Water wall penetrating structure for low-temperature heating surface of tower furnace and installation method

A heating surface and wall structure technology, applied in boiler water pipes, combustion methods, steam boilers, etc., can solve problems such as difficult maintenance, reduce ash leakage, improve operating environment, and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

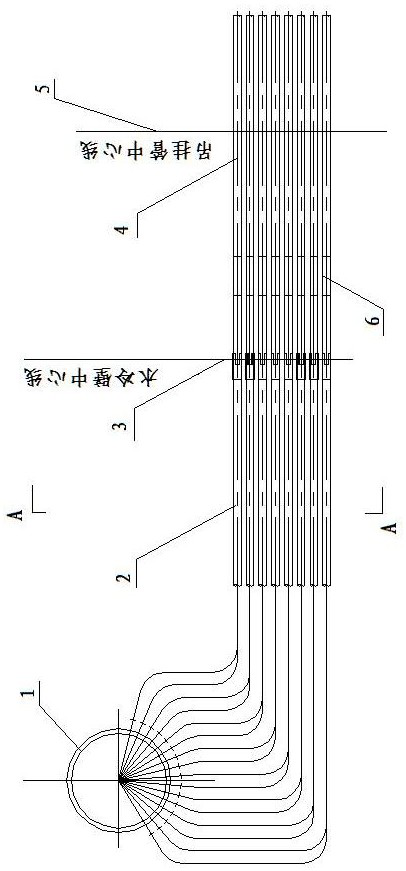

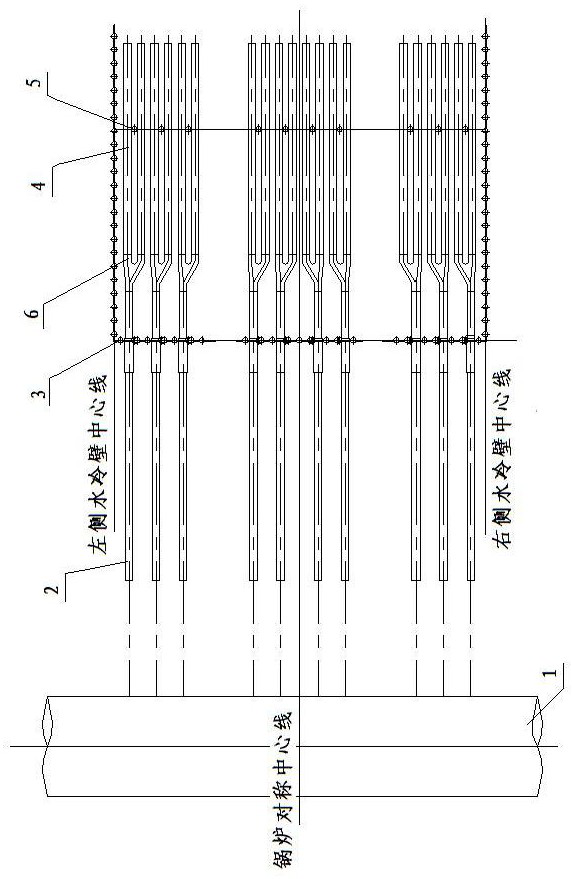

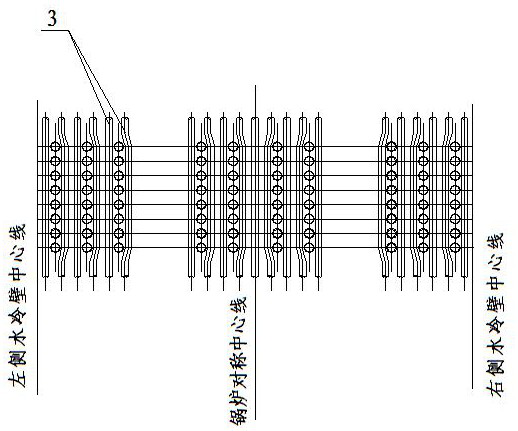

[0018] A structure for the low-temperature heating surface of a tower furnace to pass through the water-cooled wall, a set of low-temperature heating surface tubes 4, a set of low-temperature heating surface tubes passing through the low-temperature heating surface hanging tube 5 and connected to the low-temperature heating surface through an asymmetric tee 6 The diffuse pipe 2 on the heating surface is connected, and the diffuse pipe on the low-temperature heating surface passes through the water-cooled wall pipe 3 and is connected to the header 1. One end of the asymmetric tee is respectively connected to two low-temperature heating surface pipes, and the other end is connected to One of the low-temperature heating surface diffuser tubes, one of the low-temperature heating surface diffuser tubes passes between the two water-cooled wall tubes, and the water-cooled wall tubes are arranged in parallel and equidistant, wherein every other water-cooled wall tube The straight pipe ...

Embodiment 2

[0020] According to the structure described in Example 1 for the low-temperature heating surface of the tower furnace to pass through the water-cooled wall, two of the low-temperature heating surface tubes are passed between the two hanging tubes of the low-temperature heating surface, and the low-temperature heating surface The surface tubes, the diffuse tubes on the low-temperature heating surface, and the hanging tubes on the low-temperature heating surface are arranged in parallel and equidistant, and the water-cooled wall tubes are symmetrically arranged around the center of the boiler.

Embodiment 3

[0022] An installation method for the low-temperature heating surface of a tower furnace through a water-cooled wall structure described in Embodiment 1-2, the method includes the following steps:

[0023] After passing the low-temperature heating surface pipe through the last low-temperature heating surface hanging pipe, an asymmetric tee is used, in which the position of the branch pipe of the three-way is connected to the low-temperature heating surface pipe respectively, and between the two low-temperature heating surface pipes There is one low-temperature heating surface hanging pipe, the position of the three-way main pipe is connected to the low-temperature heating surface diffuse pipe, the low-temperature heating surface diffuse pipe at the center of the water-cooled wall passes through the water-cooled wall pipe, and the two described water-cooled wall pipes One of the upper and lower seals is a curved structure, and the bending size meets the low-temperature heating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com