A kind of cable and its production method

A production method and cable technology, applied in the direction of insulated cables, cable/conductor manufacturing, conductor/cable insulation, etc., can solve problems such as power supply safety hazards, poor moisture resistance of cables, aging of cable outer rubber, etc., to reduce impact and improve High temperature resistance, the effect of good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

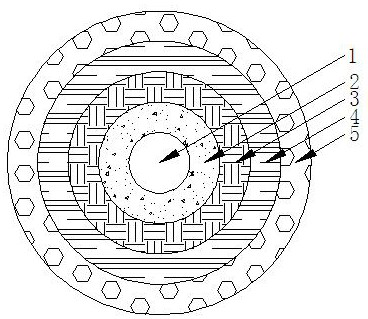

[0033] like figure 1 As shown, a cable, the cable includes a cable core 1, an insulating layer 2, a shielding layer 3, a strengthening layer 4 and an anti-corrosion layer 5 from the inside to the outside in sequence,

[0034] The insulating layer 2 is a rubber layer doped with a silica-wrapped alumina compound, and the insulating layer 2 includes the following raw materials in parts by weight:

[0035] 65 parts of high-density polyethylene, 12 parts of polyimide resin, 7 parts of flame retardant, 5 parts of sulfur, 6 parts of silica-coated alumina compound, 0.6 part of anti-aging agent RD, 0.6 part of anti-aging agent AW, stearin 1.2 parts of acid, 0.5 parts of accelerator CBS-80;

[0036] The shielding layer 3 is a metal braided mesh layer, and the reinforcement layer 4 is a steel strip;

[0037] The anti-corrosion layer 5 is a rubber layer doped with sericite and fiberglass, and the anti-corrosion layer 5 includes the following raw materials in parts by weight:

[0038] 6...

Embodiment 2

[0050] like figure 1 As shown, a cable, the cable includes a cable core 1, an insulating layer 2, a shielding layer 3, a strengthening layer 4 and an anti-corrosion layer 5 from the inside to the outside in sequence,

[0051] The insulating layer 2 is a rubber layer doped with a silica-wrapped alumina compound, and the insulating layer 2 includes the following raw materials in parts by weight:

[0052] 77 parts of high-density polyethylene, 18 parts of polyimide resin, 12.5 parts of flame retardant, 7 parts of sulfur, 8.5 parts of silica-coated alumina compound, 1.0 parts of anti-aging agent RD, 1.0 parts of anti-aging agent AW, stearin 2.5 parts of acid, 0.8 parts of accelerator CBS-80;

[0053] The shielding layer 3 is a metal braided mesh layer, and the reinforcement layer 4 is a steel strip;

[0054] The anti-corrosion layer 5 is a rubber layer doped with sericite and fiberglass, and the anti-corrosion layer 5 includes the following raw materials in parts by weight:

[00...

Embodiment 3

[0067] like figure 1 As shown, a cable, the cable includes a cable core 1, an insulating layer 2, a shielding layer 3, a strengthening layer 4 and an anti-corrosion layer 5 from the inside to the outside in sequence,

[0068] The insulating layer 2 is a rubber layer doped with a silica-wrapped alumina compound, and the insulating layer 2 includes the following raw materials in parts by weight:

[0069] 70 parts of high-density polyethylene, 16 parts of polyimide resin, 10 parts of flame retardant, 6.5 parts of sulfur, 7.5 parts of silica-coated alumina compound, 0.8 parts of anti-aging agent RD, 0.8 parts of anti-aging agent AW, stearin 2 parts of acid, 0.75 parts of accelerator CBS-80;

[0070] The shielding layer 3 is a metal braided mesh layer, and the reinforcement layer 4 is a steel strip;

[0071] The anti-corrosion layer 5 is a rubber layer doped with sericite and fiberglass, and the anti-corrosion layer 5 includes the following raw materials in parts by weight:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com