Counter-force support structure for longitudinal dragging construction of steel beam and using method thereof

A technology of reaction force support and steel pipe support, which is applied in the direction of infrastructure engineering, bridges, bridge construction, etc., can solve the problems of too many pulling equipment and difficulty in ensuring the stroke maintenance of pulling equipment, and achieve clear force, continuity and displacement synchronization Sex, the effect of reducing the number of rows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

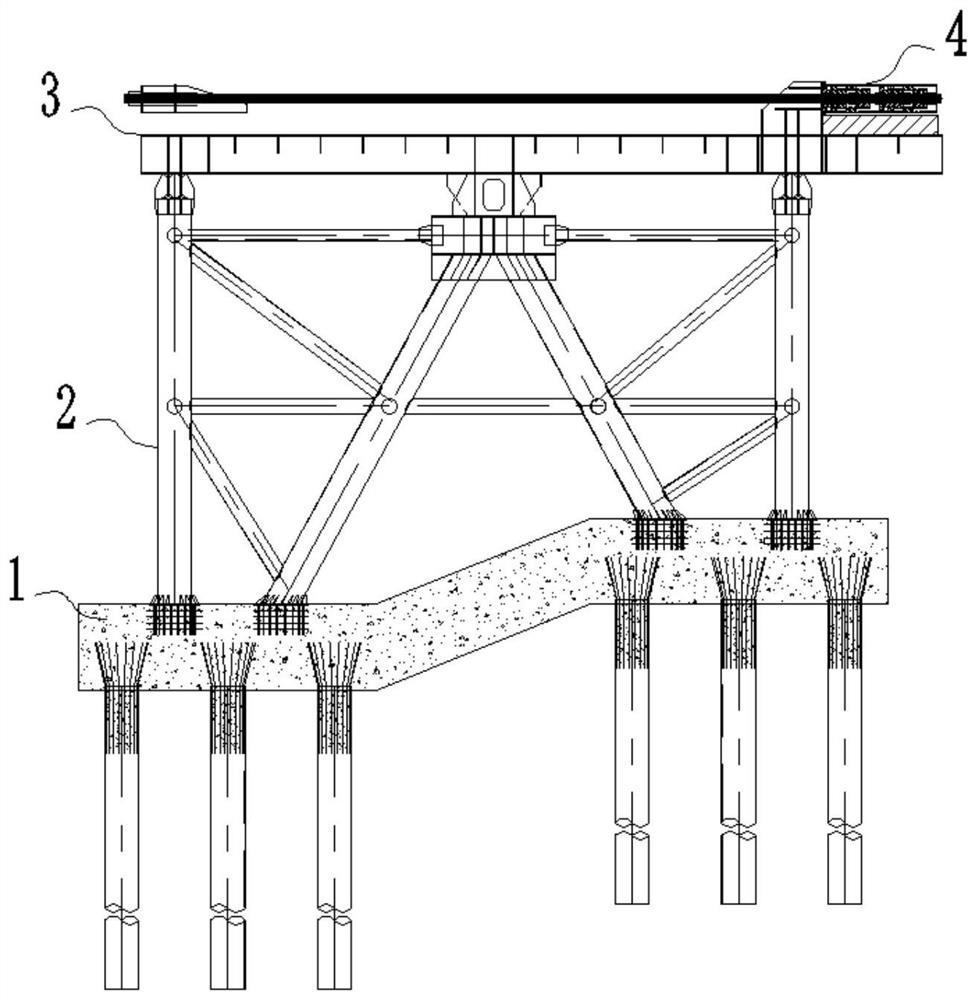

[0076] see Figure 1-9 As shown, the embodiment of the present application provides a reaction force support structure for steel beam longitudinal dragging construction, the reaction force support structure includes:

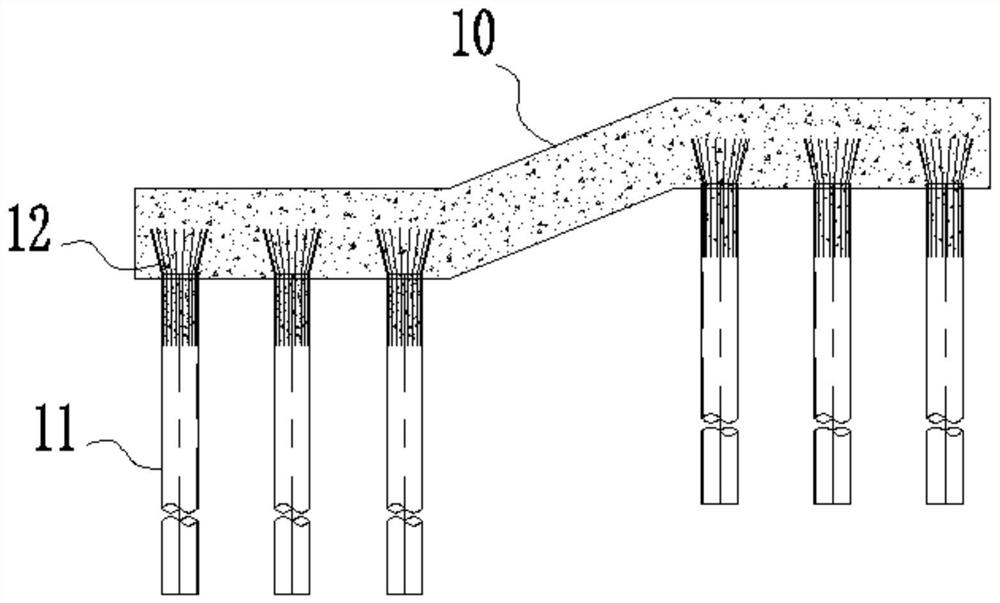

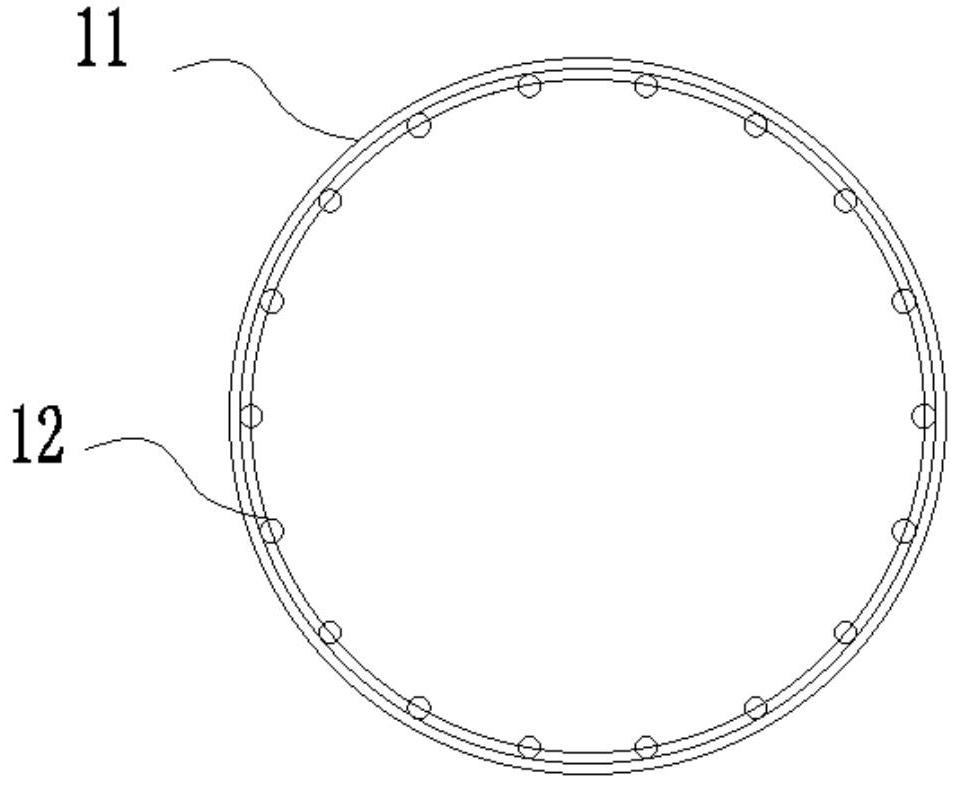

[0077] Foundation cap 1;

[0078] A plurality of steel pipe supports 2 arranged in pairs on the top surface of the foundation cap 1;

[0079] The slideway beam 3 arranged on the top surface of the steel pipe support 2;

[0080] The dragging system 4 arranged on one side of the top surface of the slideway beam 3, the dragging system 4 is used to drag the steel beam to be replaced on the top surface of the slideway beam 3; wherein,

[0081] The foundation cap 1 is a driven steel pipe pile foundation structure;

[0082] The steel pipe support 2 includes a vertical column structure and an inclined column structure.

[0083] In the embodiment of the present application, the steel pipe pile foundation and the cap are integrated to replace the traditional bored pil...

Embodiment 2

[0124] The embodiment of the present application provides a construction method of a reaction force support structure for steel beam longitudinal dragging construction, which is based on the reaction force support structure and its use method for steel beam longitudinal dragging construction mentioned in the first embodiment , the method includes the following steps:

[0125] S1, setting the foundation platform 1 in the preset area;

[0126] S2, multiple pairs of steel pipe supports 2 on the top surface of the foundation cap 1;

[0127] S3, setting the slideway beam 3 on the top surface of the steel pipe support 2;

[0128] S4, a dragging system 4 is set on one side of the top surface of the slideway beam 3;

[0129] S5. Use the dragging system 4 to drag the steel beam to be replaced to perform the beam replacement work; wherein,

[0130] The foundation cap 1 is a driven steel pipe pile foundation structure;

[0131] The steel pipe support 2 includes a vertical column struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com