Autoclaved porous zeolite filter material having composite manganese and phosphorus removal effect and preparation method thereof

A porous zeolite and filter material technology, which is applied in the field of environmental water treatment, can solve the problems of expensive resin, high operating costs, and difficult regeneration, and achieve the effects of good effluent quality, reduced energy consumption, and mature production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation process and application results of the present invention are further illustrated below in conjunction with examples.

[0026] Principle of the present invention is:

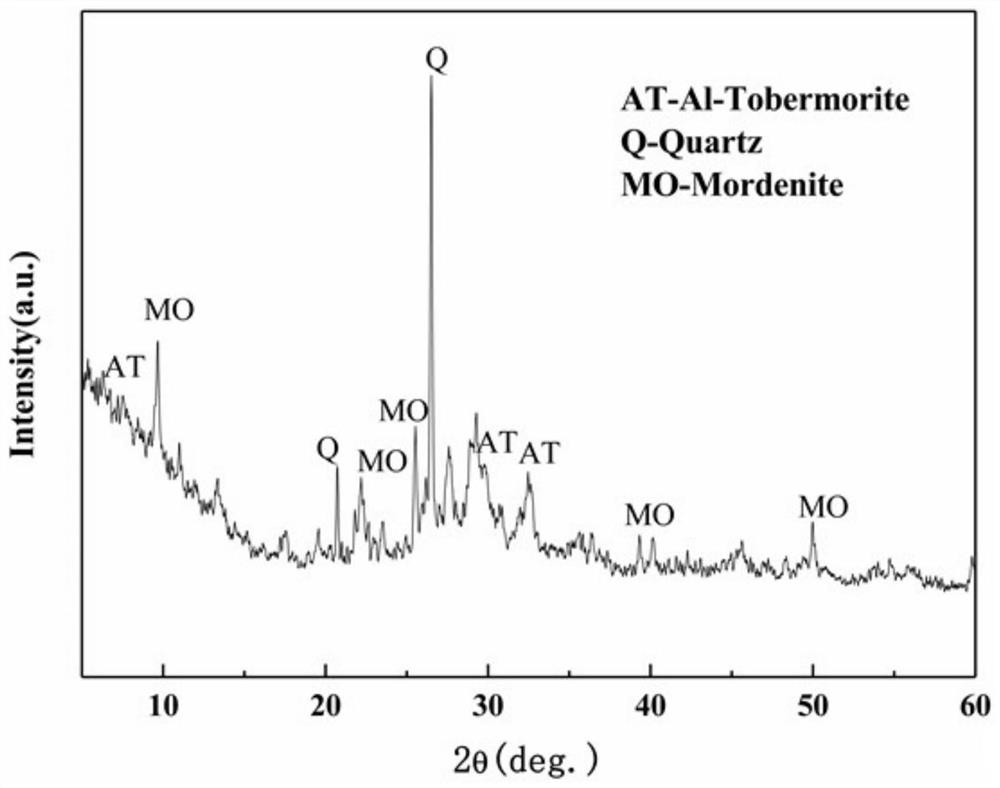

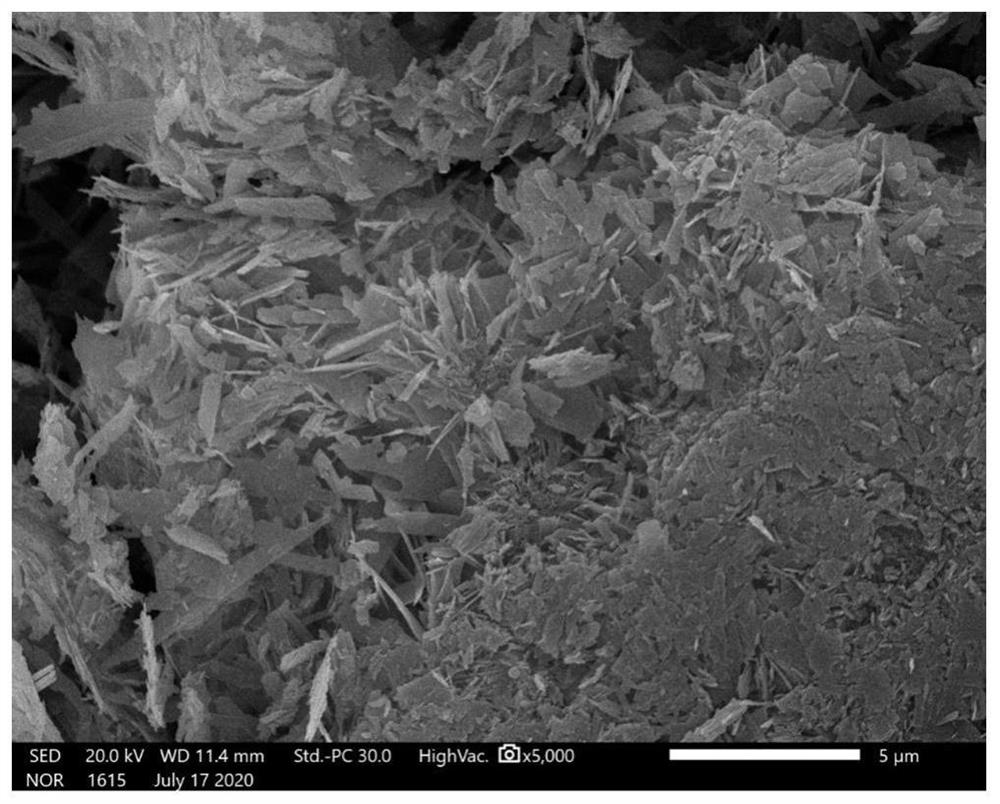

[0027] 1. Natural zeolite has a skeleton structure, and the most basic structural units constituting the zeolite skeleton are silicon-oxygen tetrahedron and aluminum-oxygen tetrahedron. Due to the diverse connection modes of silicon (aluminum) oxygen tetrahedra, many holes and channels are formed in the zeolite structure, but the holes and channels inside the natural zeolite structure are usually filled by water molecules and other impurities. The present invention selects hydrothermal synthesis to add Na when preparing autoclaved porous zeolite filter material 2 SO 4 solution, Na + Will replace other channels such as Mg 2+ The cation with larger equal radius makes the steric hindrance smaller, accelerates the internal diffusion, increases the exchange capacity, and improves the ion exc...

Embodiment example 1

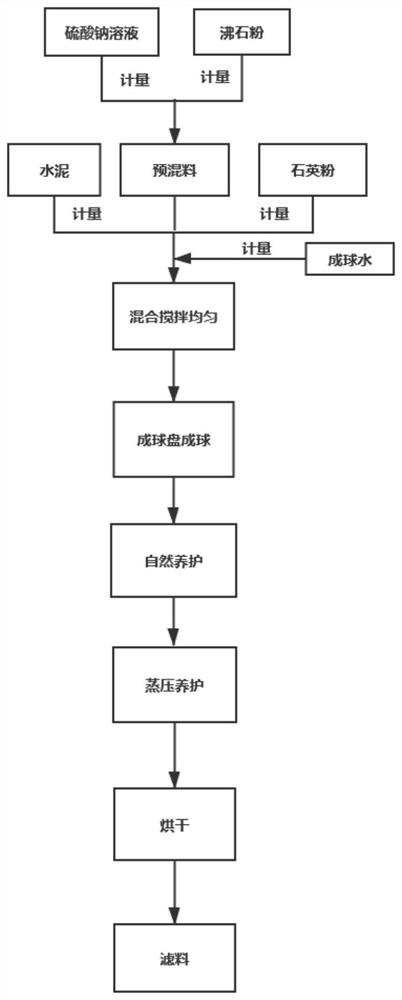

[0045] Implementation Case 1: Combining figure 1 , the preparation process of a kind of composite autoclaved porous zeolite filter material with manganese and phosphorus removal of the present invention is as follows:

[0046] In the first step, the natural zeolite is ground into a powder with a particle size of more than 100 mesh, and a powder with a particle size of quartz powder above 200 mesh;

[0047] The second step is to measure according to the quality of zeolite: quartz: cement=40kg: 30kg: 30kg;

[0048] The 3rd step, at first the 2wt%Na of 8kg is added in the natural zeolite powder of metering 2 SO 4 The solution is uniformly mixed, which is called zeolite premix; then the zeolite premix is mixed with measured quartz powder, cement, and 11kg of ball-forming water to form a mixture;

[0049] In the fourth step, the mixture is granulated into balls in the ball forming tray, and the particle size of the filter material is 3-8mm;

[0050] The fifth step is to carry...

Embodiment example 2

[0055] Implementation Case 2: Combining figure 1 , the preparation process of a kind of composite autoclaved porous zeolite filter material with manganese and phosphorus removal of the present invention is as follows:

[0056] In the first step, the natural zeolite is ground into a powder with a particle size of more than 100 mesh, and a powder with a particle size of quartz powder above 200 mesh;

[0057] The second step is to measure according to the quality of zeolite: quartz: cement=50kg: 25kg: 25kg;

[0058] The 3rd step, at first the 2wt%Na of 10kg is added in the natural zeolite powder of metering 2 SO 4 The solution is uniformly mixed, which is called zeolite premix; then the zeolite premix is mixed with measured quartz powder, cement, and 12kg of ball-forming water to form a mixture;

[0059] In the fourth step, the mixture is granulated into balls in the ball forming tray, and the particle size of the filter material is 3-8mm;

[0060] The fifth step is to carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com