A new al-mg-si aluminum alloy energy-absorbing material for collision and its preparation method

A technology of energy-absorbing materials and aluminum alloys, which is applied in the field of aluminum alloy materials to achieve the effects of alleviating supersaturation, improving safety, and improving energy-absorbing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

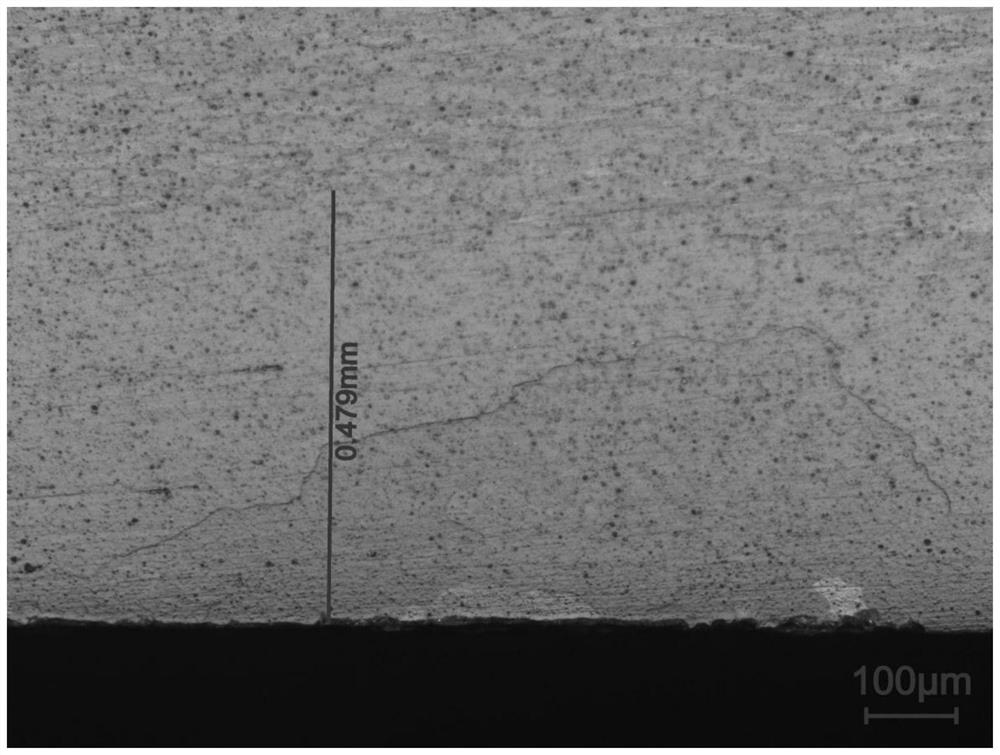

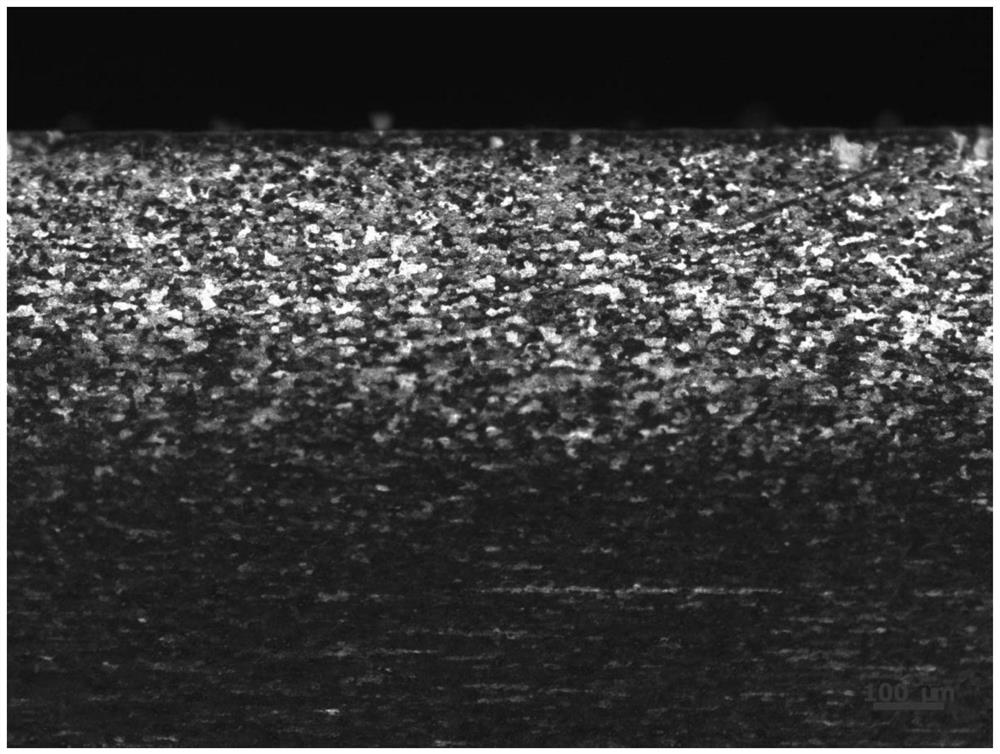

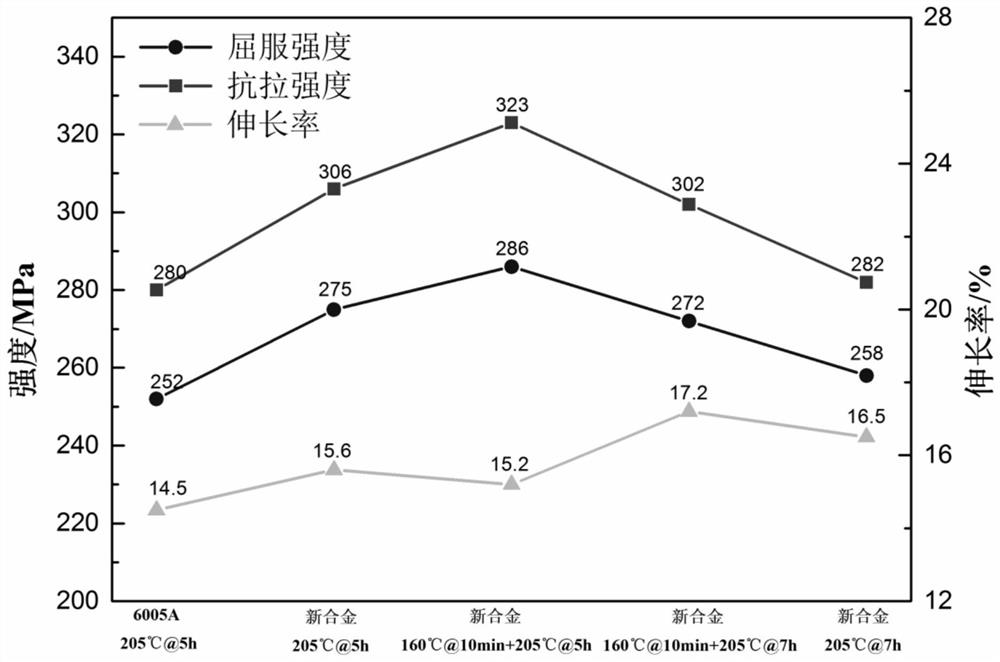

[0032] A method for preparing a novel Al-Mg-Si aluminum alloy energy-absorbing material for collision, comprising the following steps: Aluminum ingot preparation: preparing an aluminum ingot according to the composition ratio of the Al-Mg-Si aluminum alloy energy-absorbing material; homogenizing heat treatment: The temperature is 575±5°C, the time is 4.5±0.5h, the heating rate is 80±1°C / h, and it is cooled directly after being out of the furnace, and the cooling rate is greater than 10°C / min; extrusion processing: extrude aluminum ingots with extrusion dies The profile is obtained by pressing; aging treatment: the extruded profile is pre-aged within 4±0.5h, and then artificially aged. The temperature of the treatment is 205±3°C, and the time is 7±0.5h.

[0033] In the present invention, online quenching treatment is directly carried out after extrusion processing, short-time pre-aging treatment is directly carried out after online quenching treatment, and the process of short-...

Embodiment

[0041] A kind of preparation method of Al-Mg-Si aluminum alloy energy-absorbing material for novel collision, comprises the following steps:

[0042] Ingredients: Calculate the amount of each aluminum alloy raw material and prepare the aluminum alloy raw material according to the ratio, so that the mass percentage of the alloy composition is controlled at: Si: 0.65-0.85%, Fe≤0.15%, Cu: 0.30-0.35, Mn: 0.60-0.75%, Mg : 0.65-0.75%, Cr: 0.20-0.30%, Ti ≤ 0.1%, the content of other individual impurities ≤ 0.05%; the total of other impurities ≤ 0.15%; the balance is Al.

[0043] Melting and casting: using the conventional semi-continuous casting method, casting cast rods.

[0044] Homogenization heat treatment: (575±5℃x4.5h), the heating rate is 80±1℃ / h, the ingot temperature is monitored in real time during the heating process, water cooling is performed directly after the furnace is released, the cooling rate is greater than 10℃ / min, and the lathe after cooling Car remove the 5mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com