Quick-drying explosion-proof high-strength wear-resistant castable

An explosion-proof, castable technology, applied in the field of refractory materials, can solve problems such as harsh environment, short construction period, complex structure, etc., and achieve the effects of avoiding bursting, shortening construction period and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

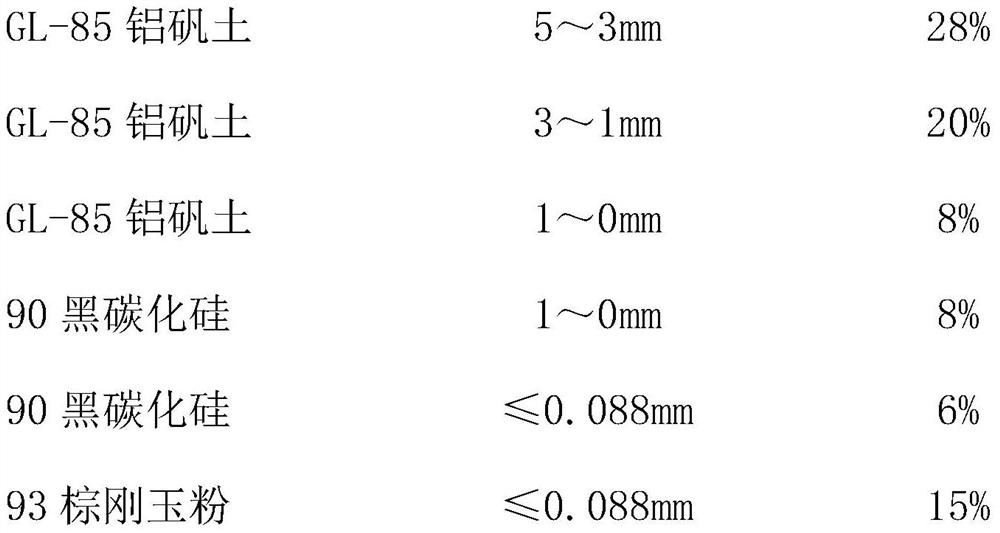

[0037] A fast-drying explosion-proof high-strength wear-resistant casting, prepared according to the following formula:

[0038]

[0039]

Embodiment 2

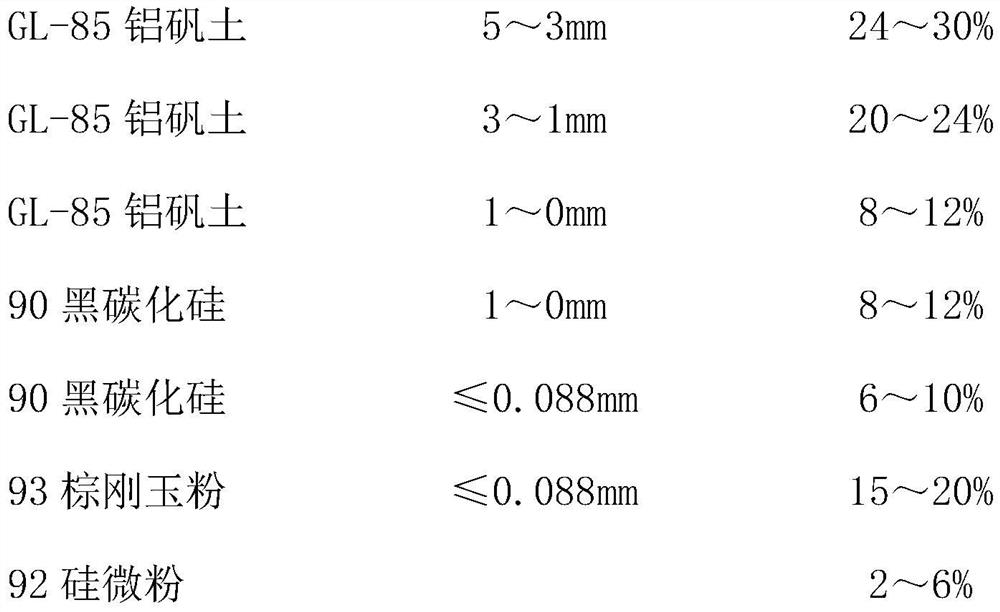

[0041] A fast-drying explosion-proof high-strength wear-resistant casting, prepared according to the following formula:

[0042]

Embodiment 3

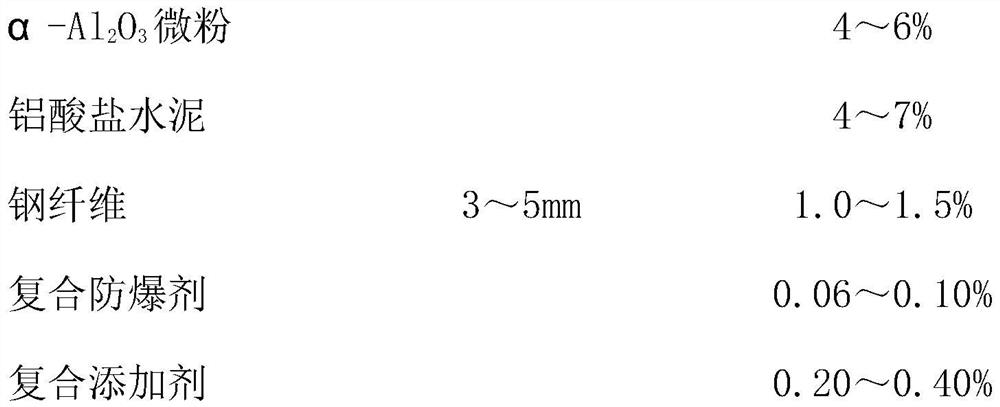

[0044] A fast-drying explosion-proof high-strength wear-resistant casting, prepared according to the following formula:

[0045]

[0046]

[0047] The components of the above examples are made into quick-drying and explosion-proof high-strength wear-resistant casting, and its performance parameters all meet the following standards:

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com