UV-cured hot-melt acrylate pressure-sensitive adhesive and electrical adhesive tape prepared from same

An acrylate, curing heat technology, applied in the field of pressure-sensitive adhesives, can solve the problems of residual photoinitiator, poor polymer compatibility, easy aging and yellowing of cured products, etc., to reduce the interaction and improve the initial viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

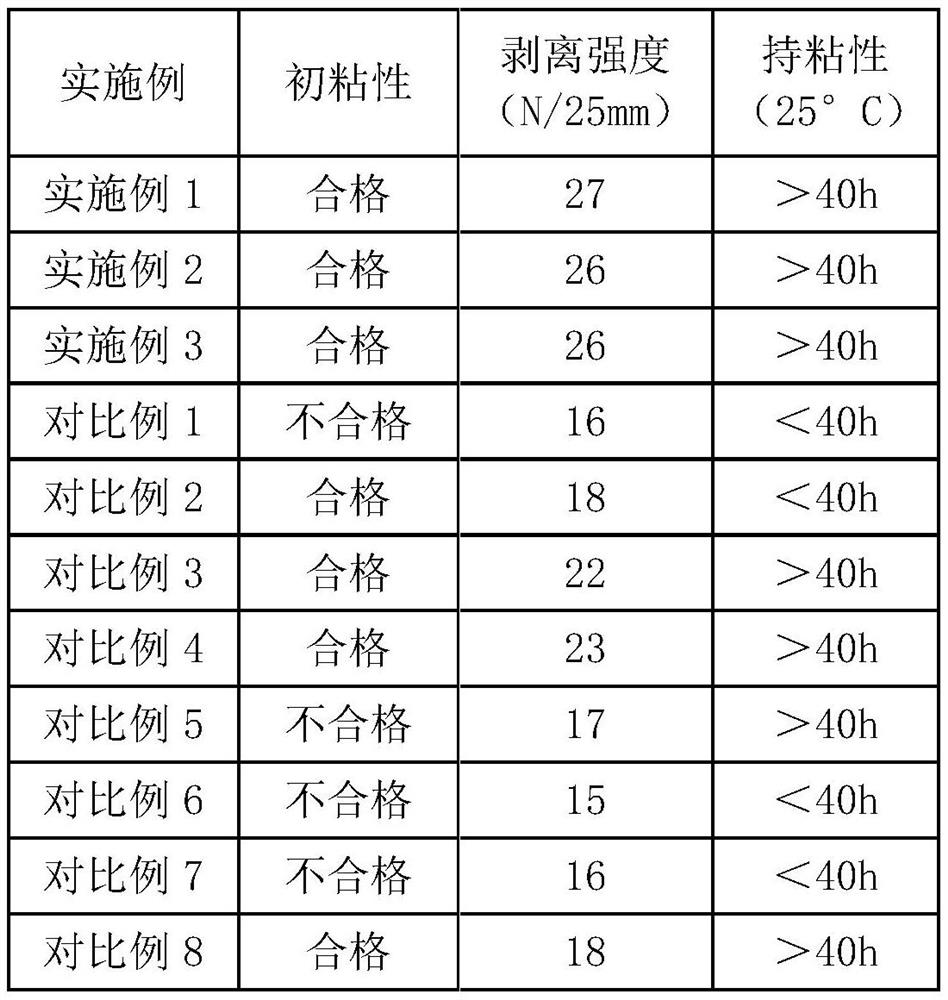

Examples

preparation example Construction

[0030] The preparation method of described macromolecular weight photoinitiator is as follows:

[0031] Equimolar amounts of 4-hydroxybenzophenone, MDI, and 2-hydroxyethyl acrylate were respectively prepared into toluene solutions with a mass fraction of 50%. At 70-80°C, add the toluene solution of MDI into a three-necked flask placed in a constant temperature water bath, protect it with nitrogen, and add dibutyltin dilaurate (accounting for 0.4% of the total amount of reactants) drop by drop at an appropriate stirring speed. ) of 4-hydroxybenzophenone in toluene. Dropping is completed in about 1h. Then the temperature was increased by 10° C., and a toluene solution of 2-hydroxyethyl acrylate was added dropwise. Dropping is completed in about 1h. After cooling down to room temperature, the material is discharged and dried to obtain the polymerizable large molecular weight photoinitiator. Store the synthesized UV curing agent in a dry airtight container away from light.

...

Embodiment 1

[0051] Example 1 provides a UV-curable hot-melt acrylate pressure-sensitive adhesive. The raw materials for its preparation include 40 parts of acrylic resin, 30 parts of tackifying resin, 7 parts of reactive diluent, and 7 parts of ethylenic monomer in parts by weight. 6 parts of softener, 1 part of antioxidant.

[0052] The acrylic resin is polymerized from 80 parts of acrylic acid, 15 parts of vinyl acetate and 0.5 part of initiator.

[0053] The photoinitiator is a polymerizable large molecular weight photoinitiator, and its preparation raw materials include: 4-hydroxybenzophenone, MDI, and 2-hydroxyethyl acrylate. The MDI is a mixture of 4,4'-diphenylmethane diisocyanate and 2,4'-diphenylmethane diisocyanate in a weight ratio of 1:1.

[0054] The preparation method of described polymerizable macromolecular weight photoinitiator is as follows:

[0055] Equimolar amounts of 4-hydroxybenzophenone, MDI, and 2-hydroxyethyl acrylate were respectively prepared into toluene sol...

Embodiment 2

[0068] Similar to Example 1, a UV-curable hot-melt acrylate pressure-sensitive adhesive and the electrical tape prepared thereof are provided, but its preparation raw materials include 20 parts of acrylic resin, 20 parts of tackifying resin, and reactive diluent in parts by weight. 2 parts, 2 parts of vinyl monomer, 2 parts of softener, 0.1 part of antioxidant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com