MXene-based three-dimensional porous flexible self-supporting membrane, preparation method thereof and application of membrane in electrochemical adsorption of dyes

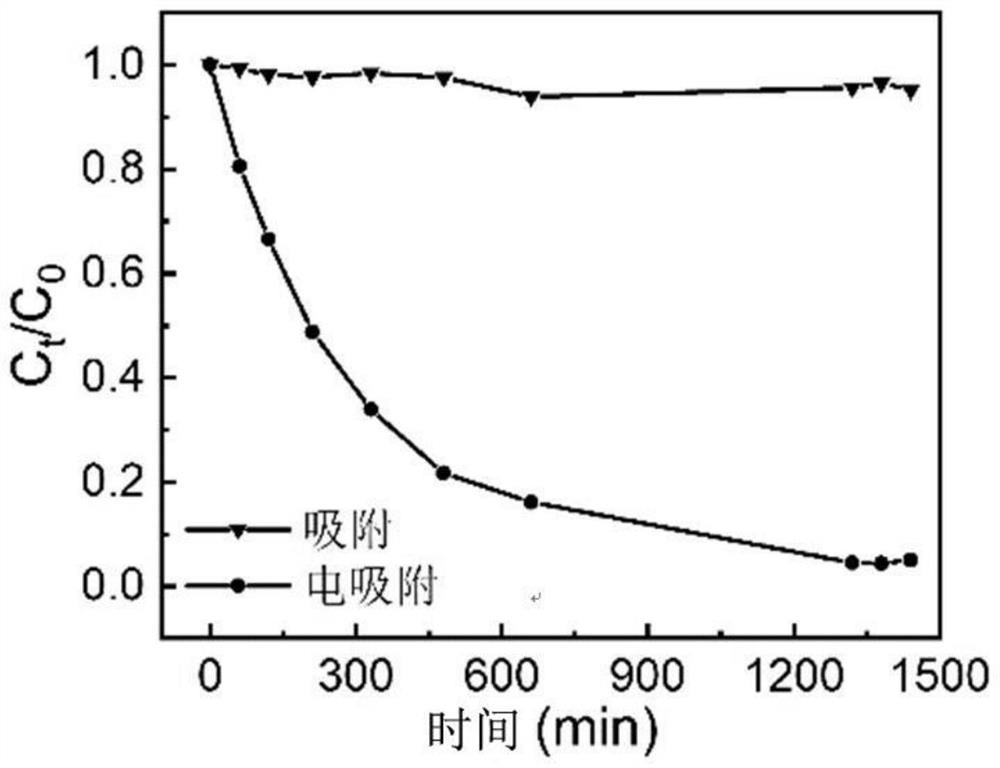

A three-dimensional porous, self-supporting membrane technology, applied in other chemical processes, separation methods, inorganic chemistry, etc., can solve the problems of small pore size, low specific surface area, and low adsorption performance of MXene nanofiltration membranes, and achieve easy recycling and improvement. Specific surface area, the effect of enhancing electrostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

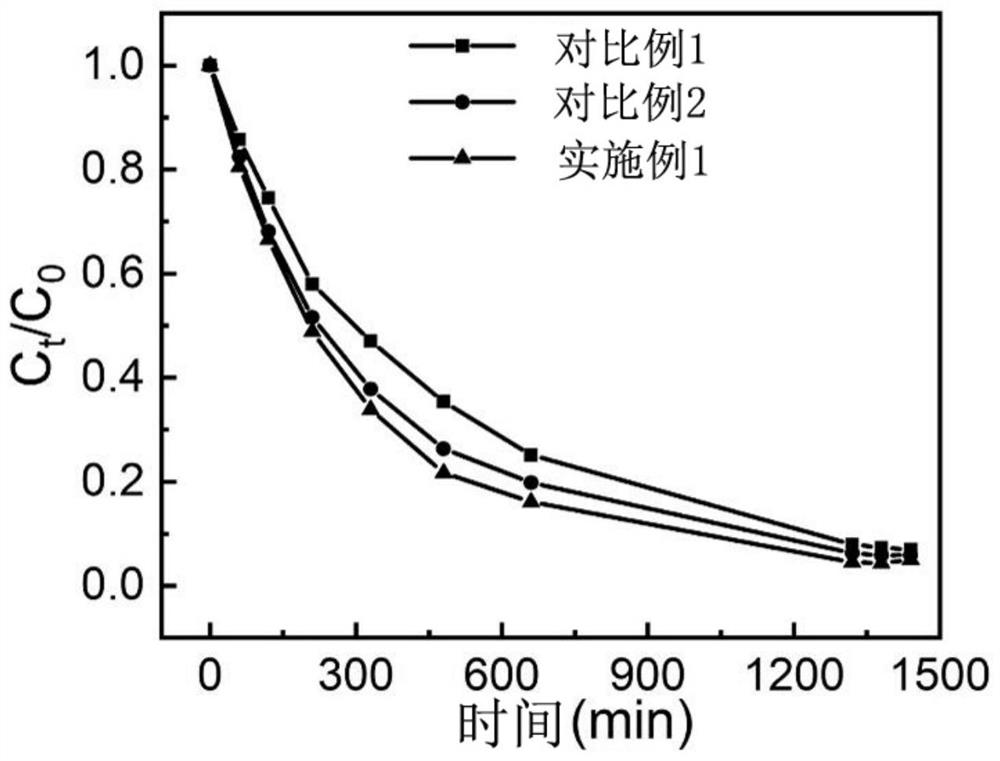

Embodiment 1

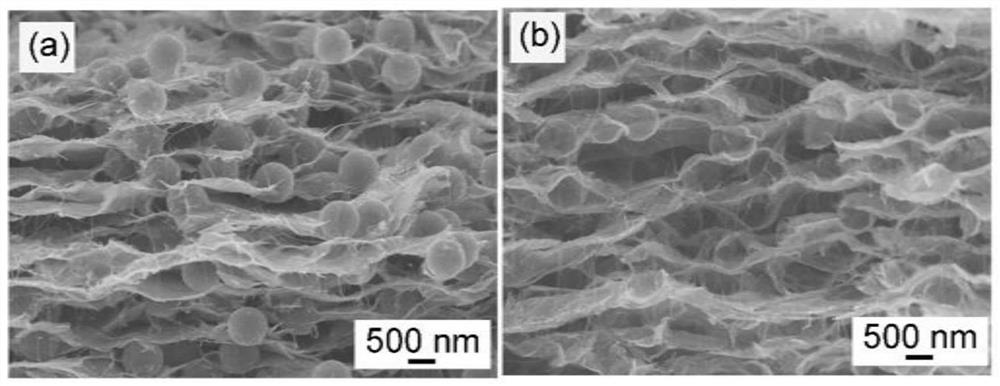

[0037] A kind of preparation method of MXene-based three-dimensional porous flexible self-supporting film, comprises steps as follows:

[0038] (1) Preparation of MXene nanosheet suspension

[0039] Add 2.5g LiF to 20mL HCl solution with a concentration of 6mol / L, stir evenly to obtain a mixed solution, and then add 2g Ti 3 AlC 2 Add it to the above mixed solution and react at 40°C for 48h; after the reaction, centrifuge and wash with deionized water until the pH of the supernatant is 6, vacuum dry the obtained solid at 60°C for 48h, then add deionized water for ultrasonic 90min, then centrifuged at 3500rpm for 60min, the resulting supernatant was Ti 3 C 2 T x MXene nanosheet suspension; known volume of Ti by suction filtration 3 C 2 T x After MXene nanosheet suspension and freeze-drying, the weight of the film was measured to calculate its concentration as 2mg / mL.

[0040] (2) Preparation of polystyrene microsphere suspension

[0041] Add 15mL of styrene and 1.5mL ...

Embodiment 2

[0050] A kind of preparation method of MXene-based three-dimensional porous flexible self-supporting membrane is as described in Example 1, the difference is: in step (3), the Ti concentration prepared by 10mL step (1) is 2mg / mL 3 C 2 T x MXene nanosheet suspension, the concentration of 1mL step (2) prepared is the polystyrene microsphere suspension of 5mg / mL, 1mL concentration is the single-walled carbon nanotube suspension of 1mg / mL and mixes evenly, and the gained mixture is carried out Ultrasonic treatment for 30min, followed by vacuum filtration, the filtration pressure is 0.1MPa, the filter membrane is cellulose membrane, the obtained product and the filter membrane are freeze-dried at -47°C for 12h, the product falls off from the filter membrane, and MXene / PS is obtained / SWCNTs composite film.

Embodiment 3

[0052] A preparation method of MXene-based three-dimensional porous flexible self-supporting membrane is as described in Example 1, the difference is: in step (2), 10mL styrene and 1.5mL acrylic acid are added to 150mL ultrapure water, and heated to 80°C , adding 9mL mass concentration of 1.0wt% ammonium persulfate (APS) aqueous solution, the addition rate of ammonium persulfate (APS) aqueous solution is 10min / mL, then react at 90°C for 24h; after the reaction is completed, filter, and use the obtained precipitate Washing with deionized water three times and drying to obtain polystyrene (PS) microspheres with uniform size; the particle diameter of the obtained PS microspheres is 0.2-0.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com