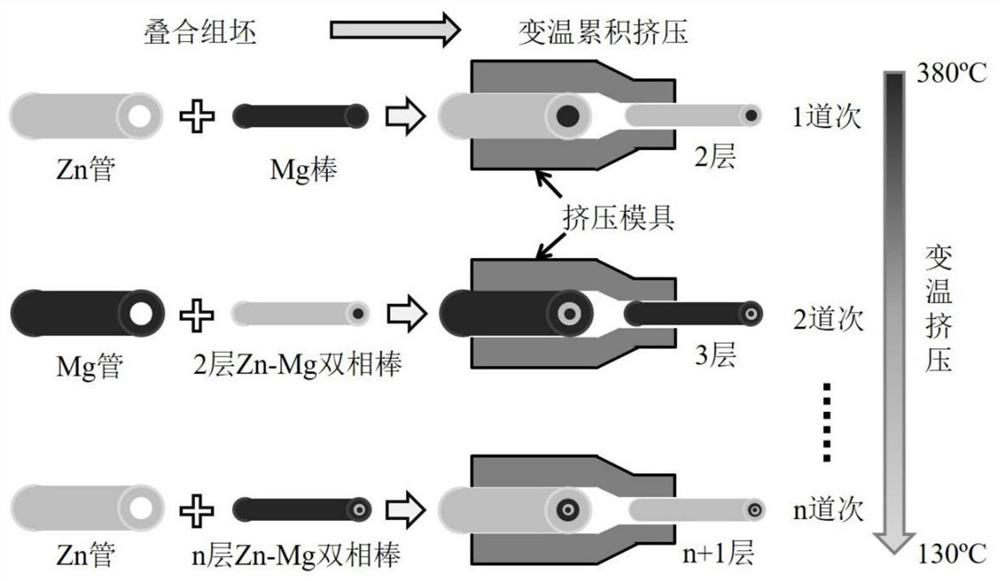

[0030]Example 2: Preparation of Zn-Mg dual-phase heterogeneous material by variable temperature accumulative extrusion + recrystallization gap annealing

[0031] The preparation process route is: laminated billets→variable temperature accumulative extrusion→recrystallization gap annealing→deep processing into devices. The specific instructions are as follows:

[0032] (1) Stacked billets: pickling all Zn and Mg rods and pipes before stacking billets to obtain a clean surface. The center is a Mg rod with a diameter of 5-10mm, and zinc tubes with a wall thickness of 1-5mm are laminated in the order from the core to the outer layer Mg / Zn / Mg / Zn... (see Table 1-1 for composition) and Magnesium tubes with a wall thickness of 0.1 to 1 mm (see Table 1-2 for composition) form a multi-layer ring sleeve assembly. The number of layers of the multi-layer ring sleeve assembly is 2 to 10 layers.

[0033] (2) Accumulative extrusion with variable temperature: The above-mentioned billets are...

Embodiment 3

[0036] Embodiment 3: Performance test of Zn-Mg two-phase heterogeneous material and its comparison material

[0037] Performance tests were performed on the Zn-Mg biphasic heterogeneous materials prepared in Examples 1 and 2. Tensile samples were prepared according to the national standard GB / T228.1-2010 "Metallic Materials Tensile Test Part 1, Room Temperature Test Method", and the measured yield strength was >250MPa, tensile strength >300MPa, and elongation >20%. The hardness measured by the Vickers hardness tester model HV-1000 is >80HV. According to American Standard ASTM G31-2012 "Standard Guide for Laboratory Immersion Corrosion Testing of Metals", the degradation rate of the material in Hank's solution at 37°C is 30-500 μm / year. According to the national standard GB / T 22315-2008 "Metallic Materials. Elastic Modulus and Poisson's Ratio Test Method", the elastic modulus is 60-90GPa. The alloy extract was prepared according to the national standard GB / T16886.5-2017 "Biol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com