Impedance test method for lithium separation detection of lithium ion battery

A lithium-ion battery, impedance testing technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of battery follow-up testing that destroys the integrity of the battery, and the monitoring of lithium behavior that cannot be analyzed, so as to prevent the loss of active materials and The effect of interface degradation, improved service life, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

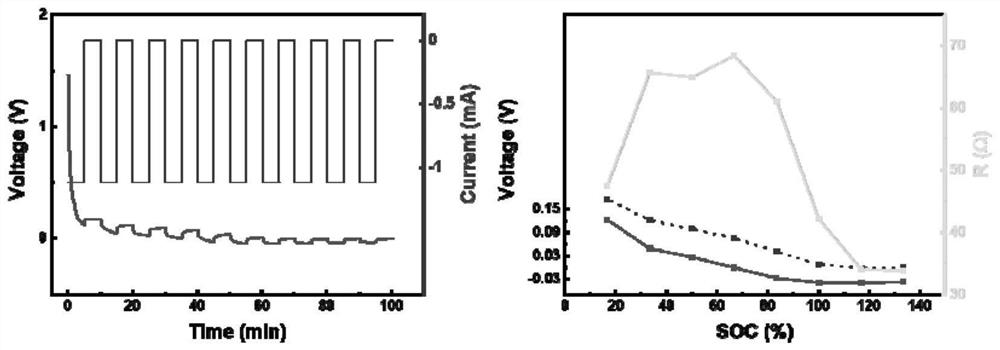

[0036] Example 1 Determining whether the negative electrode has lithium-analysis behavior under the lithium-graphite (Li-Graphite) half-cell system

[0037] (1) Production of the reference electrode: Select an enamelled copper wire with a diameter of 130 μm, remove the polymer coating with a suitable length at both ends, wind one end with a 30 μm lithium sheet with a suitable length, and bend it into a ring after wrapping lithium , the other end does not process;

[0038](2) Li-Graphite three-electrode half-cell assembly: the graphite negative electrode uses mesocarbon microspheres (MCMB), according to the ratio of MCMB: conductive carbon black (Supper P): polyvinylidene fluoride (PVDF) = 8:1:1 Prepare a slurry in a certain amount of N-methylpyrrolidone and mix it evenly. The slurry is coated on a copper foil with a scraper and dried in a blast dryer for 24 hours. A graphite negative electrode circle with a diameter of 13mm is punched by a punching machine. Shaped pole piece;...

Embodiment 2

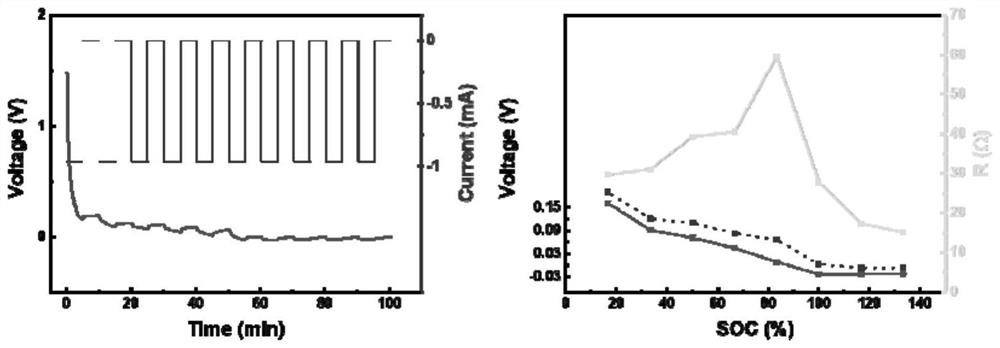

[0041] Lithium analysis behavior in embodiment 2 full battery

[0042] (1) Production of the reference electrode: Select an enamelled copper wire with a diameter of 130 μm, remove the polymer coating with a suitable length at both ends, wind one end with a 30 μm lithium sheet with a suitable length, and bend it into a ring after wrapping lithium , the other end does not process;

[0043] (2) Graphite negative electrode full battery assembly: choose ternary material (NCM) as the positive electrode material, and the coated surface capacity is 2mA h cm -2 The positive pole piece was punched into a disc with a diameter of 13mm after being dried in a blast drying oven. The graphite negative electrode is prepared according to the proportion of the slurry and then scraped to obtain a surface capacity of 0.6mA h cm -2 The negative pole piece is punched into a disc with a diameter of 13mm after being dried in a blast drying oven. The reference electrode is placed between the positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com