Novel flame retardant for polyolefin and preparation method of flame retardant

A flame retardant and polyolefin technology, which is applied in the field of flame retardants and can solve the problems of large amount of addition, low carbon formation, and low thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

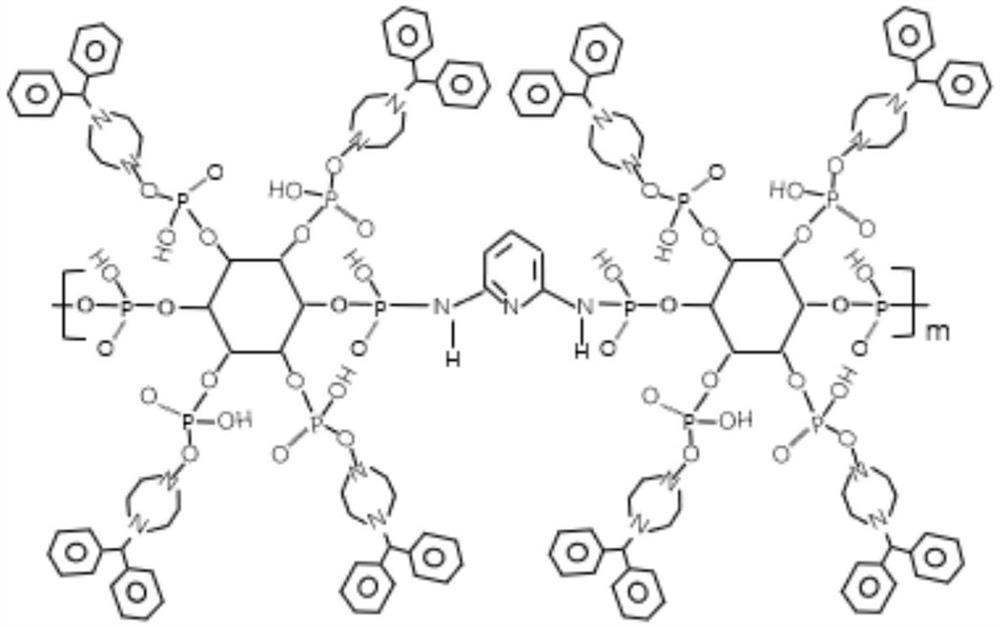

[0026] This example provides a new type of flame retardant for polyolefin, and the structural formula of the flame retardant is:

[0027]

[0028] where m is a positive integer from 1 to 100.

Embodiment 2

[0030] A preparation method of a novel flame retardant for polyolefins of the present invention comprises the following steps: a. In mole parts, add 2 parts of phytic acid to 5 parts of water, and stir to fully dissolve;

[0031] b. 7.6 parts of diphenylmethylpiperazine are heated to melt at 90°C, and 0.8 parts of 2,6-diaminopyridine are heated to melt at 120°C;

[0032] c, in the mixture obtained in step a, dropwise step b material respectively, and stir;

[0033] d. Adjust the solution system obtained in step c with ammonia water to a pH of 6. After the dropwise addition is completed, the temperature is raised to 80 ° C and the reaction is continued for 2 h. After cooling to room temperature, the white precipitated intermediate is obtained by filtration;

[0034] e. The intermediate obtained in step d is heated to 250°C under an inert gas condition, and the reaction product is obtained after dehydration and condensation reaction for 1 h;

[0035] f. The obtained reaction pr...

Embodiment 3

[0037] A preparation method of a novel flame retardant for polyolefin of the present invention comprises the following steps:

[0038] a, in mole parts, to 10 parts of water, add 2 parts of phytic acid, stir to make it fully dissolved;

[0039] b. 8 parts of diphenylmethylpiperazine are heated to melt at 95°C, and 1 part of 2,6-diaminopyridine is heated to melt at 125°C;

[0040] c, in the mixture obtained in step a, dropwise step b material respectively, and stir;

[0041] d. Adjust the solution system obtained in step c with ammonia water to a pH of 8. After the dropwise addition is completed, the temperature is raised to 90° C. to continue the reaction for 2 h, and after cooling to room temperature, a white precipitated intermediate is obtained by filtration;

[0042] e. The intermediate obtained in step d is heated to 260° C. under an inert gas condition, and the reaction product is obtained after dehydration and condensation reaction for 1 h;

[0043] f. The obtained re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com