Composite aerogel thermal insulation material as well as preparation method and application thereof

A technology of composite aerogel and thermal insulation material, which is applied in the field of composite aerogel thermal insulation material and its preparation, and can solve the problems of volume shrinkage, skeleton structure destruction, nanopore structure destruction and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

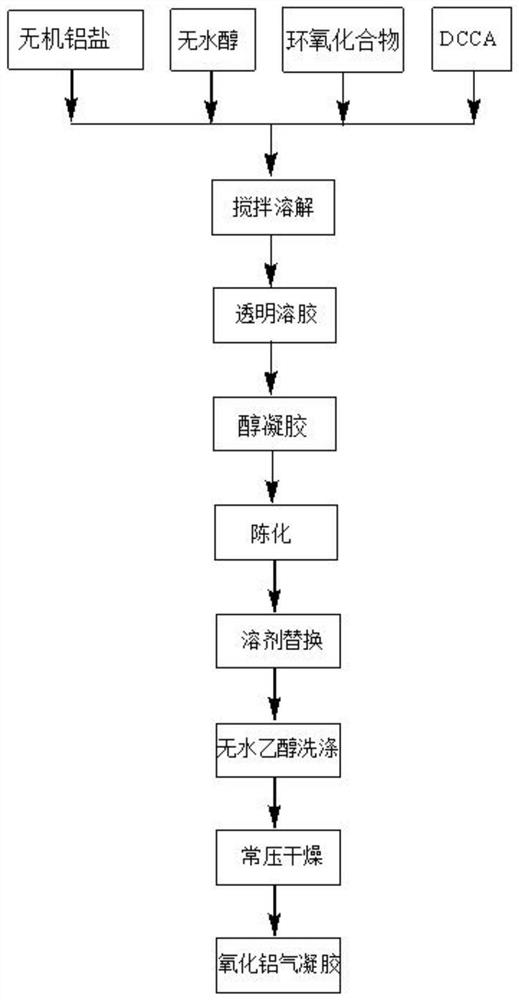

[0045] The invention provides a preparation method of a composite airgel thermal insulation material, comprising the following steps:

[0046] (1) SiO 2 Airgel and Al 2 o 3 The airgel is mixed and then ground to obtain a mixed powder;

[0047] (2) The mixed powder is mixed with water, and the obtained slurry is placed in a mold for thermal curing to obtain a composite airgel heat insulating material.

[0048] In the present invention, the SiO 2 The preparation method of airgel comprises the following steps:

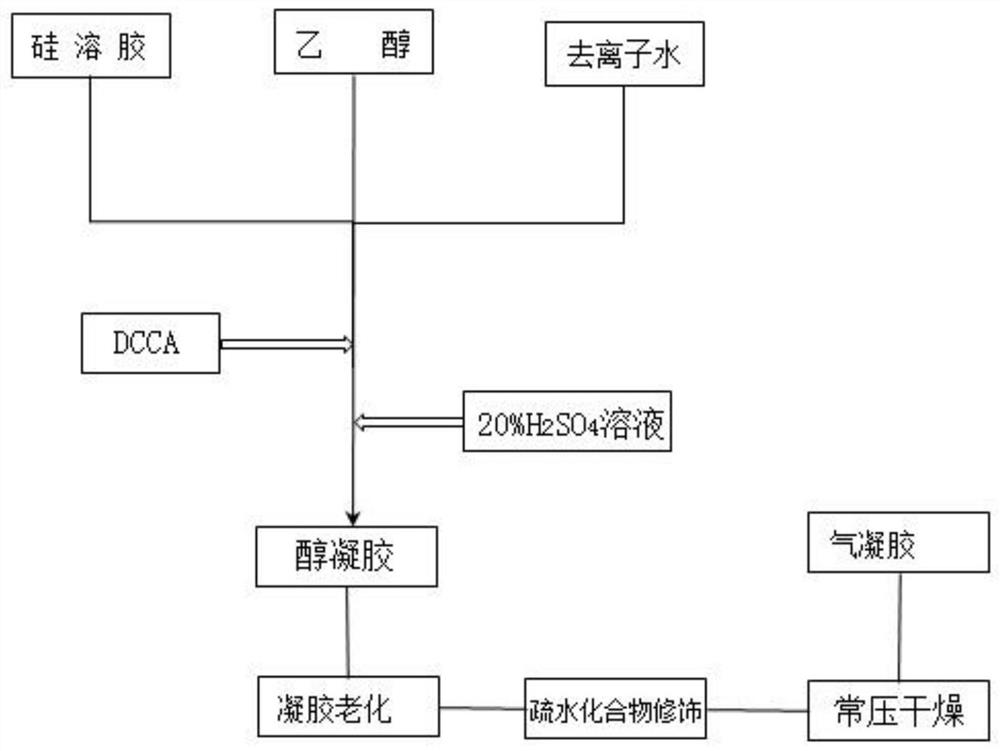

[0049] (1) Mix silica sol, ethanol, water and amide compounds, adjust the pH value of the mixed solution to 5-6, and then perform gelation treatment to obtain SiO 2 alcohol gel;

[0050] (II) the SiO 2 The alcohol gel was soaked in tetraethyl orthosilicate ethanol solution for aging to obtain aged SiO 2 alcohol gel;

[0051] (III) The aged SiO 2 The alcohol gel was soaked in the hydrophobic compound solution and then dried under normal pressure to obtain SiO 2 ...

Embodiment 1

[0082] Add 64mL silica sol (25%), 128mL ethanol, 8mL deionized water (namely silica sol: ethanol: water=32:64:4) in the beaker, add 2mL DCCA, adjust the pH value to 5 with 20wt% sulfuric acid solution , placed in a constant temperature water bath at 65°C for 2 hours to obtain SiO 2 alcohol gel. The resulting SiO 2 Alcohol gel was aged in 50mL ethanol / tetraethyl orthosilicate solution for 12h, then washed with absolute ethanol for 3 times, and the aged SiO 2 Alcohol gel uses n-hexane, isopropanol, trimethylchlorosilane mixed solution (the volume ratio of n-hexane, isopropanol, trimethylchlorosilane in the mixed solution is 10:10:1, trimethylchlorosilane The dosage is 35% of the molar amount of deionized water) soaked for 12h, then the gel after soaking was taken out and dried under normal pressure, the drying temperature was 65°C, and the time was 36h to obtain SiO 2 airgel.

Embodiment 2

[0084] Other conditions were the same as in Example 1, except that the drying temperature under normal pressure was changed to 45° C., and the drying time was changed to 72 hours.

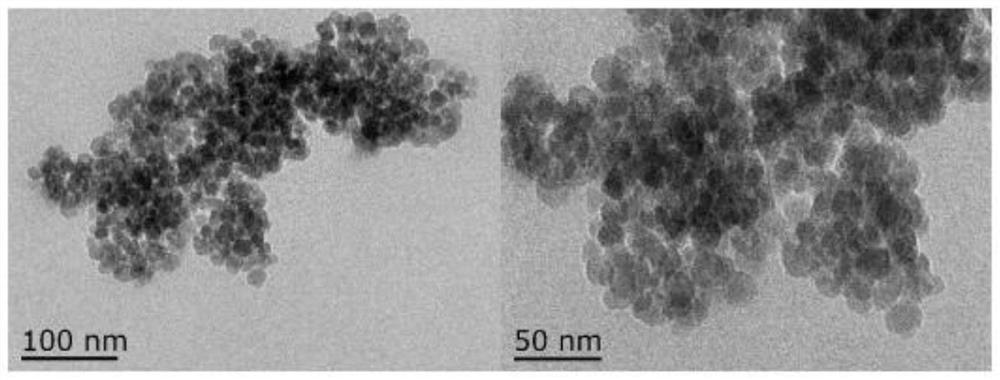

[0085] image 3 Be the obtained SiO of embodiment 1 2 The TEM image of the airgel, where the left side is the TEM image with a scale of 100nm, and the right side is a TEM image with a scale of 50nm; Figure 4 Gained SiO for embodiment 2 2 TEM image of the airgel, Figure 4The left and right are SiO in different aggregation states 2 The TEM image of the airgel, the scale bar is 50nm. according to Figure 3-4 It can be seen that the SiO prepared in Examples 1-2 2 The airgel particles are uniform.

[0086] Figure 5 Gained SiO for embodiment 2 2 The SEM image of the airgel, in which the SEM image with a scale of 1 μm is on the left, and the SEM image with a scale of 300 nm is on the right. according to Figure 5 It can be seen that the SiO prepared by the present invention 2 Airgel Airgel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com